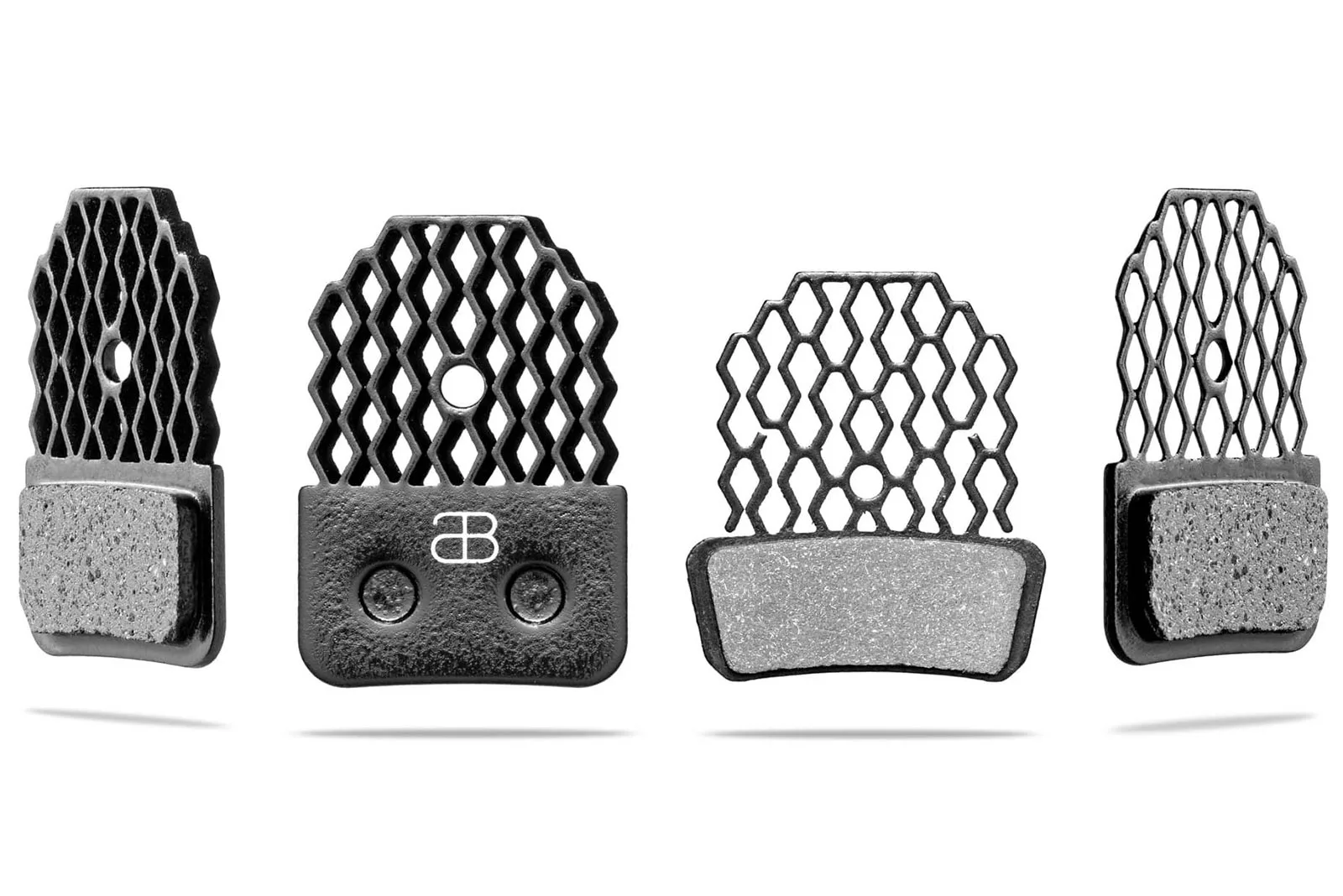

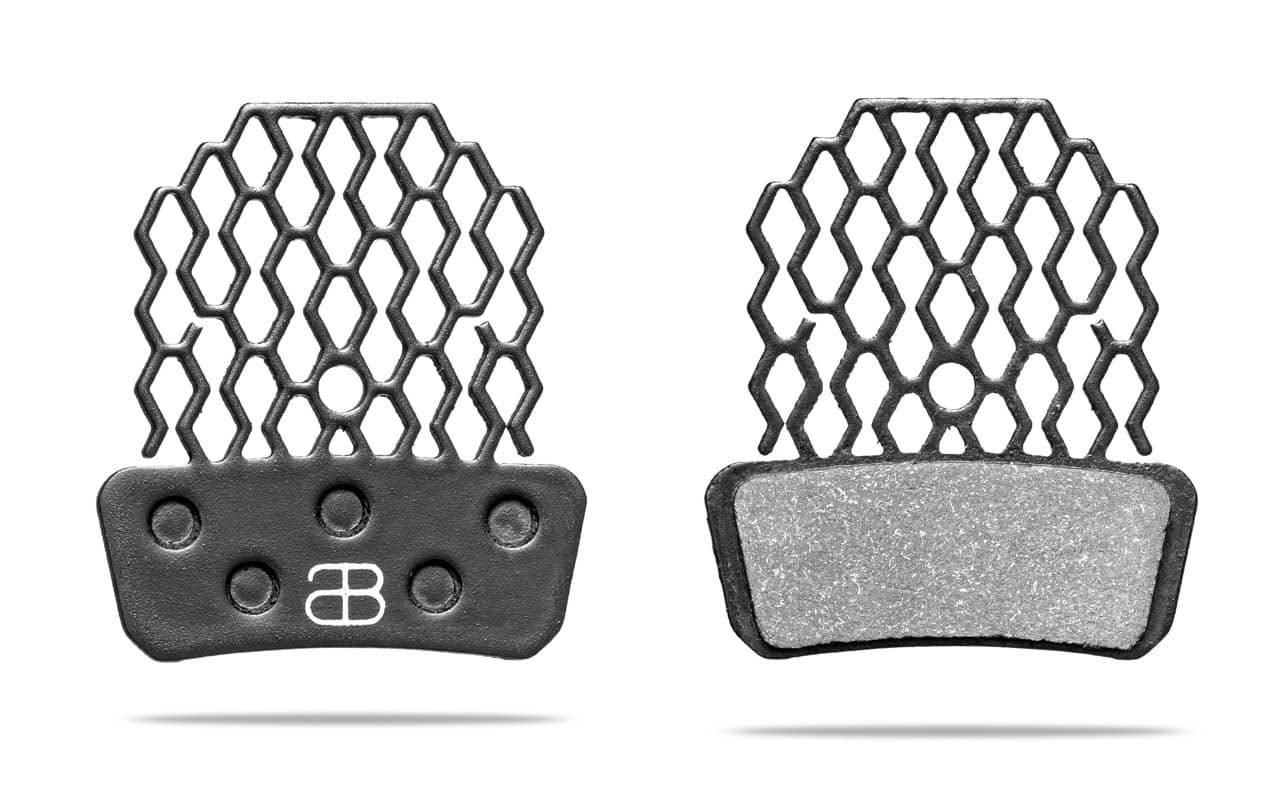

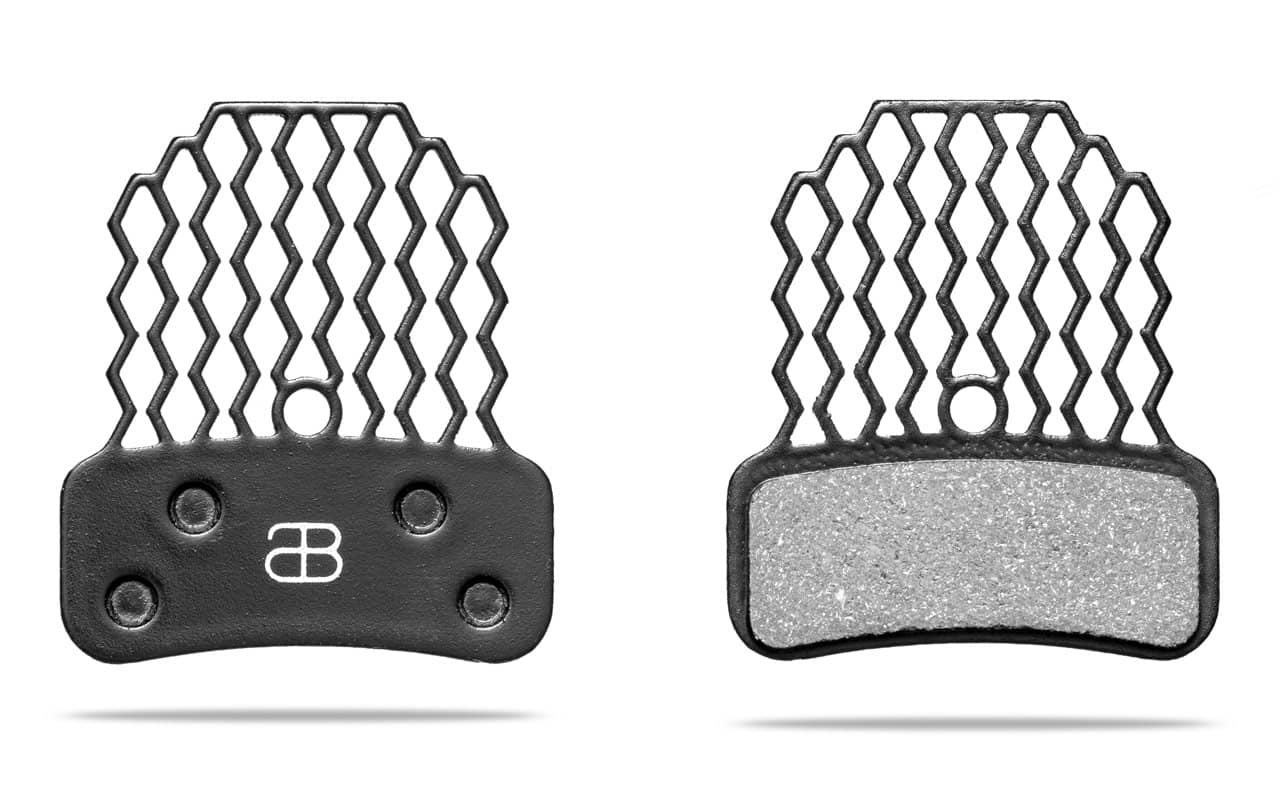

The new absoluteBLACK GRAPHENpads disc brake pads use an all-new combination of graphene-coated-and-finned back plates and graphene-infused pad compounds to reduce heat and prevent brake fade.

After three years of development and testing, they say these new brake pads offer up to 35% better braking performance by keeping them much cooler during prolonged descents. Their research showed that heat buildup was the number one reason for reduced braking performance, so the combination of materials and design promise to keep initial bite and power modulation consistent even in heavy use.

The pad compound uses a “specially modified graphene” which offers good friction and durability while also transferring heat to the backing plates more efficiently. And, it’s free of copper, which they note becomes dust during braking, and that dust is toxic to marine life and will be banned in California starting in 2025. It’s also quiet.

absoluteBLACK developed and is manufacturing their pads and compounds in Europe, drawing on automotive tech that’s already seeing graphene used as a higher-performance copper alternative.

The graphene-coated steel backing plates use a patented angled cut on the finned radiators to pull heat up and away from the pads and calipers. The shapes and designs of the fins vary by model and come on all versions except for Shimano Deore brakes.

As they explain further down, air flow is key to temperature regulation, but they say graphene’s extremely high thermal conductivity is what pulls so much more heat away from the pads and up to the fins for quicker, more complete cooling.

GRAPHENpad models & pricing

The absoluteBLACK GRAPHENpads brake pads will be offered in five versions, all prices are per wheel:

- Disc 34 – For Shimano Dura-Ace ($62.99 / £49.99 / €59.99)

- Disc 35 – For SRAM eTap AXS ($62.99 / £49.99 / €59.99)

- Disc 27 – For Shimano XTR ($49.99 / £39.99 / €47.99)

- Disc 31 – For SRAM G2 ($49.99 / £39.99 / €47.99)

- Disc 15 – For Shimano Deore ($37.99 / £29.99 / €35.99)

The 34/35 models use a performance road compound, while the others use an endurance mountain bike compound. All pads will fit any caliper with a compatible pad size and shape (i.e. SRAM AXS pads fit any of their current 2-piston road calipers for RED, Force, Rival, etc.).

The Deore-compatible pads do not get fins because of fitment constraints.

Lab testing graphene brake pads for cycling

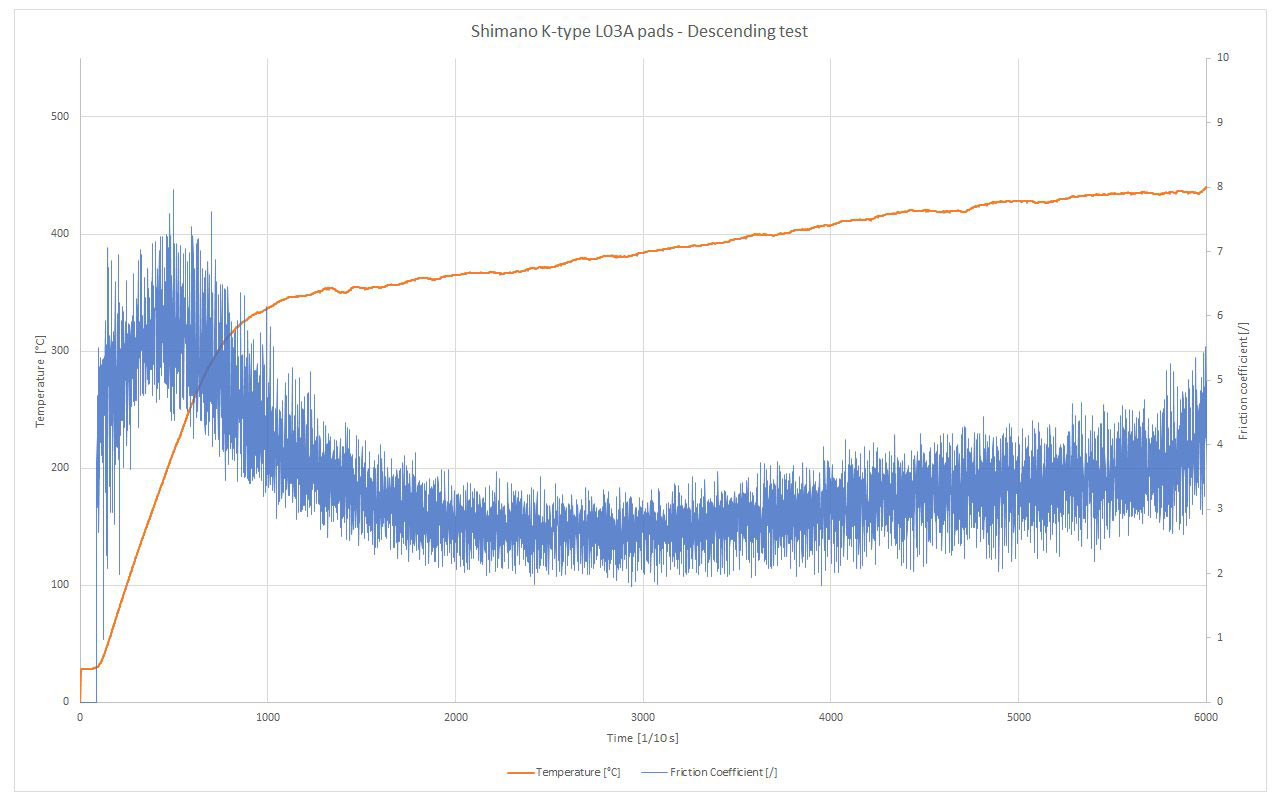

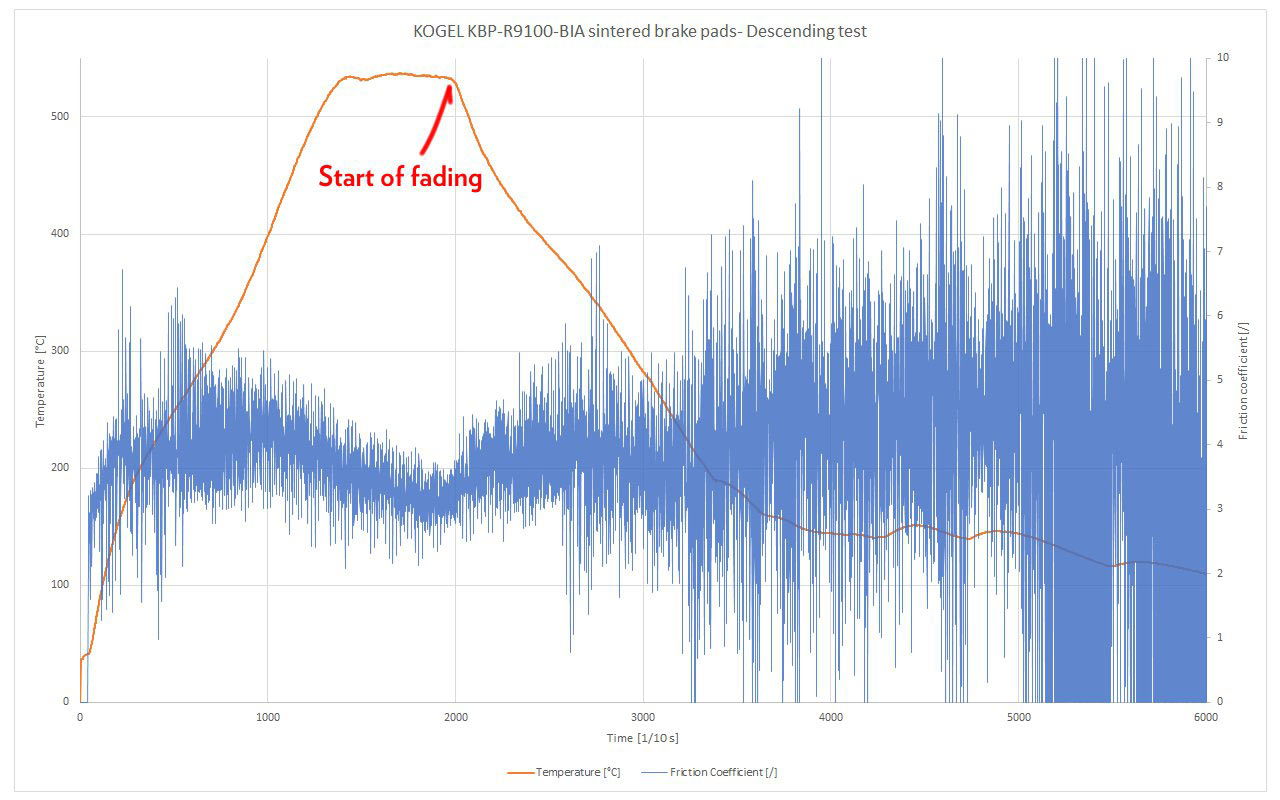

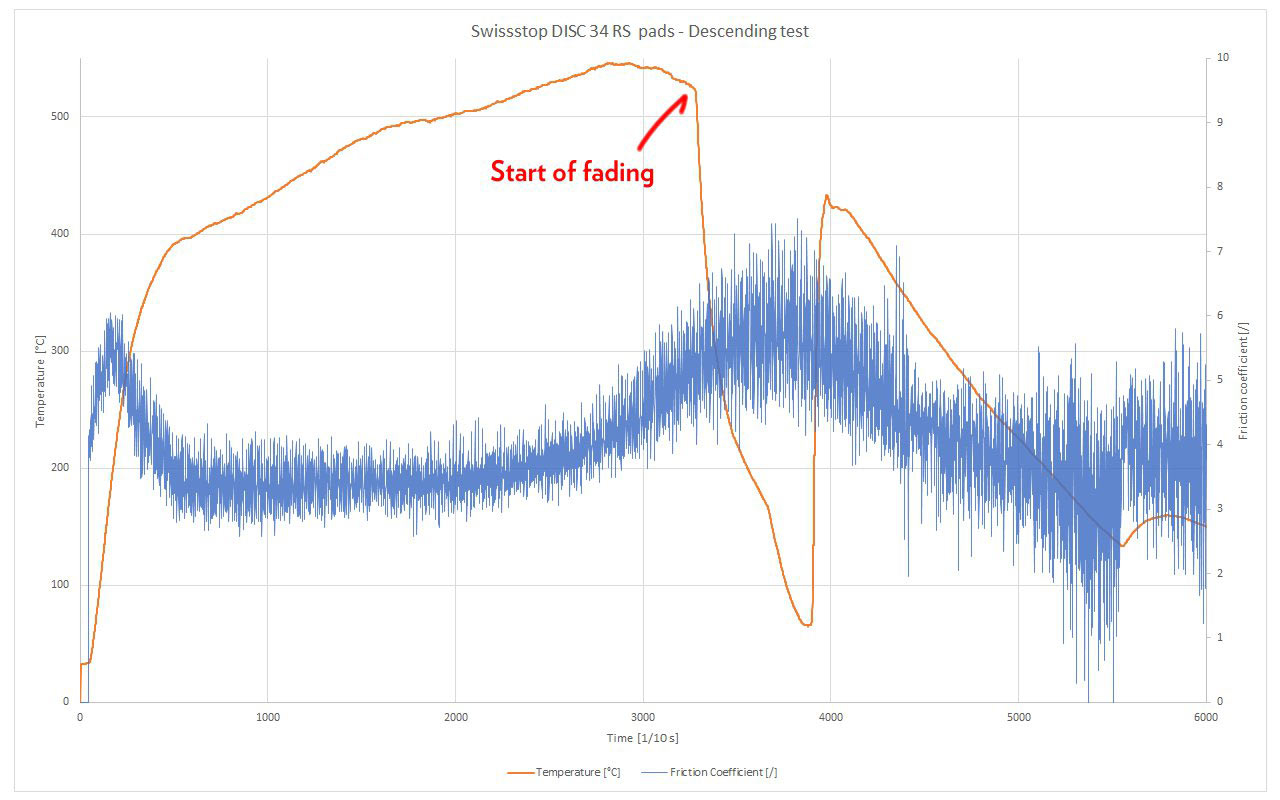

absoluteBLACK provided us with their testing data, which we’re posting below unedited for your information only. The big takeaway is that heat is bad for braking performance, and keeping pad temps under 400ºC maintains power and modulation without brake fade. And their new compound and design seems to do that. They also conducted a Progressive Braking Test, with results posted on the product pages for each brake pad.

IMPORTANT NOTE: The GRAPHENpads are a self-described “ceramic organic” pad compound. The Shimano and SwissStop pads are organic, and the Kogel pads are Sintered, which were included to provide perspective on the different compound’s braking properties. So, this is NOT and apples-to-apples test in that regard and the results should evaluated in context.

From absoluteBLACK:

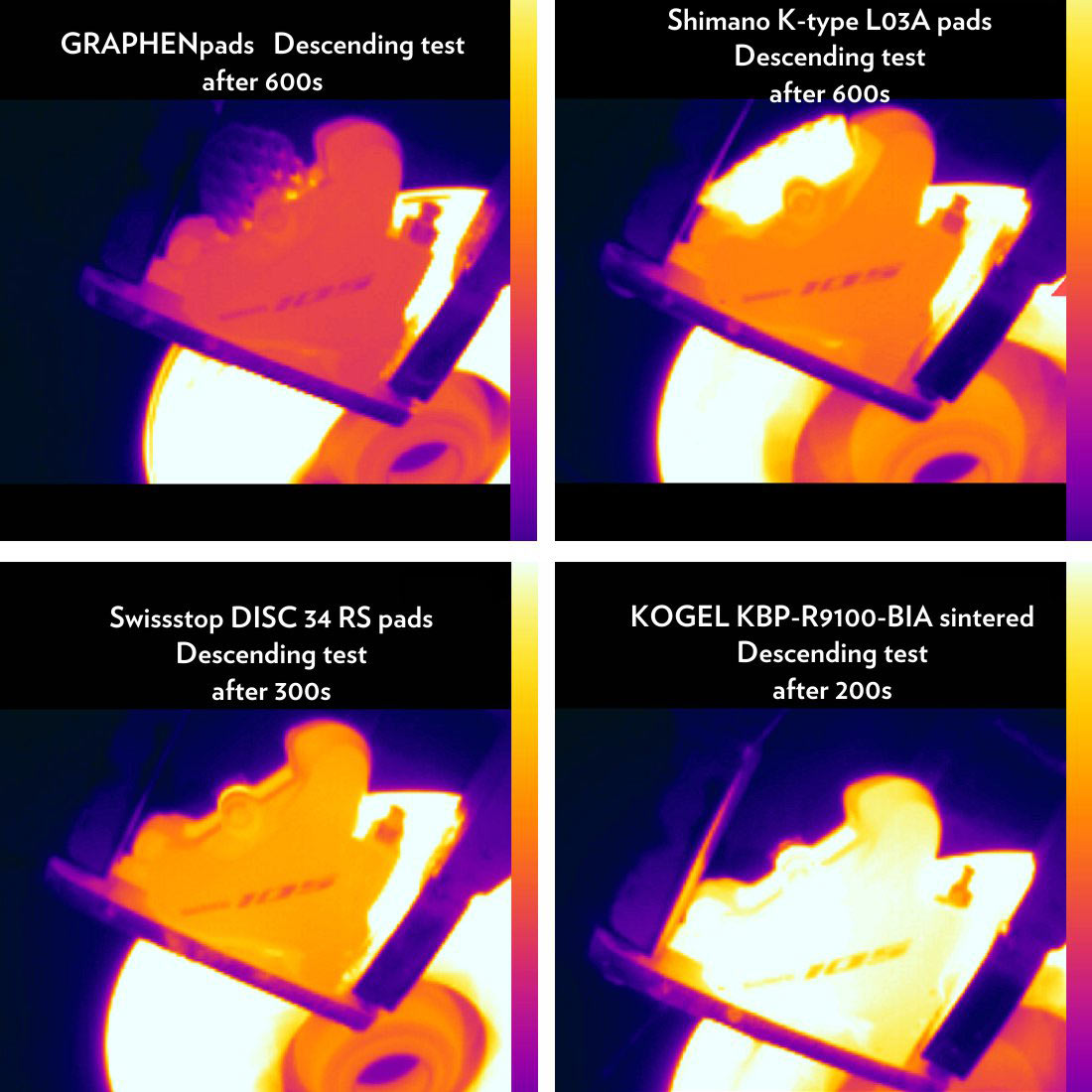

Descending test

In this testing sequence lasting 600s (10 min) and using a one-of-a-kind machine, we performed a simulation of a long descent on a road bike, with a constant force of 10N on the brake lever and slope angle of 12,5%. Velocity was 25km/h (15.5mph) with air blowing on the braking system at the same speed. Key parameters were recorded at 0.1s interval (6000 points per test). We used Dura-Ace Icetech rotors. This test helps us to understand how the brake system and friction material behaves during longer periods of braking and when the brake is subjected to fading.

In simple words we simulate a 100kg (220lbs) rider+bike gently dragging their brakes all the way down the descent. It is a typical behaviour for unexperienced riders when descending in alpine terrain.

We have compared GRAPHENpads to Shimano K-Type L03A (Dura-Ace), Swissstop Disc 34 RS and Kogel R9100 BIA pads. In every brake pad test we have used a new Dura-Ace rotor, new 105 caliper and new brake oil. Those control measures are important as once the caliper reaches over 450C, its seals sustain permanent damage and decomposition of braking fluid can occur.

When temperature of the caliper goes above 500C, aluminium core in the rotor starts to soften, causing permanent deformation of the braking surface. Each test was conducted following a standardised bedding-in process of the brake pad-rotor pair, with automated cycle of 100 braking events in dry, 30 in wet, 30 in dry conditions and various, pre-set intensities. Then we let the system to cool down to ambient temperature and dry out before main test.

Our machine tests and thermal imaging show that with GRAPHENpads® (Graph 1), it is possible to reduce disc pad and rotor temperature by up to 35% vs competitors and completely eliminate brake fading. It is also worth noting that friction coefficient remains very stable, which translates to very predictable and consistent braking performance.

From thermal imaging we can observe that GRAPHENpads were able to significantly reduce brake caliper temperature vs other brake pads, which translates to increased performance and prolonged life of caliper seals and braking fluid. (On images dark violet represents temperatures of around 27ºC and “white” represents over 400ºC)

Why cooling fins are the critical part of brake cooling ability

In order to explain how important the disc pad fins are to overall disc brake cooling abilities, first we need to understand what is the most important factor that helps the brake caliper, rotor, and pads to cool down. Air moving past all braking elements during the ride, plays this crucial role. Increasing the surface of disc pad backplate enables more exposure to wind hence improves cooling. The cooler the pads, rotor and caliper, the better the braking performance.

In the thermal images above, you can see GRAPHENpads tested with and without air blowing on the test setup. It is clear that without the wind, even the best brake pads start overheating very fast, showing how significant the role cooling fins play in overall temperature management and braking performance.

But graphene is used in super low friction lubricant…

In order to understand why graphene is such a good material for friction compound, one needs to understand how friction compound is made. Typical organic friction compound includes five classes of components: a fibrous material made from inorganic/organic/metallic fibers (like copper), a binder (like thermosetting polymer), a “filler” (various soft ceramic powders), one or more lubricants/friction modifiers (like graphite, copper), one or more abrasives (hard ceramic powders).

The binder, which is typically a phenolic resin that bonds all components together, has a very high friction coefficient, therefore it is necessary to add friction modifiers/lubricants to lower the friction coefficient and allow braking modulation. Copper is a great example of a material that not only acts as fibrous material but it is also a lubricant and conductor of heat to the backplate.

Graphene on the other hand is several times stronger than copper, conducts heat 3-6 times better, and its coefficient of friction is several orders of magnitude lower. By eliminating copper and finding the right balance of graphene and other components, we created one-of-a-kind friction material that delivers extraordinary performance.