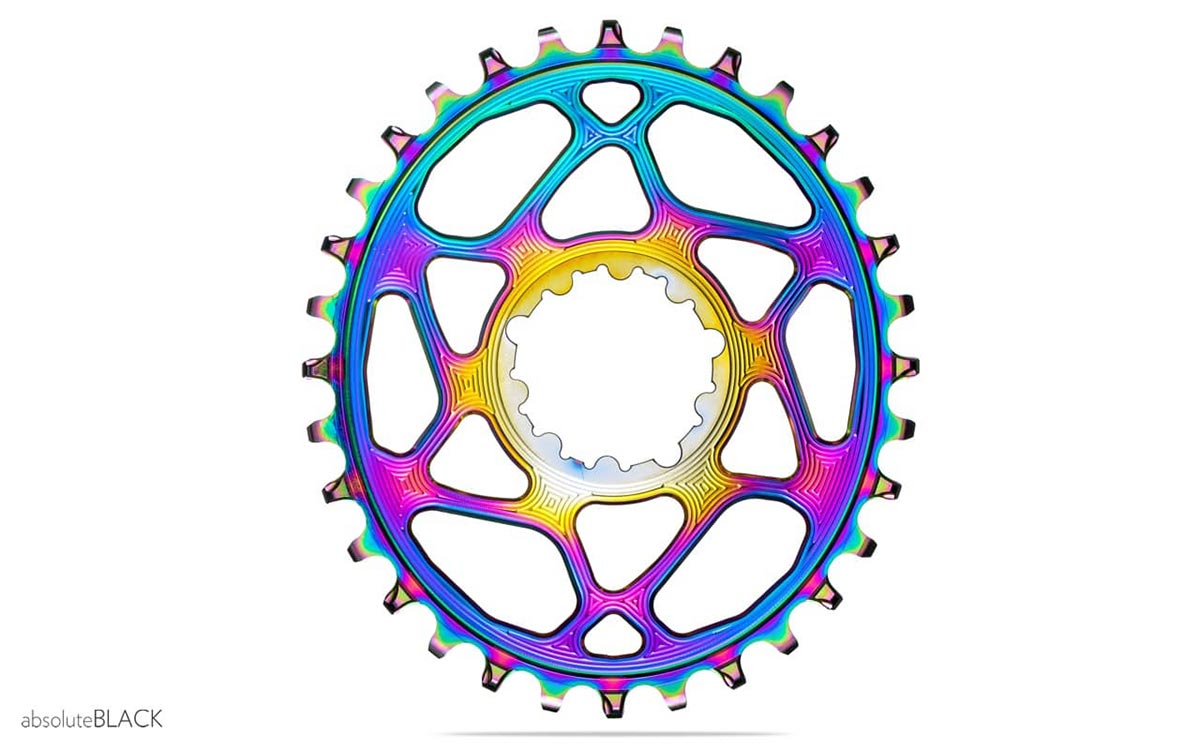

Joining the ever growing oil slick trend are absoluteBLACK, creators of some of the most scientifically-proven oval chainrings on the market. They begin by rolling out rainbow ovals for SRAM direct mount. If bling is your thing, now is not the time to back down. Check out the new AbsoluteBLACK PVD Rainbow ovals and consider whether that petrol-dipped colorway is worthy of the £109.99 price tag.

absoluteBLACK PVD Rainbow Chainring

If you’re unsure about the concept of an oval chainring and want to hear more, you should check out our Ask A Stupid Question feature on the very topic. absoluteBLACK, Rotor, Wolf Tooth and OneUp all chime in to discuss the benefits of oval chainrings over traditional round ones. You might learn something – we certainly did!

Only SRAM direct mount chainrings will be available with the PVD coating initially. You can get it for all sizes from 28T up to 36T. They are also Boost only, meaning they have a 3mm offset to fit most 148mm rear end spacing frames.

You will of course be wondering why the absoluteBLACK PVD Rainbow chainrings are £44 more expensive than the regular oval chainrings – which are themselves offered in black, titanium, gold, orange, red and purple colorways. The reason for the hefty price tag is the process required to create that oil-slick look.

PVD, or Physical Vapor Deposition, is a process by which the 7075 aluminium chainring is coated with titanium. It requires the use of a clean room. That’s not just a room that gets a good hoover and wiper down on a regular basis.

They come in different forms but, the cleanest of clean rooms, the ISO 1 clean room permits only 12 particles per cubic metre – and those particles are below 0.3μm in diameter. Basically, they are super tightly controlled environments. PVD has to take place in said clean rooms to stop particles interfering with the bonding of the titanium coating to the chainring.

It’s because of this that the AbsoluteBLACK PVD Rainbow is premium. The process costs a lot more than simpler anodizing. Also, not a single chainring will be the same as any other PVD coated one – the process turns out a different pattern every time.

There you go, bit of science for you. And these guys are all about their science. Check out their new GRAPHENlube wax-based, drip-on chain lube that they claim beats everything else currently on the market. A bold claim.