Jan-Willem van Soest has been building wheels with carbon rims since he was a junior racer, first for himself, then his trainer, and then more and more friends and others started asking for them. So, he started a business out of it, building wheels that were laterally stiffer, stronger and lighter than what those folks could find off the shelf. Five years after lacing his first wheel, he’s launching a unique, fully proprietary lightweight alloy rim.

“I was looking for an aerodynamic solution similar to carbon rims, but wanted to make it light,” van Soest told us via Skype. “We couldn’t find something under 550g that had the strength and stiffness we wanted, which in my mind was too heavy. So, we switched materials, and that let us get the rim weight under 500g with a 465-475g target weight.”

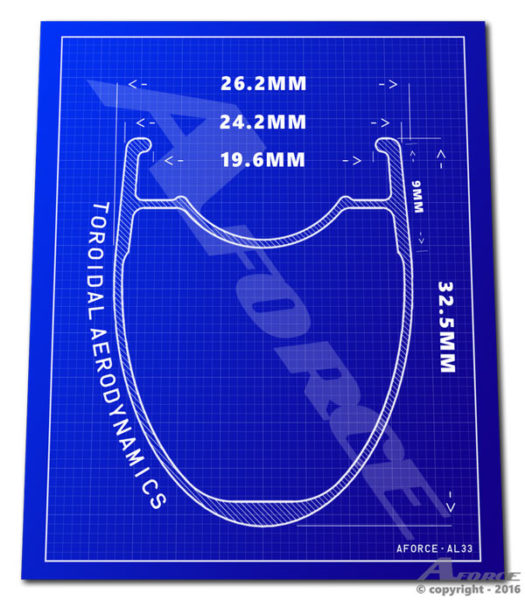

It has a toroidal shape, with dimensions very similar to several popular brand’s carbon rims, is tubeless ready outta the gate and is built into laterally stiff wheels thanks to some unique builds. Interested?

The wider rim design lets it match the lateral stiffness of carbon, but you retain the compliance of alloy so the ride and traction are potentially markedly improved over carbon. Van Soest says that becomes really evident in the high speed cornering found in cries and on the cobbles of Roubaix, where they were tested.

The clincher is optimized for tubeless, and they worked with Schwalbe to ensure good rim/tire compatibility.

OK, but really, why alloy? Price is one, but they were also able to make weight comparable while giving you better wet weather braking performance than carbon. And to boost that even further, they’ll offer a full ceramic coated rim to further improve wet braking, especially compared to carbon. The ceramic coating has three benefits. First, is the improved braking by increasing friction. Second, it adds durability since the coating should last for up to three years, after which you’re then braking on the regular aluminum. Third, it uses carbon-compatible brake pads, so if you’re switching back and forth between alloy “training” and carbon “racing” wheels, you won’t have to change brake pads. Although, as far as they’re concerned, you’d be just fine doing both on the AL33s.

The complete wheels will also be somewhat unique. They’re laced with a 2:1 pattern, similar to Campagnolo, but he found that just using 8:16 (non-drive:drive) spoke counts wasn’t enough to make it adequately stiff, so they used thicker 6.5g spokes on the non-drive side versus 4.5g spokes on the driveside. They also used an offset lacing pattern at the rim, letting the spoke angles slightly criss-cross each other. So, the driveside spokes hit the rim slightly on the non-drive side.

For complete wheels, they’ll use internal nipples to keep the aerodynamics as clean as possible. That, and they say those spokes and nipples test 25% stronger than external ones. For aftermarket rim-only sales, they’ll offer rims prepped for both internal and external nipples so the builder can choose. They’ll have 20, 24, 28 and 32 spoke counts for traditional lacing, and for 2:1 radial lacing they’ll offer 24 and 27 hole rims.

Trued to 0.05mm and spoke tension within a 5% maximum difference, which they say is very precise and takes 2-3 hours per set to build. So, even though internal nipples make adjustments more time consuming, they say their race testers have only had to fix or true a wheel if they’ve wrecked on it.

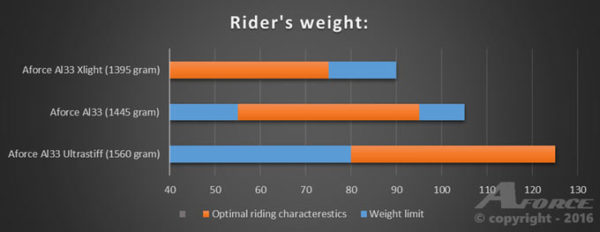

Rider weight limit is 100kg with a standard build. They’ll also offer heavy duty build that uses thicker spokes (and adds 80g to the wheelset) and bumps rider weight limit up to at least 125kg.

After initial prototyping in Holland, they found a rim manufacturing partner in Taiwan that was experienced working with 6069 alloy. That company provided input on the design, and they also had the best weld quality of any other vendor they looked at. Now, they’ve finalized the rim design and are ready to start production using a slightly modified, proprietary alloy called AF9X, so they’re turning to Kickstarter to fund the first run.

They’re looking to raise just shy of $20,000 and have several stretch goals that’ll allow them to do some extra things. They’ll offer it as plain ($135 retail) and with a ceramic coating ($160), but you can nab a pair at a deal in the crowdfunding campaign.