Seattle-based bicycle brand Albatross Bikes was founded by Will Hilgenberg, as a creative outlet for some of his ideas. These were concepts of bicycle frame designs that didn’t fall into the bicycle industry’s typical/traditional ideals of frame production.

There is always a demand for unique custom frames, and everybody would love to own that “one-off” frame made just for you. Hildenberg spent four years developing his designs to “produce a one-of-a-kind riding experience for their customers”.

Albatross Bikes follows a design philosophy that revolves around the following principles…

- Listen Closely –

“Every person deserves to be heard and we take it very seriously with a rigorous interview process that will help us know you and your needs. When we ship the bike we want to be confident that you will receive the bike that you have dreamed of owning”. - Think Laterally –

“With every product, we design to fit the needs of the customer above everything else. If we can’t make something off-the-shelf work, we will make it ourselves. Everything revolves around meeting the requirements of the customer”.

- Design Minimally –

“Bicycles are some of the simplest and most efficient vehicles in the world. We feel the need to respect this core aspect by ensuring we don’t add any superfluous design elements. If you find it on one of our bikes, it’s there for a reason“. - Test Everything –

“We provide only the highest quality product to suit your needs. To make that happen, we spend hundreds of hours testing parts and designs that we develop to ensure that you will never have an issue with your bike“.

Frame Ordering Process

There is an interview that takes place to get to know the customer and understand them and their riding style. Albatross will learn what the customer is looking for in their new frameset and says that “if you can dream it up, they can make it happen.

After the interview, they begin designing, analyzing, and iterating the customer’s unique frameset to make sure that everything “meets our standards and reflects your desired experience”.

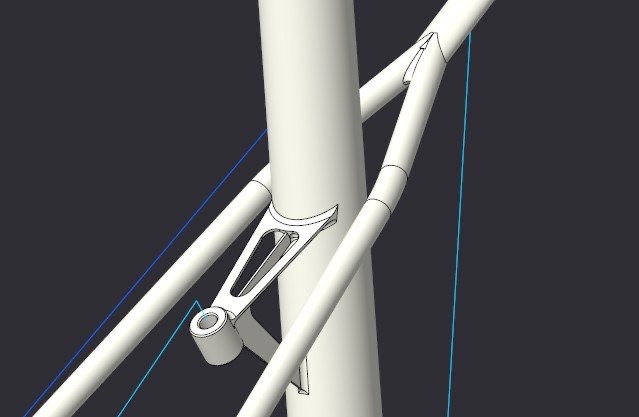

Once the frameset design has been approved, the building starts. Using brazing, machining, and even 3d printing, they say they have the “expertise to make even the most complex designs possible”.

Believing that designing a bike, means designing it as a “system” with every component and accessory a part of the experience. Albatross says that they will “work with your preference on bottle cage tension, brake lever placement, spares and tools used to build the components and accessories spec’d with your frameset”.

Lastly, using the hand-picked selection of parts, they assemble everything into a complete bicycle, “ensuring 100% compatibility with a professional level of finish work”.

Albatross is also offering UDH-compatible dropouts that work seamlessly on SRAM T-Type derailleurs and the SRAM UDH Derailleur Hanger.

Get started on building your own Albatross Bicycle here.

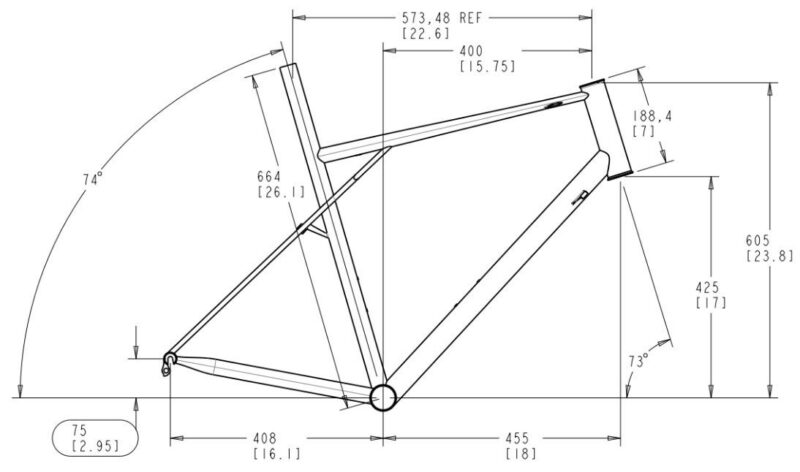

Road Bike Geometry

Road Frameset

Deposit: $500

Fully customizable

Material: Steel

MTB Frameset

Deposit: $500

Fully customizable

Material: Steel