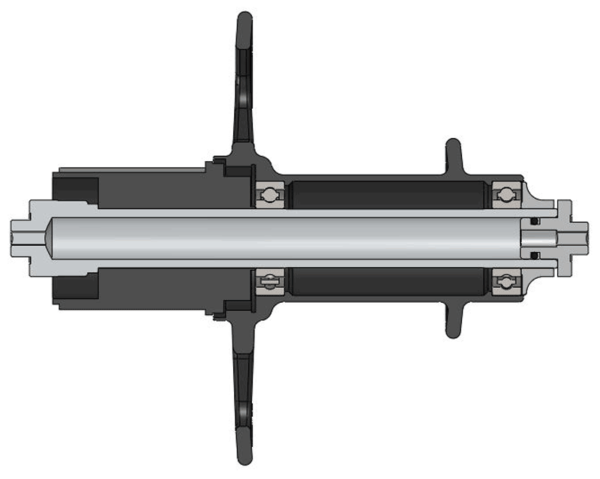

Alto Cycling has updated their hubs with new axles using a keyed assembly design that, along with improved bearing compatibility, makes their already ultra smooth hubs even better. The originals used NSK angular contact radial bearings, but then switched Enduro angular contact bearings, but the design still required some clamp force from the skewers to put the ideal amount of load on the bearings. So while they worked very well, there was room for user error depending on how tightly someone clamped the wheels into the frame. This new design switches to radial bearings and new flanged axles and end caps to remove all axial load from the bearings to they can spin freer than ever.

“The whole reason for the design change was two-fold,” said co-founder Bobby Sweeting. “We had requests for ceramic bearings, and we wanted to use NSK bearings, which (now) only offer radial bearings. Our previous design angular contact bearings, so this redesign allowed us to maximize the lifespan and offer higher quality Japanese steel bearings. And now we can offer Kogel ceramic bearings as an upgrade. And both bearings have better seals, too.”

Sweeting said they couldn’t find any angular contact ceramic bearings that they were happy with. They weren’t happy with the seals, or the pricing, or availability for the sizes they need. So the best solution was a hub redesign that allowed them a better selection of bearings.

“When we started looking at the design, we found that using a plug system worked really well,” Sweeting said. “We looked at jam nut designs and others, but we wanted a simple design and one that had no axial or side loading on the bearing. The downside with other brands that used a plug system for the end caps was that many have low tolerances that were either too tight and difficult to remove for wheel service, or they were too loose and could flop around or fall out during wheel changes.”

“When we started looking at the design, we found that using a plug system worked really well,” Sweeting said. “We looked at jam nut designs and others, but we wanted a simple design and one that had no axial or side loading on the bearing. The downside with other brands that used a plug system for the end caps was that many have low tolerances that were either too tight and difficult to remove for wheel service, or they were too loose and could flop around or fall out during wheel changes.”

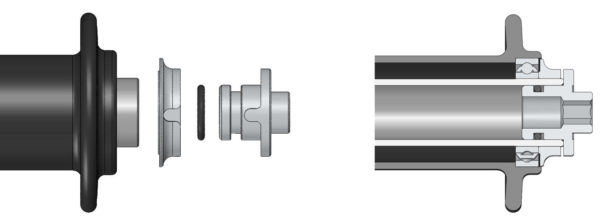

They came up with a patent pending design that uses a male key way and adjuster ring to thread the axle together. Like before, a flanged design prevents the axle and end caps from being overtightened. They stop right at the edge of the bearing, so it’s completely sealed, but there’s no side load placed on the bearings.

The O-ring uses a 2mm 90-durometer rubber that’s very stiff, which keeps it firmly inside the axle. You hand thread the adjuster ring onto the axle (it threads onto the outside surface), then insert the end cap in so that the key/notch lineup and use two 5mm allen wrenches to snug things up. There’s no need to over tighten. To remove the end cap, you simply use the allen wrenches to unthread the axle, which pushes the end cap out. Or vice versa if you ever do develop any play. The driveside end cap is part of the one-piece axle.

They use ABEC 7, which is an extremely high precision rating for bearings. These changes are for the quick release, rim brake wheels only. The disc brake wheels will continue to use the original angular contact bearing design. That’s because this new design wouldn’t fit all of the different thru axle options, but it is something they’re looking at offering for disc brakes and thru axles in the future.

The hub shells are unchanged, so you could upgrade to the new axles if you want to upgrade the bearings. Just contact Alto Cycling directly through their website if you want that. Upgrade pricing $225 with the stainless steel NSK bearings. Complete wheelsets carry over the same price as before, there’s no increase with the new axle system, and those are available through your local bike shop. Kogel ceramic bearing upgrade is $200.

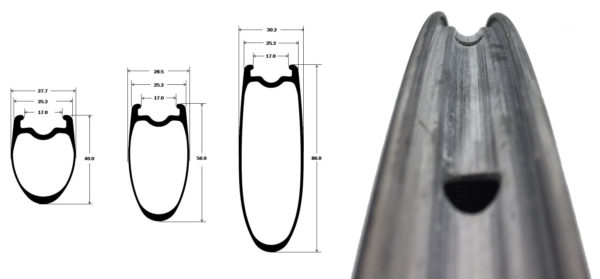

For both rim and disc brakes, all of their carbon rims are now tubeless compatible. The change comes after more than eight months of testing to fix two main issues they found with other carbon clinchers. One, it needed to be easy to mount a tire. They admit it’s a tiny bit harder to mount than a non-tubeless, but it shouldn’t be anything the average rider can’t manage at home.

The second was they wanted a tight seal to reduce the amount of air that slowly leaks out over time. The goal was to have tires that remained at about the desired pressure for at least four days after you pump them up, so you didn’t have to check and inflate before each ride. They accomplished this by fine tuning the rim profile. The new internal shape aids tire seating during initial setup, but then holds the bead tight enough to create a very solid seal.

Both the rim and disc brake versions use the same profiles, but the disc brake rims are about 40g lighter because they lack the basalt (stone, basically) brake track and extra material needed for rim braking. The disc models are available in the 40mm and 56mm depths only. For the most part, you can only get them as complete wheels, but they do sell hubs and rims separately to a few select custom builders in the U.S.