If you’ve been visiting the site for the past couple of years or longer, then the name Apogee Bikes might sound familiar to you. We initially reported on the brand’s launch announcement and unique frame design a couple of years ago. Just a few days later, we awarded the Apogee a MADE Show Best MTB in Show Award. It was a rideable prototype at the time, a proof-of-concept that turned heads and certainly generated some buzz for the fledgling brand.

Using that prototype, the Apogee team continued to fine-tune the design, making incremental changes to the Free-Float Module and steel DuoFrame. Ultimately, they ended up with the current iteration of the bike, which they showed at MADE in 2024 and began selling late last year. The Apogee One, as it is now known, is 100% designed, hand-welded, machined, and assembled in the USA and is unlike anything else I’ve ever seen or ridden.

When I was reading our MADE Show coverage back in 2023, I didn’t realize it at the time, but one of the co-founders of Apogee Bikes is an acquaintance of mine. Collin Huston and I initially became “Strava friends” due to our shared affinity for riding our bikes uphill quickly on our local trails. Eventually, I came to realize that he was one of the founders of Apogee, but until just recently, we never connected for a test ride or a shop tour. A couple of weeks ago, I finally met up with Collin for a tour of his machine shop in South Lake Tahoe and a test ride on the super unique Apogee One.

About Apogee Bikes

Collin Huston and his friend Will Hilgenberg founded Apogee Bikes in 2022. Having worked previously with brands like Ibis, Specialized, Bell/Giro, and Praxis, Hilgenberg brought years of cycling industry design experience to the table. Collin, the owner of Huston Precision — a precision machine shop in South Lake Tahoe — brought his machining expertise, a shop full of equipment, and his love of riding. Together, the pair set out to design and produce a bike that they and others would get excited about.

The Apogee team has since grown slightly to include a few more folks excited about making quality bikes with an outside-the-box design and construction. But what started as a passion project mostly remains a passion project. Believe it or not, boutique bike brands aren’t getting rich off of bike sales. For the Apogee crew, it is still largely a side project — a super awesome side project. But the business is scalable, and until they hit the big time, they are committed to putting out an extremely polished and high-quality finished product that’s unique in the market.

The Apogee One

What the Apogee team came up with is most definitely unique, eye-catching, and buzz-worthy. The bike is built around the Free Float Module (FFM), a machined aluminum suspension linkage paired with a handmade steel “DuoFrame” making up the front and rear triangles. The FFM may look somewhat complicated, but it is essentially a linkage-driven single-pivot design with the shock “floating” between two rocker arms. But they designed the FFM to do more than just look cool.

First, the majority of the pieces of the FFM are machined in Huston’s precision machine shop, with a few other custom parts and hardware coming from select sources. When assembled, the FFM essentially decouples the suspension and all of its moving parts from the rest of the frame, ensuring a stiff and precise interface compared to the more compliant steel frame that’s attached to it. This keeps the shock and pivots aligned for smooth travel and longevity of the Enduro MAX bearings, while still enjoying the ride feel afforded by the steel frame.

Second, the FFM’s position on the bike gets the weight of the shock and linkage as close to the ground as possible for a low center of gravity. Third, the parts of the FFM can be swapped out to achieve different travel lengths or to customize its performance to suit varying needs and preferences. For example, it can be set up to get 120-ish mm of rear wheel travel, although 140 mm seems to be the sweet spot.

The steel DuoFrame is welded by hand by Rat King Cycles in Seattle, Washington, to the exacting standards needed for alignment with the Free-Float Module. With the stiff FFM handling the suspension, the steel front and rear triangles can be tuned independently to provide desired ride characteristics. Steel is already a relatively forgiving frame material, but the team purposely designed the rear end with thin tubing and a little extra flex for a smooth ride. It also has the distinctive tapered/flattened top tube along with some decorative and functional reinforcements at the head tube and seat tube junctions.

The Module/suspension linkage is the same across all five frame sizes, with the size of the front triangle being the primary differentiator. The rear triangles are the same across the board, but the machined dropouts can be swapped out for a mixed wheel setup or to adjust the chainstay length. Collin tells me that there is a range of options available to people on the “off-menu program,” and they are happy to work with buyers to customize fit and setup within reason.

The frame is also “backed by ISO 4210 testing for Falling Mass, Falling Frame, Horizontal Fatigue, Vertical Fatigue, BB Vertical Load, Tire Contact Fatigue, and Pedal Fatigue.” On top of that, the steel frame and FFM are covered by a 3-year warranty covering defects in materials and workmanship.

Geometry

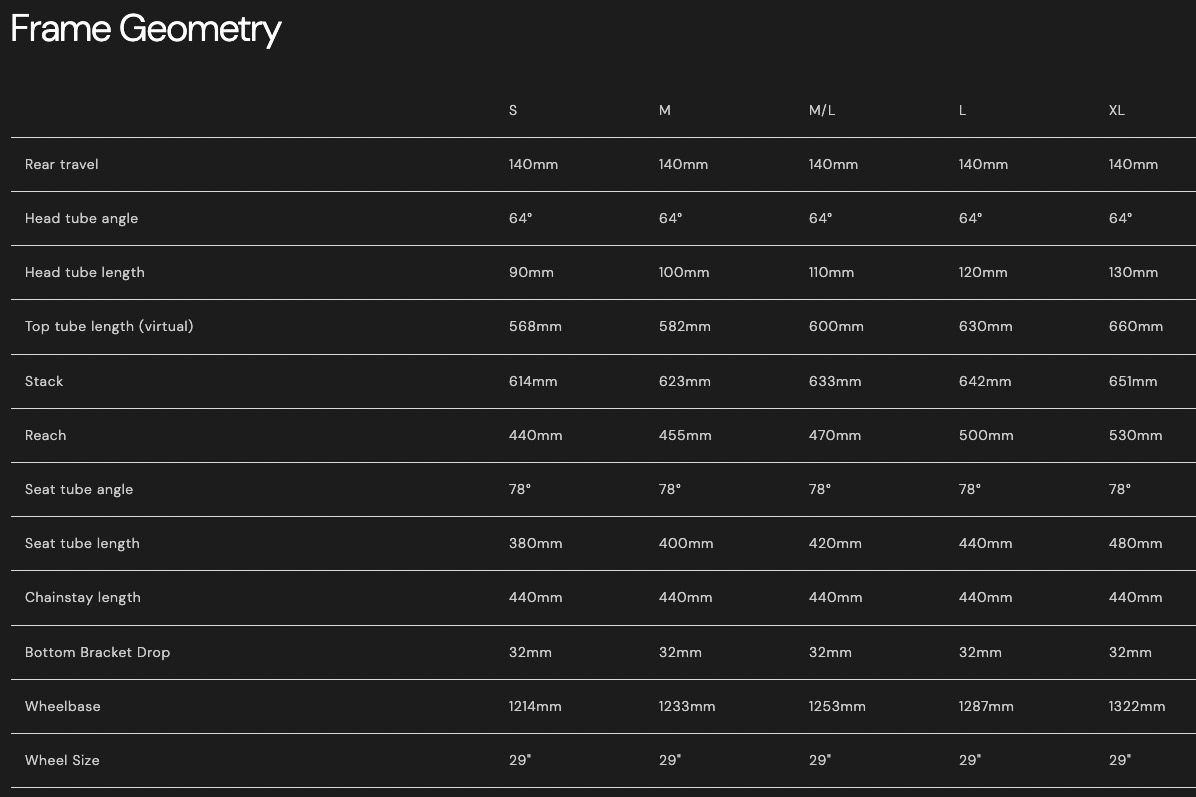

With 140 mm of rear travel paired with a 160 mm fork, the Apogee One falls pretty squarely in the do-it-all trail bike travel bracket. With a geometry that includes a 64-degree head tube angle, high stack, and fairly long reach and wheelbase measurements, however, it falls more toward the aggressive side of the trail riding spectrum. As mentioned above, it comes in five sizes and is intended to fit riders between 4’11” and 6’6”. Check out the chart below for all the details.

Apogee One Build Options

The Apogee One is sold as a frame only or as a complete build. Either way, buyers can choose between five frame sizes and three frame colors — Manzanita Root, Potter’s Clay, and Dark Beach Stone Blue. The frame-only includes a Wolf Tooth headset, seatpost clamp, rear axle, and a SRAM UDH and goes for $4,295.

They offer one complete build for $6,995, or buyers can select the rear shock, fork, build kit, and wheels from the options listed in the website’s configurator. This allows you to upgrade from the stock build and pick the parts you want right out of the gate.

That said, the stock build kit is something I’d have no qualms about riding. It’s got a Fox 36 Performance fork, Cane Creek Coil IL shock, a full SLX kit (drivetrain and 4-piston brakes), and a nicely appointed cockpit. It’s safe to assume, however, that anyone buying a unique bike like the Apogee One has a pretty good idea of the parts they want to put on there, too.

The Apogee Machine Shop

In addition to being one of Apogee’s founders and Head of Operations, Collin owns and operates Huston Precision — a busy machine shop near his home in South Lake Tahoe, CA. I visited him a few weeks back to see where the magic happens and go for a test ride on the Apogee One.

I wasn’t quite sure what to expect at the shop, but I was surprised to see how big his operation is. I didn’t realize the scale of the business until I saw it in person. The large shop space has multiple 5-axis CNC machines, precision scanning equipment, and a variety of other machines. Turns out he keeps quite busy making super precise parts for all kinds of things — including robotics. He showed me a tray of robot finger parts along with a bunch of impossibly small aluminum washers. One of his employees was in another room scanning other parts to be machined another day.

The Huston Precision business is how and why Collin owns and has access to all of this fancy, high-end machining equipment to make the parts for the Apogee One’s Free Float Module. It was also instrumental in the earlier prototyping and testing phases of the bike’s development, as he could quickly and easily make new parts, swap them out, and head out for a test ride.

Now, with the Apogee One in production, the FFM parts are produced in batches and assembled into complete modules awaiting purchase. When a bike is ordered, the frame is welded, painted, and assembled with the FFM into a frame-only or complete build.

How Does it Ride?

After checking out the shop for a while and getting the whole rundown, Collin set me up on his personal bike, and we went out for a test ride. He also let me hang onto it for a bit, so I could make some adjustments, get some more miles, and ride a variety of trails.

This article is long enough already, so I’ll check back with my impressions of the Apogee One very soon. In the meantime, you can learn more about the bike and the brand at: