After a 5th anniversary sneak peek in late January, the alloy Atherton S170 enduro bike is official. Subtractive vs. Additive. Now in aluminum it is just as affordable as we had hoped. But even more interesting that I expected. Not just another alloy mountain bike, the aluminum Atherton features similar lugged construction like the carbon & ti bikes, but reoptimized to take advantage on CNC-machining tech. Machined lugs, custom drawn tubes bonded-in, plus an all-new machined rear triangle with 170mm of DW-link suspension.

Atherton Bikes S170 affordable alloy enduro bike

With complete bike prices for even less than the cost of a bare carbon & 3D-printed titanium frameset, this is your most affordable way to get on an Atherton Bike. And don’t feel like you are skimping on quality with the S170, Atherton Bikes are calling this their “awesome and super-tough” new bike, their “everyday… chuck it in the van and go” bike.

Breaking down the new overall naming conventions. S-series bikes are Subtractive, i.e. starting with a block of aluminum and machining away the excess to achieve its final form. A-series are Additive, 3D-printing or additive manufacturing adding layer upon layer of ti material to create the final lugs, and laying up layers of carbon to create a final tube shape.

So, why alloy?

“We had to be as excited to ride this bike as our A170 and that’s a huge ask… The DW4 comes with the top-notch performance that our customers demand, and frame compliance and geometry are direct descendants of the A170 for that playful ride character that we love.”

– Gee Atherton

The Atherton Bikes team set out in aluminum to “create a hard-hitting, big-mountain enduro bike that mirrors the lug and tube construction of the brand’s world-beating Additive (A) series“. The goal being to create a more affordable bike, built to survive the everyday beating of regular riders.

“From the day the brand launched in 2019 the team have set out their ambitions for a more affordable bike that would allow them to support grassroots riders like the people that they ride with every weekend.“

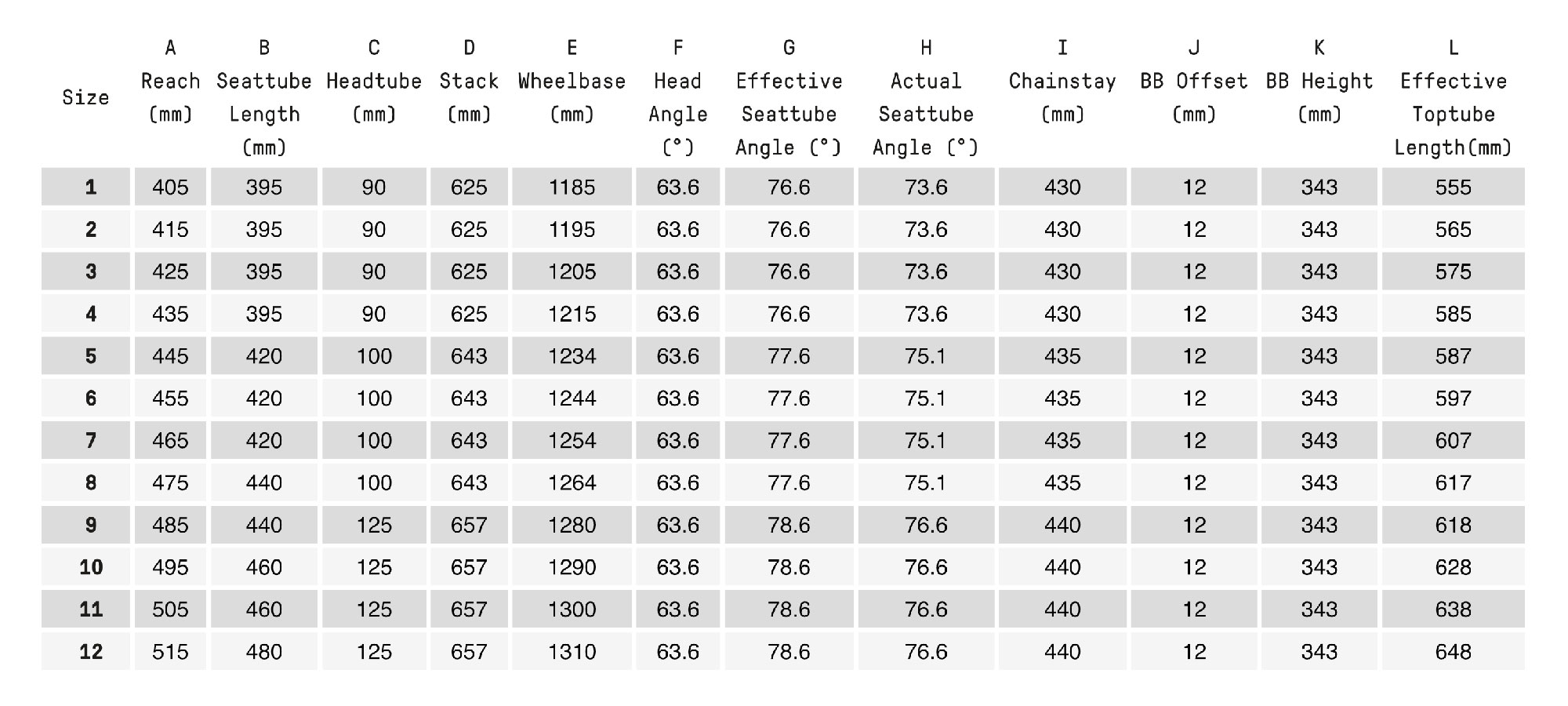

And they did that by sticking to the same lug & tube construction concept, even in alloy. Matched to lots of CNC machining. That helped make a super strong bike, and still made it easy to offer a huge 12-size range to make sure every rider gets their perfect fit.

With super slack, progressive geometry refined on the AM.170.

“I’ve put in a lot of hours on this bike and can say from experience that it’ll take everything you can throw at it. It’s made from a different material but we were determined that it would feel like an Atherton. We will only ever produce bikes that we’re proud to put our name on the downtube”

– Dan Atherton

Tech Details

The new alloy Atherton S170 is a mixed wheel size mullet bike with 170mm of rear 27.5″ wheel travel paired to 180mm 29″ forks. They say suspension is slightly simplified with a short-link DW4 Dave Weagle design (vs. the DW6 of the A170, née AM.170). The difference means the rear triangle can be simply machined in 1-piece per side, mated to a short lower link & rocker link both on the seattube.

Atherton makes the S170 frame from 7075 alloy billet machined into lugs, links, and the rear triangle side. Then, custom-drawn 7075 aluminum tubes get bonded into the double lap shear joints machined into the end of the lugs. The subtractive manufacturing process is even being patented – UK Patent Application Number GB2400886.4.

Atherton describes that bonding instead of welding lets them take advantage of the 70% higher fatigue performance and 70% higher ultimate tensile strength of 7075 vs. the 6061 alloy typically used in aluminum mountain bikes. And seeing as how they already dialed in that super strong double lap joint on their A-series bikes, durability seems to not be a worry.

“There’s nothing radical in any of the separate elements of our new manufacturing process but we’ve brought them together in a combination that is genuinely unique. And we’ve used established technologies but taken some innovative approaches only made possible by close collaboration with our technical partners. We knew we’d only discover our limits through the most rigorous testing, luckily we have the perfect testing location and the perfect testing crew…”

– Rob Gow, Atherton Bikes Head Designer

Atherton S170 alloy enduro bike – Pricing, options & availability

Pricing for the new alloy Atherton S.170 starts at £4800 / $5119 / 4679€ for a complete bike. Compare that to £4500 for an A170 carbon & ti frameset alone.

The new alloy S.170 frame sells for just £2800 with a Fox DHX2 coil shock.

The all-new S170 has passed EFBE Tri Test Cat 4 (Enduro) AND Cat 5 (Downhill) meaning that Atherton can offer a lifetime first-owner guarantee wherever you ride.

The new UK-made alloy bikes are officially on sale starting today direct from the Atherton Bikes website. But the bike maker expects they will be available in limited numbers for the time-being, while they “scale-up their production capacity” at their newly-built headquarters in Machynlleth, Wales.

Also, this is said to be only the first bike in the new S-series. So we expect to see more affordable versions of Atherton Bikes’ shorter and longer travel mountain bikes as they ramp up their in-house and partner manufacturing processes.

“Producing affordable bikes in the UK clearly has its challenges, especially for the design and production teams who were pushed to the edge on this one! But regardless of the drop-in unit price there will be no compromise on Quality Control. From the beginning of our brand this more affordable bike has been the dream, delivered with the same uncompromising attention to detail of the A-Series. Although we’ll outsource some of the manufacturing processes, we will still bond all of the frames in-house in Machynlleth. Fans of our A-Series shouldn’t worry, it’s not going anywhere, in fact we’re working hard to offer even more customisation options.”

– Dan Brown, Atherton Bikes CEO