Gary Ewing wasn’t entirely sure what he was trying to achieve when he began working on his “Kind of like a Rearward Pivot URT” (KOLARP) suspension design. It seems the whole process has been more of an exploration and learning opportunity from the outset, rather than a specific project at the end of which he had a goal in mind. Nevertheless, having only embarked upon the Auckland Cycle Works journey at the beginning of the pandemic, he turned up at Bespoked 2022 with not one, but two prototypes, one of which cost him around £30,000 to make! The Marra and The Reiver are the fruits of his labor, and we suspect there’s a lot more on its way.

We had a long chat with Gary at the show, learning more about where the ideas for Auckland Cycle Works came from, and his plans for the brand’s future.

Gary Ewing’s Auckland Cycle Works

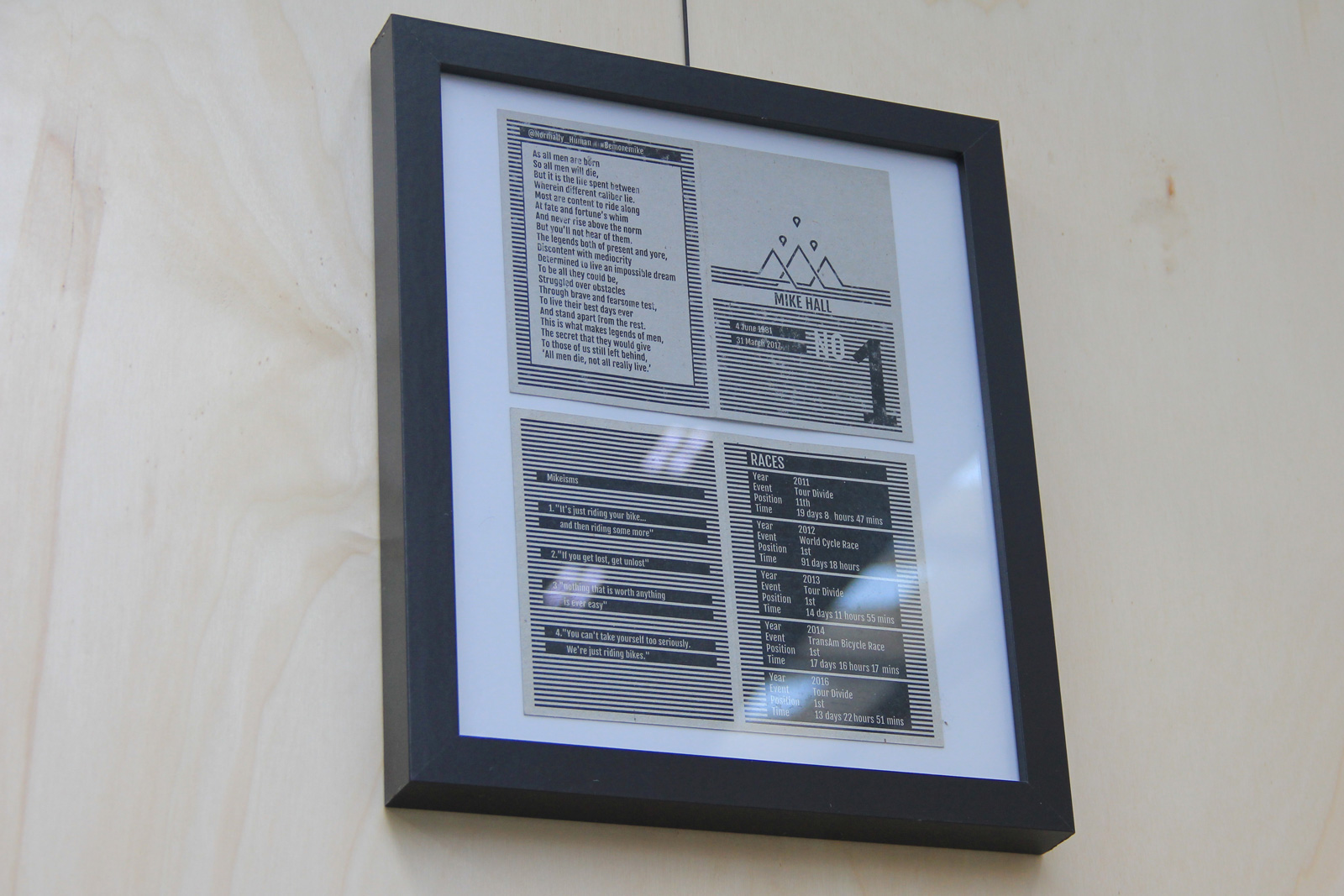

Gary Ewing is a bicycle mechanic and bike shop owner from Bishop Auckland, England, who has taken it upon himself to design some fascinating new suspension linkages without the use of any software. He has relied principally upon his own vision and ability to model his linkage designs using little more than a pencil, a piece of paper, and whole bunch of Lego. It all started 20 years ago with Gary’s friend, Mike Hall.

Mike Hall was an ultra endurance cyclist that was tragically killed four years ago while racing in the Pacific Wheel Race across Australia. Gary was a long-time friend of Mike, and puts much of the inspiration for Auckland Cycle Works down to his riding companion. Twenty years ago, Gary recalls quizzing Mike about the bike he designed for his A-Level project; all he got out of him was that it was “Kind of like a Rearward Pivot URT” (hence KOLARP).

It was a “Rearward Pivot” because the rear axle was pivoting about a point in space that was within the circumference of the rear wheel. And, it also resembled a URT (Unified Rear Triangle) because the bottom bracket was actually located on the swing arm (see the Paradox prototype for a more recent example of that). Seems crazy nowadays, I know.

Two and a half years ago, Gary was looking for challenges outside of running his own bike shop. He needed a side project, and re-creating and developing his late riding buddy’s suspension linkage was the idea that captivated him most.

Gary tells us that, in the case of some URTs, when you stamp on the pedals, the suspension compresses and basically folds the bike in half. To gain first-hand experience of how a URT suspension platform performs, he decided to make a few for himself, but his differed in that they actually had a rearward axle path. He wondered if that would overcome the drawbacks of traditional URTs.

The initial prototype was terrible, apparently, but not terrible for the reasons he was expecting it to be. He expected it to pedal terribly for the aforementioned reason, and just feel very strange altogether thanks to the bottom bracket’s position moving in relation to the saddle.

Neither of these things actually happened, however. Gary says that it climbed very well in easy gears, but as soon as you shifted into harder gears, it actually did become awful. It was a very good technical climber, but performed poorly under power in a sprint scenario.

When freewheeling down smooth singletrack, Gary says it was rapid, something he puts down to the rearward axle path. That bike had the linkages in the same position as those seen on the Auckland Cycle Works Marra, but the bottom bracket was on the swingarm. It was that latter aspect of the design that “had to die” in Gary’s words.

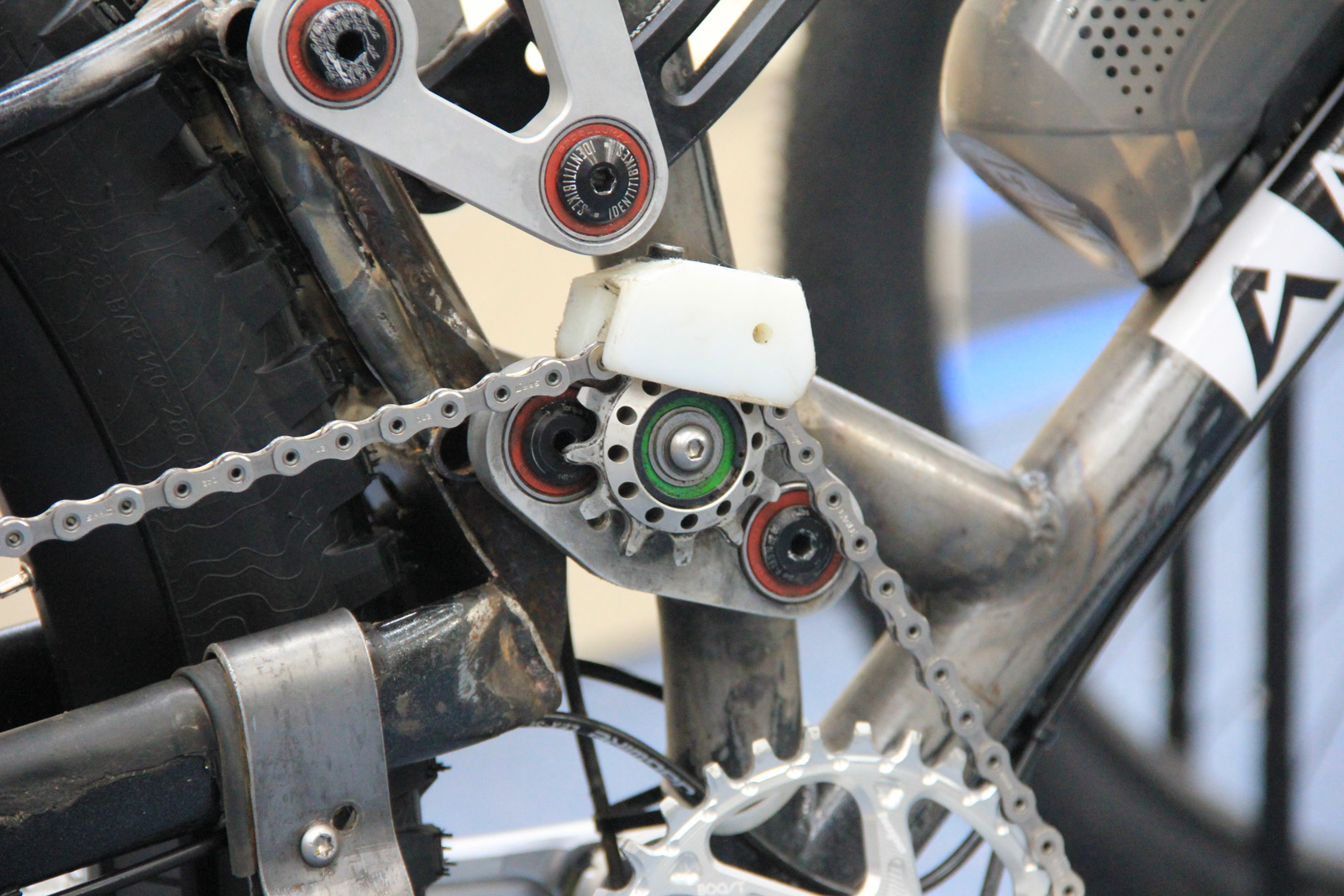

Shortly after that, Gary had a “sit up in bed moment”, where he realized exactly what the prototype needed to become the bike it is today. That idea was to use a high-idler, with the idler on the lower link positioned above the chainring. He drew it out on a piece of paper, went to sleep, then when he woke up he went straight to work on prototyping the whole thing in Lego (more on that later).

As you can see in the above video, the two links co-rotate in an anti-clockwise direction as the suspension compresses. Gary says the Marra’s rearward pivot exaggerates the curvature of the rear axle path such that, at east for the first half of the travel, you get a very diagonal rearward axle path, followed by a more vertical axle path in the latter half of the travel. He hasn’t measured it exactly, but reckons the rear-center length increases by somewhere between 45mm and 60mm during suspension compression.

We asked Gary why he thinks this particular linkage had not been tried before, or at least made it onto a production bike. “Cos computers”, was the short answer he gave.

“I always felt that it was worth doing something this bonkers. People design things on computers according to values and numbers. For example, braking anti-rise has to be within this range, pedaling anti-squat has to be within this range, movement of this thing has to be within this range. It just limits creativity. How are you ever going to design something that is different if you’re only ever sticking to those parameters?” – Gary Ewing.

Auckland Cycle Works Marra

Gary is very happy with the Auckland Cycle Works Marra in its current configuration. There are of course a number of things that need refined, but he says it is not so far off what he would consider the finished Marra. Here are some ball park numbers to mull over:

- Bike: Auckland Cycle Works Marra (prototype)

- Wheel Size: 29″ F, 27.5″ R

- Fork Travel: 170mm (will take a 200mm)

- Rear Wheel Travel: Adjustable between 155-180mm

- Head Angle: 64°

- Rear-center length: 415mm (unloaded)

- Reach: 475mm (Large)

- BB Drop from rear Axle: 5mm (but this will be adjustable)

Gary did experiment with various swingarm lengths, simply by welding an extra tube onto the front of the swingarm housing holes for the pivot hardware. In the short position he describes it as “amazingly playful and agile”. In the longer chainstay position, as seen on the bike ridden at the British Champs Enduro, the climbing performance is improved, but the bike does lose some of its playfulness.

The plan is to keep the chainstay length adjustment feature in any production version of the bike, but this will be more traditionally located at the dropouts.

Gary experimented with six different positions for the idler. He imagined that one position would be best for climbing, and another position would be better for descending. He says he never expected the same position to be the best for both climbing and descending.

He also believes the Marra will make for an excellent eBike. “When you point it uphill the suspension doesn’t compress. With a long travel bike, when you point it uphill, the rear suspension sags more because your weight has gone back. This resists that tendency”. Gary puts that down to the 45° axle path, though he isn’t exactly sure why.

“My next step is to design the suspension linkages as a module, that can then be given to someone else to weld into a complete steel frame. Bikes might be ready in very limited numbers for spring/summer 2023”.

Auckland Cycle Works Reiver

The Marra wasn’t the only Auckland Cycle Works prototype on display at Bespoked 2022. Feast your eyes on the Reiver, a much flashier prototype made from a carbon tubeset with 3D printed aluminum lugs. It is an XC/Marathon bike that cost Gary somewhere in the region of £30,000 to make. That’s not just the cost of the materials; it includes the R&D time required, too. This one was so fresh that the joints had not yet set, so by the time Gary showed it at Bespoked, he’d not actually ridden it yet.

The Reiver too began its development as a Lego model. Note the anti-clockwise co-rotation of the two links that connect the rear triangle to the front triangle. Here, the BB is positioned on the lower link itself. As the suspension compresses and the rear-center extends, the bottom bracket moves downward.

After writing the patent for the Marra, Gary wondered how another company might seek to copy his design, but in a way that circumvented his patent. He set about taking on that challenge himself, and the Reiver was the result. He realized that, instead of having the high-idler on the lower link, he’d need to put the BB on the lower link.

The Reiver prototype is ultra-adjustable. The lower link houses the BB offset of center, and it can be oriented to give the BB four possible positions. It can be flipped back-to-front and sideways to position the BB closer to or further away from the pivot on the front triangle, or higher or lower relative to the swingarm.

You will also notice there is a flip-chip located at the pivot where the lower link meets the front triangle. So, actually, there are 8 different configurations in which Gary needs to test his bike! That’s before you even consider potential use of offset bushings and tokens, etc. In its current configuration, it has 120mm of rear wheel travel, and is paired with a 120mm travel fork.

Gary hoped the Reiver’s suspension would be super stiff when the rider is sat down pedaling, but more supple when you stand up. Since arriving home from Bespoked, he’s managed two test rides aboard the Reiver. Here’s what he has to say:

“When seated, the Reiver climbs like a short-travel XC race bike. When standing, it rides like a 150mm trail bike. Slack geo makes it safe to attack the downhills, but isn’t an impediment anywhere else”.

We’ll be staying in touch with Gary over the coming months and years to follow the journey of Auckland Cycle Works. You can get in touch with Gary to learn more about the brand through his bike shop, Inspiral Cycles.