BRIDGE Bike Works believes that a threaded bottom bracket is the best solution to avoid creaking and problems with your BB. But they also want to avoid having to bond in an additional aluminum shell into a carbon frame. Not only does that process add weight, but it still provides a chance for misalignment and potential separation of the shell down the road.

So then what’s the answer? Apparently, it’s to mold the threads directly into the bottom bracket shell itself.

Today, BRIDGE announced a patent-pending integrally threaded carbon BB shell to answer that question. While the shell is based on T47-BB86, the say that they can apply the technology to any threads on the bike, including other BB sizes.

Is Carbon Durable Enough for Threads?

It’s bound to be a question – is carbon durable enough to serve in this function? To that, BRIDGE says that they have engineered the entire process from raw carbon, to molding, to curing to ensure that the final design will be up to the task. On top of that, when everything is done, the threads are treated with Cerakote. This abrasion-resistant ceramic coating should be capable of protecting the threads for repeated bottom bracket replacements if you need.

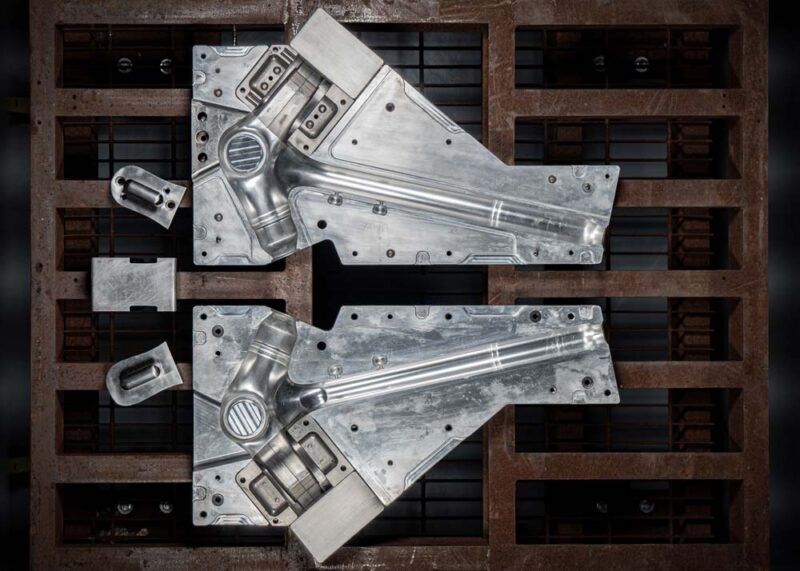

We’ll get more info on the process at Sea Otter, but BRIDGE is at least showing the BB mold and the threaded BB inserts that help create the carbon threads. More soon.