Over the years Campagnolo’s carbon Bora wheel line has been possibly the winningest family of wheels in the pro peloton. Recent updates have widened their rims, shed weight, added disc brakes, and even improved rim braking. But aerodynamic optimization had stagnated… until now.

Campagnolo Bora WTO carbon tubeless aero wheels

Campagnolo continues to focus on the top-level of road racing for the bulk of their product development. And that’s not just relegated to the first 12-speed road bike drivetrain. Campy’s wheels are some of the fastest rolling and most durable to be found in pro racing.

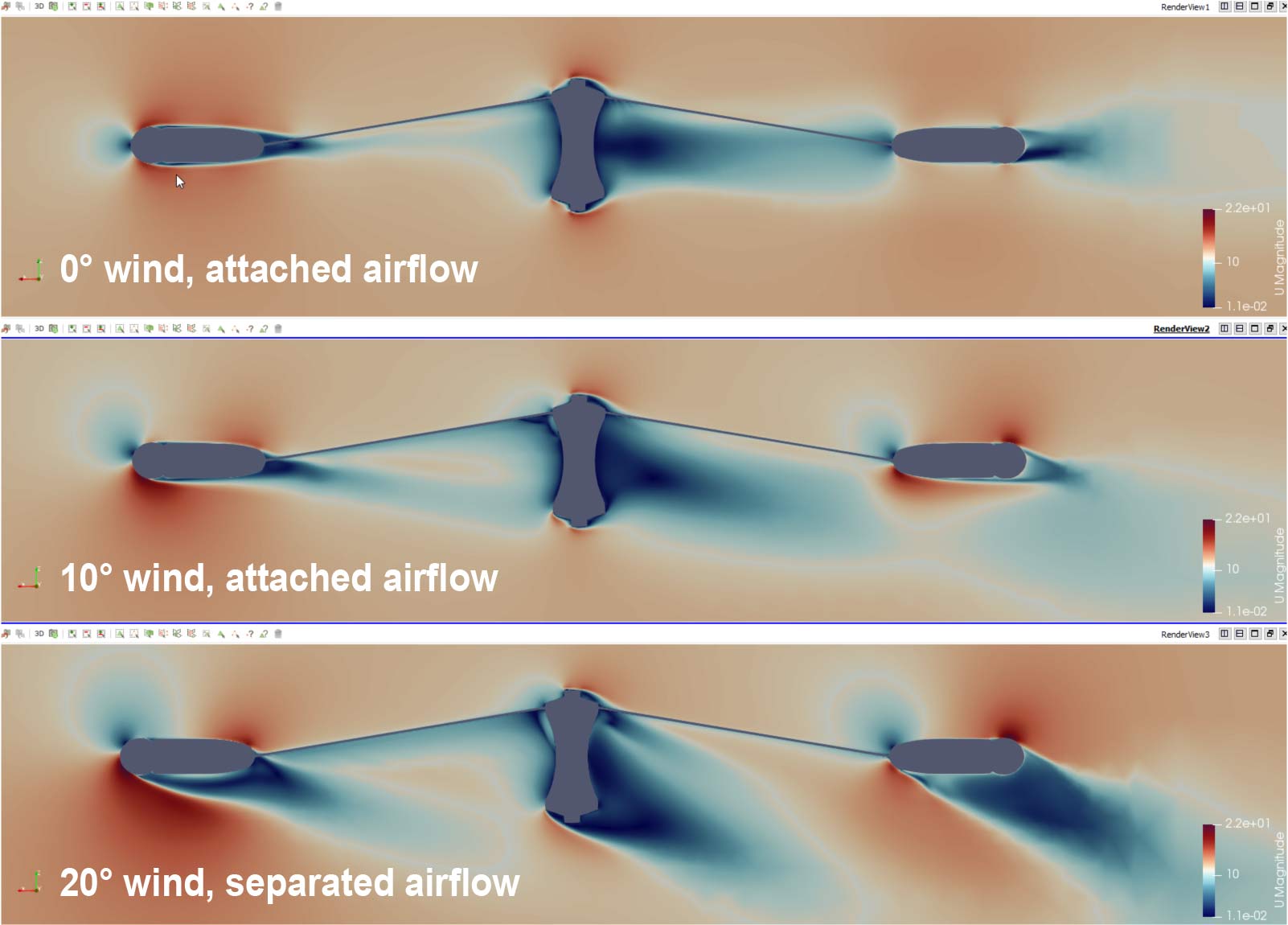

So it was high time that their already solid Bora wheel family got an aero update. The Bora WTO wheels have been wind tunnel optimized for real world racing conditions with a large focus on performance at varying yaw angles, much like we have seen from a number of other wheel makers of late.

The result is two wide new rim brake profiles -60mm & 77mm deep- plus aero optimizations at the hubs and spokes.

Tech details

Both of the new WTO rim depths share a lot of the same tech found on what had been Bora’s previous top end Ultra wheels. That means they still get dynamic balancing with extra material woven into the rim to offset the weight of the valve (which results in a much smoother ride at high speeds). They also feature Campy’s own CULT or USB ceramic bearings for smooth rolling, easy-to-set bearing preload, AC3 braking surface for consistent wet & dry performance, and grouped G3 lacing in the rear wheels.

The wheels also use Campy’s Momag tech which eliminates the need for drilling spoke holes in the rim bed, instead guiding nipples into place via magnets from the valve hole. This is said to allow for a lighter rim bed that is also much stronger, but has the side benefit of making tubeless setups cleaner & easier. And to add to that, these new Bora WTO full carbon clinchers are Campagnolo’s first fully tubeless-ready carbon rims, getting certification for 2-Way Fit (set them up with tubes or tubeless with the included Campy tubeless valve.)

Tubeless, but NO tubulars!?!

We’ve seen it more and more from tire and wheel producers, but Campagnolo has again confirmed that tubeless is the clear winner in decreasing rolling resistance and the obvious way forward. They tested tire rolling resistance with tubulars, with tubes, and tubeless with the five leading 25mm race tires on the market, and averaged the resistance for each at the same pressures.

Tubulars were the worst with a coefficient of rolling resistance of 0.002987, equivalent to 30W of resistance at 40kph for an 87kg rider+bike system. Tires with tubes came in next at a coefficient of rolling resistance of 0.002852, slightly better at 28W of rolling resistance for the same speed and system weight. But tubeless topped both with a coefficient of rolling resistance of 0.002650, the most efficient setup equivalent to 25W watts of rolling resistance.

Since the new Bora WTO wheels are race optimized, they will NOT be made in tubulars, not even for their pro sponsored teams. Everyone will now get the benefits of tubeless as well, with the Bora WTO wheels deep tubeless rim profile, hooked bead, and tire locking shoulder lip.

Aero rim profiles

Campagnolo was aiming for versatile aerodynamic profile designs, but both of these rims are still rather deep, targeting races against the clock where riders are most often riding solo into the wind, rather than in a pack. For now you won’t find WTO profiles from Campy in shallow- or mid-depth wheels for everyday riding and pack racing.

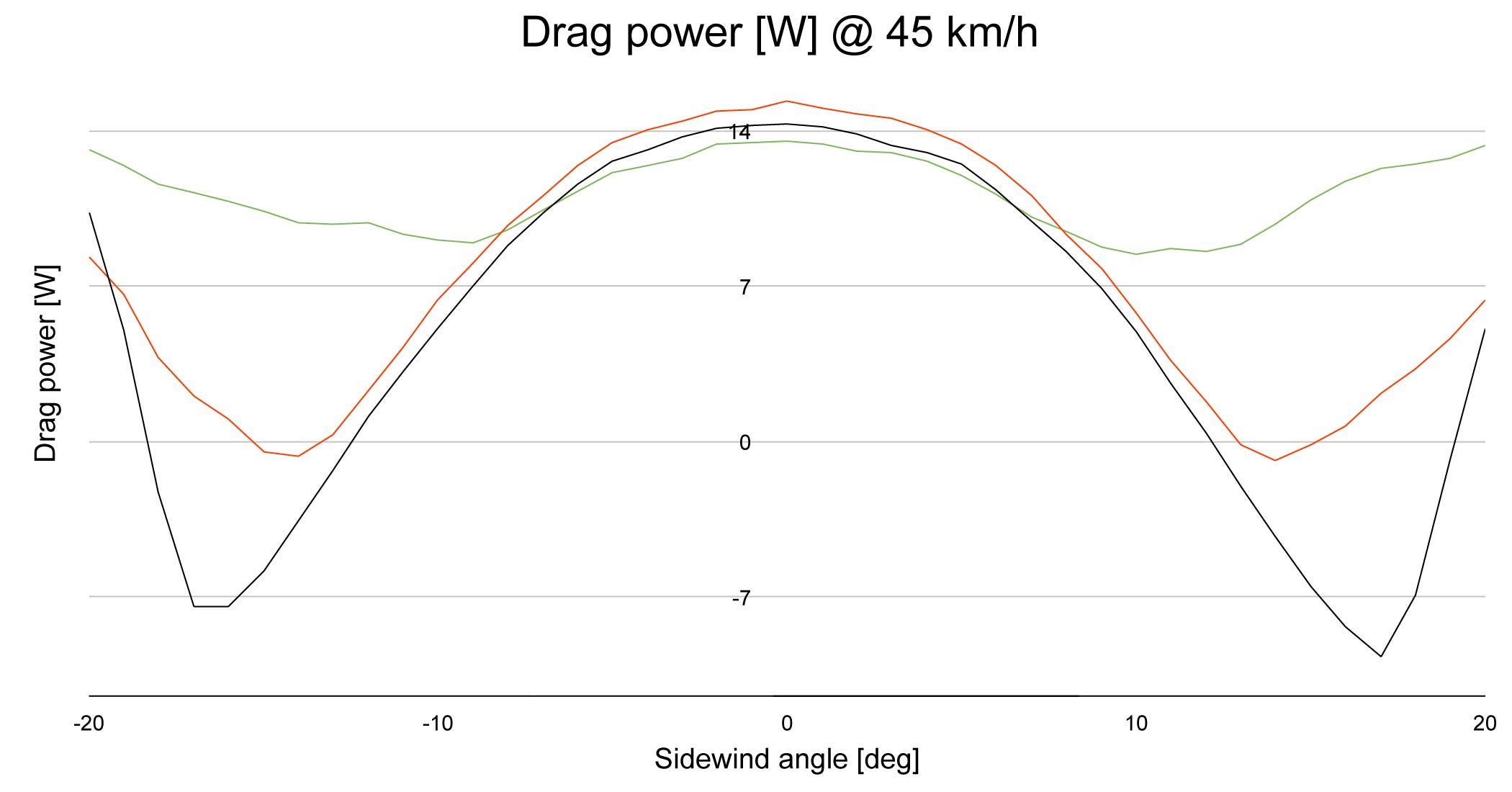

That said, Campagnolo claims that their profiles deliver better overall drag reduction vs. the top wheels on the market. That drag graph shows the Bora 77 WTO in black outperforming an industry-leading 82mm deep wheel in red (assumed to be a Zipp 808 NSW), and another industry-leading tri-spoke wheel in green (assumed to be a HED H3 Plus).

Part of the new aero gains was a balance with moving to wider rims to support the larger 25mm tires that have become the race standard, yet also supporting even wider 28mm tires. The new Bora WTO wheels use Campy’s new standard C19 hooked bead that measures 19mm wide inside and about 26.5mm at the brake track.

The Bora WTO wheels use a quite flat sided rim profile. Campy hasn’t released official rim sections & dimensions. But it appears that the rims are at their widest just below the brake track at 26.59mm, consistently about 25.55mm though the middle of the 60mm deep profile, and then taper to a relatively blunt nosed profile.

Aero hubs and spokes

Bora WTO isn’t just aero rim profiles, to hit their drag reduction targets, Campagnolo also designed a new aero alloy hubset. While we might expect to see a carbon hubshell from Campy at this top race spec level, they do tend to prefer to develop new hubs in alloy first. The alloy, straight pull hub design also allowed for a more aero profile with a very narrow center and sharp angular flanges, at least for the time being. And with Campy’s new 12-speed drivetrain announcement, it is important to remember that these wheels will work with either 11-speed or 12-speed rim brake groups.

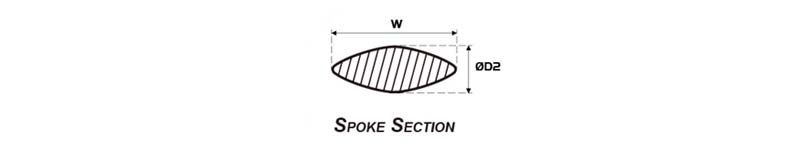

While it is more difficult to see, the wheels also use a new aero spoke profile. Not simply flattened in the center aero section, the stainless steel spokes use a diamond shape that is said to perform better in varying wind conditions. We’re not 100% sure, but they look like the new patented Pillar Wing spoke, quietly debuted last fall.

Campagnolo sticks with external nipples – a necessity with their Momag construction – which maintain usability and have minimal aero impacts (definitely outweighed by the tubeless & weight benefits of their undisturbed rim bed.) The wheels also use a new composite internal rim washer that aligns spoke forces for straighter lines & less stress on the spoke or the hole in the rim.

Bora 60 WTO full carbon tubeless aero wheels

The Bora 60 WTO was designed to be the most versatile of the new aero wheels, and is the only one intended to be used as a pair in road racing situations. As is typical with alloy hubbed Campy wheels, the 60 WTO features USB ceramic bearings. The 60 WTO claims weight of 670g for the front wheel, and 880g for the rear, or a complete wheelset weight of 1550g.

Bora 77 WTO full carbon tubeless aero front wheel

The Bora 77 WTO on the other hand is a wheel designed to be used exclusively in races against the clock – ie. road time trials & triathlons. So the 77mm deep rim is only available as a front wheel, and is meant to be paired with a Bora Ultra TT disc rear wheel. With the move to a more aero optimized design, Campy sees this as an eventual replacement to the current Bora Ultra 80.

Since this is a pro-level TT wheel to be paired with the Ultra disc, Campagnolo is spec’ing the Bora 77 WTO with their top-level CULT ceramic bearings which are said to spin nine times longer than standard steel bearings (and about 4.5x longer than their USB ceramic bearings.) The 77 WTO with its alloy hub is still quite light for such a deep wheel at a claimed 745g, with a carbon hub version already in the works.

Availability

The three new Bora WTO wheels – 60mm front, 60mm rear & 77mm front – are all slated for commercial availability late this summer, with either bright gray or dark black graphics. Pricing isn’t yet set either. So you’ll have to get on a Campagnolo sponsored pro team to race them, at least through the middle of this year’s road season.