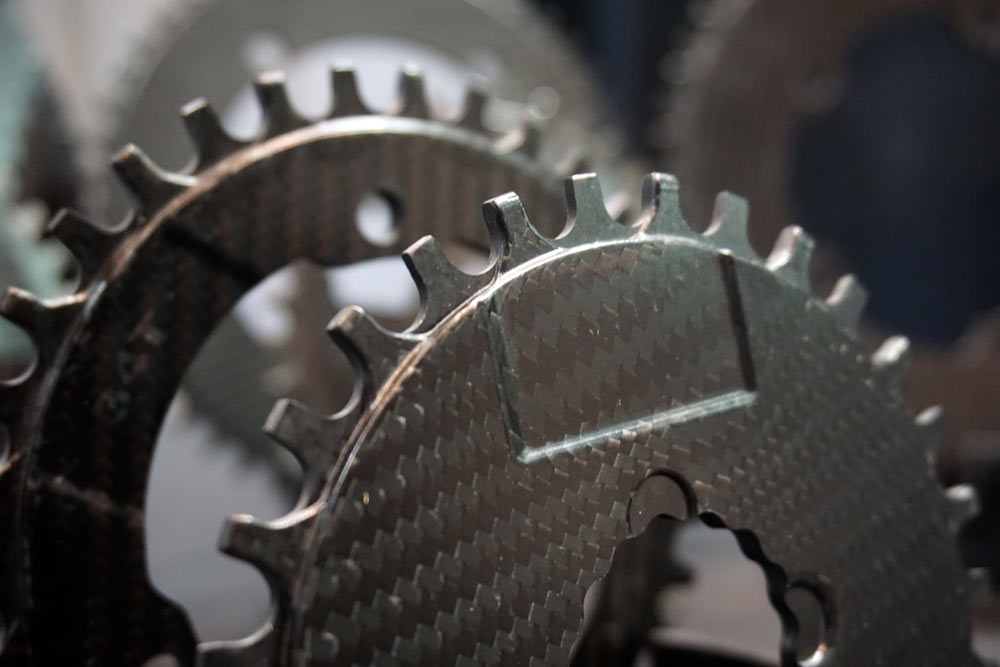

Our friend Tomo, founder of Clever Standard bike tools, was at NAHBS showing off molded layered carbon fiber chainrings. Made by a friend of his, what separates these are that the tooth profiles and widths are molded into shape as much as possible, then only machined from the top down to preserve fiber integrity. He says other carbon rings machine the tooth profiles and widths from the side to get both the width and the shape.

The chainrings come out of the mold looking like this, with the proper width for the narrow-wide teeth pre-formed. Machining happens radially, rather than perpendicular to the ring. Why not mold the entire tooth profile and eliminate CNC’ing altogether? Because the precision tolerances needed for smooth running wouldn’t be tight enough.

Tomo says they’re about 25% lighter than alloy for same tooth counts. They’ll offer Shimano, SRAM DM and Race Face DM options with 30-56 tooth counts for now, but they can open the mold for more based on demand.

They’re designed for anything from road to gravel to cyclocross to mountain bikes, but only in 1x designs. They’re not molding or machining shift ramps into them as that would cause too much wear for this material. They’re still testing for durability against alloy, but say they’ve already proven them longer lasting than other carbon rings.

Retail will be $130 – $150, launching officially at Sea Otter.

If you’re headed there, find them at the Clever Standard booth and their quick-link-opening tire levers and mini chain breaker, along with Silic1 bar tape.