We caught a glimpse of Cycles ED’s biplanar hubs at the Philly Bike Expo, but our attention was mainly drawn to his amazing lugs and frame. Afterward, we reached out to get a little more info on the hubs, which turn out to be equally elaborate and attention worthy.

A custom made frame is one thing. A custom hub is far, far rarer, but each rear hub from Ed Jones is unique, made from hand and uses a lacing and flange pattern that’s unlike anything mass produced. They’re all made on a 1946 South Bend Lathe, which came from Keswick Bicycle Shop, and there’s a story behind all that. As a kid, Ed escaped a troubled home life by working at the shop, and eventually the owner, Rich Norman, gave him a key and invited him to retreat there any time he needed. The shop owner saw the need, and Ed found beauty in the bikes and the safety. That outlook has continued, except now he’s looking for that same beauty and uniqueness in his customers, letting it inspire his design for their bikes. Or hubs…

Here’s how he describes his process:

“My custom hubs are built in the same manner as my frames – no two are ever alike since each are built from inspiration. The frame’s geometry and physical dimensions are all established ahead of building but all artistic accents are incorporated as I build, or more correctly, as I’m led. The idea is that the frame wants to become rather than being forced into some preconceived idea of what it should be. – The final outcome is as much a surprise to me as it is to the owner of the finished piece.

“My hubs are built in much the same way but of course without the same amount of artistic latitude – the base dimension is established such as OLN (over lock nut), bearing size (depending on intended use) and drive system parameters, but little else. A stock of aluminum is chucked in the lath and away I go – little else. It’s how I must work.”

“This is a manual machine, there is no DRO (digital read out) and occasionally I may need to apply a bit of hand pressure to the tail stock or carriage to keep tolerances where they should be. Along with the lathe is a Walker Turner Drill press of approximately the same vintage that was also presented to me when Mr. Norman’s son sold the business.

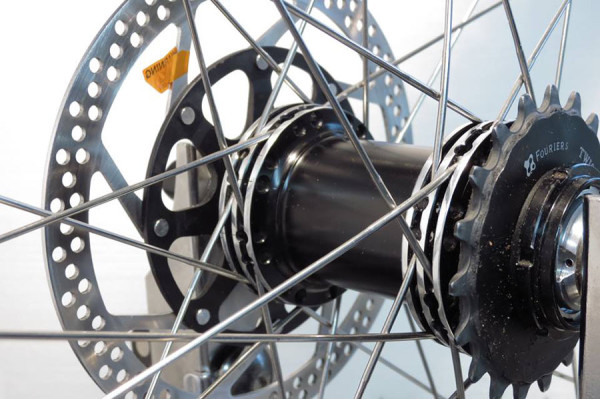

“My term Bi-Planar refers to the unique lacing pattern that I use on many of my custom wheels. But on rear wheels only! It’s somewhat difficult to describe but if you look at the picture of the wood centered hub you’ll see that the spoke pattern consists of the spokes grouped in sets of two. Each flange carries four sets of “Heads In” spokes and four sets of “Heads Out” spokes. A set of “heads in” spokes only physically intersect the spokes of another “Heads In” set, never intersecting any of the “Heads Out” spokes. What this develops is two distinct planes of spokes which radiate from the hub to the rim from each flange. I suppose inclusively you could call it Quad Planar, but that would disrupt the logo!”

“The wheels ride characteristics are very different with this spoke system. Some love it while others are indifferent. Most that have ridden the road version enjoy its tracking aspects during fast, tight, cornering on irregular road surfaces. The mountain version, well, folks find it hard to describe but they do say it’s different. Me? I think it’s beautiful!”

“The silver and black mountain wheel is also a Bi-Planar set up but using straight pull spokes and my own design for fastening the spoke head. I’ve put many hundreds of hours on wheels using this design and have never had a failure or complaint.”

Check out more photos of Ed’s work on his Facebook page.