Building on years of frame design experience both for themselves and others, the new Culprit RAD combines road bike performance with trail capability to deliver an all-in-one road, gravel, adventure, bikepacking, touring bike. With mounts for most anything and tire clearance for days, it’s designed to fill in any holes in your drop bar quiver (or replace it altogether) and look good doing it.

RAD, which stands for Road And Dirt, is a full carbon frame and fork combo that’s being sold as either a frameset or rolling chassis. It’s built around the latest 12mm thru axle standards front and rear, and flat mount brakes. There are three water bottle cage mounts, fender and rack mounts on both ends of the bike, and bento box mounts on the top tube. It even ships with the quick access bento box.

The frame and fork are moderately aero shaped, and funnel all cables and hoses inside to reduce drag and improve looks. Any drivetrain and braking setup will work, with multiple cable ports on the top tube (directly behind the steerer, feeding down toward the downtube…which takes advantage of their new integrated stem concept shown below) or letting you run things through the steerer with compatible bars and stems.

The bike is built and tested to handle anything you’ll take it on, and by simply swapping wheelsets, you can easily transition from pure road to fast gravel to backcountry dirt road touring or more. The frame and fork will fit up to 700×45 tires (700×32 with full fenders), or 650×2.1 gravel or mountain bike tires.

Rack mounts can handle up to 25kg in the rear, and 9kg up front. Use those plus a saddle bag and handlebar roll and you’re ready for multi-day touring. It an extremely versatile frameset that somehow pulls off looking good in any configuration.

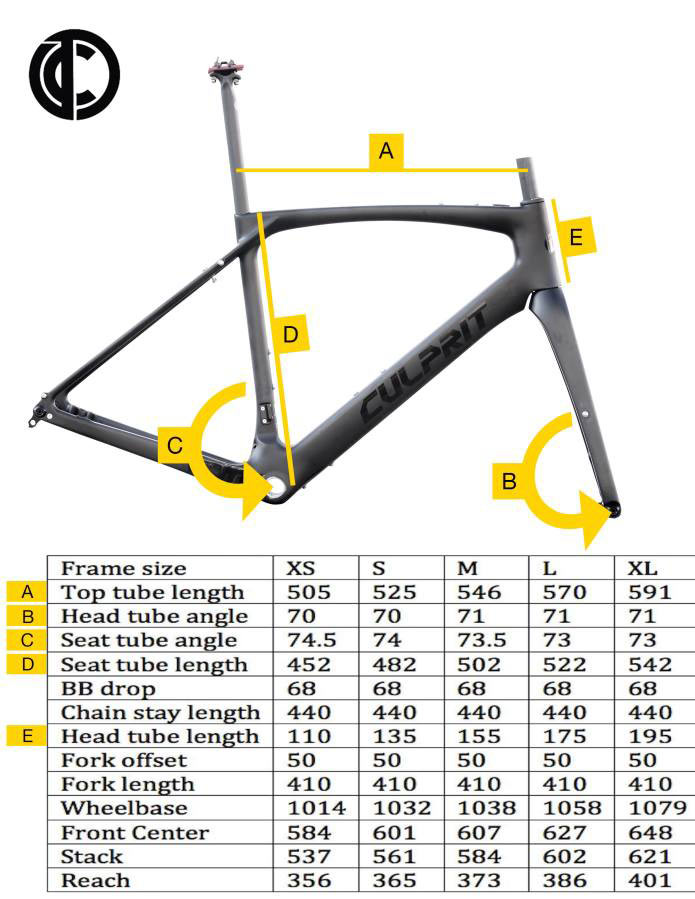

The matte carbon frameset comes in five sizes, from XS to XL, with three logo colors to choose from: gloss black, neon yellow, and neon pink. Framesets will have an MSRP of $1,650, but are available on their IndieGoGo launch for 25% off ($1,235) and includes frame, fork, headset, seatpost (0mm or offset), thru axles and bento box.

A frameset with cockpit adds their new ergo aero carbon handlebar (which is very nice, full details in the campaign), and your choice of the integrated or standard carbon stem for $1,495 ($1,995 MSRP).

The rolling chassis adds your choice of their aero 50mm deep 700c carbon wheelset (Venn rims, Token hubs, Pillar spokes) or 35G 650B carbon mountain bike wheels (Culprit’s rims, Token hubs, Pillar spokes) for $2,425 ($3,245 MSRP).

The wheels, handlebar, stems and two different tool kits are all available on the campaign, too. The latter packs everything you need to fix your bike (plus room for any small paraphernalia you like to take on your adventure rides, snacks or otherwise) into either a saddle bag wrap or a bottle-shaped soft case with interior organization to keep it rattle free.

Included in the campaign as a separate item is their new Covert Ops stem, which allows you to hide the cables and any junction box inside the main compartment without having to reset your handlebar position. It’s made to spit the cables out the back, where many triathlon bikes route the input, or run things into the steerer for compatible forks.

It’s also designed to work with their new aero bars system, which lets you set the mount and handlebar position once, then tweak aero bar position independently so your position remains consistent even if you have to travel with the bike. For anyone looking at this bike as a long distance tourer, it’s a good add-on to consider.

All packages include free shipping to North America, Europe and Asia. Shipping is charged for other countries. We had a chance to preview the bike for a three hour ride around Culprit’s home base, and it’s a great bike. Short ride review coming soon!

Check the IndieGoGo campaign here.