Behind the scenes of many of your favorite bikes, there is a world of Original Equipment Manufacturers that is rarely seen. Working directly with one of the number of name brands they service, the bikes are built to the company’s specification and then shipped off to their destinations. Over the last few years though, a few of these OEM builders have realized that if they can create their own brand, they stand to gain a bigger slice of the pie, so to speak.

That seems to be the case with relative newcomer Dare Bikes. Founded in 2011, Dare is using their OEM experience from building bikes for brands like Lapierre, Norco, and Haibike, to launch a brand of their own. More than just creating their own brand though, Dare claims to have worked directly with Toray to develop a new carbon fiber – one that promises to push carbon frame design to even greater heights lower weights. Now focused on entering the U.S. market place, Dare is introducing a new aero road bike that can be equipped with both rim and disc brakes…

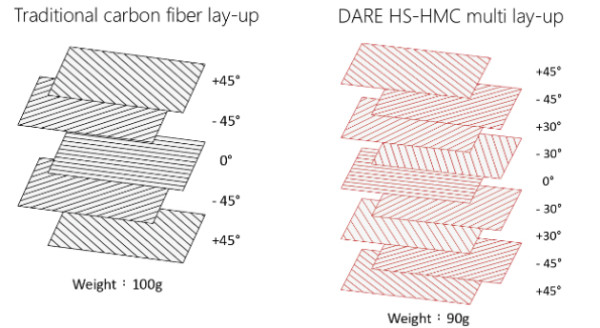

At the heart of the Dare VSR road bike construction are claims of a new carbon fiber construction method that Toray developed in conjunction with Dare. Referred to as a Multi-Ply Synthetic Hot -Melted Carbon Fiber Resin (HS-HMC prepreg), this new method uses more plies of carbon fiber but has a lower weight per square meter. Using 9 different layers of carbon, each layer is half the thickness of traditional plies which results in a lighter FAW (Fiber Areal Weight)(g/m²) with the same wall thickness. Due to the addition of extra plies in additional angles the frames can supposedly be made to be more stiff, lighter, and stronger. Dare frames are said to test at least 20% better than current EN or ISO standards in spite of the lower weights. Additionally, the frame is comprised of T1000, M40, and M46 carbon fiber.

While the carbon technology is definitely a talking point, the real interest in the VSR will likely come from the smart design which gives the rider options when setting up their ride. This isn’t the first bike we’ve seen to try and integrate both rim and disc brakes, but it might be the cleanest. We have one of these on the way for review so we’ll get more detailed pictures later, but the VSR includes the option to run direct mount rim brakes at the rear under the chainstay with 130mm dropouts, or post mount/flat mount disc brakes with 135mm dropouts. When not in use, either brake mount includes an integrated cover to keep things clean.

While the fork is compatible with either post mount (with adapter) or flat mount disc brakes, a different fork is needed to run rim brakes. Both front and rear axles stick with standard quick releases, with the rear using two different drop out sets to switch from 130 to 135mm.

Along with the brake flexibility, the VSR has been designed to be as aerodynamic as possible with their Vetox tubing profile and integrated aero headset and hidden seat clamp. The ABAS (Aerodynamic Battery Ready Adjustable) seat post is adjustable from 73 to 77º and includes an internal Di2 battery holder. Just in front of the rear rim brake position you’ll find an asymmetric BB86.5 press fit full carbon shell

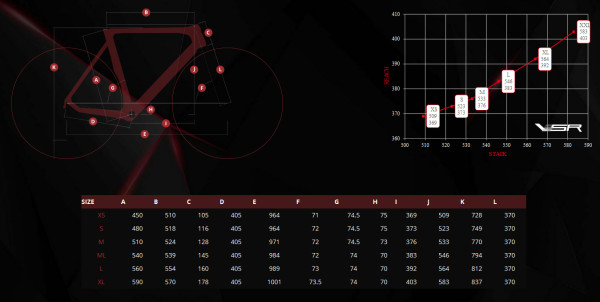

Offered in 6 sizes, Dare bikes will eventually be available in the US. We’ll have more information on pricing and availability in the near future along with full details and hands on impression. In the mean time, check out dare-bikes.com for more.