At Eurobike 2023, Ben Jones and Chris Deverson of Deviate Cycles gave us a preview of their prototype high-pivot downcountry bike made from titanium and carbon – a bike we now know as the Lowlander. The stunning frameset was produced as part of Deviate’s exploration into how they can bring manufacturing to the UK at a price that is competitive with the Asia-made carbon frames.

Now, we learn there is a second prototype titanium bike from the Scottish brand, aptly named the Tilander. It’s a 145mm travel high-pivot bike, very much based upon the 145mm Highlander. Here’s a closer look at the Deviate Tilander, along with some insight into the Cold Metal Fusion process used to produce it.

Deviate Tilander Prototype

The Deviate Tilander is one of the most attractive titanium mountain bikes we’ve laid eyes on. Sadly, it is not available to purchase, and indeed it may never be. Its creation was something of a proof-of-concept, an early-phase prototype produced as a learning tool for Deviate whose ambition, ultimately, is to manufacture frames in the UK.

Currently, the Claymore and Highlander frames are produced in Asia from carbon fiber, but the brand see a future where some, or all, of their frames are produced from titanium in the UK, or more specifically, Scotland. From a technological standpoint, it is entirely possible; there are plenty of boutique brands offering UK-made titanium frames, but costs are somewhat astronomical.

There will always be a small portion of the market willing to pay the price for titanium’s high strength-to-weight ratio, its isotropic properties and of course, its strikingly beautiful aesthetic. But, Deviate want to do things differently, producing titanium frames at a price competitive with Asia-made carbon frames.

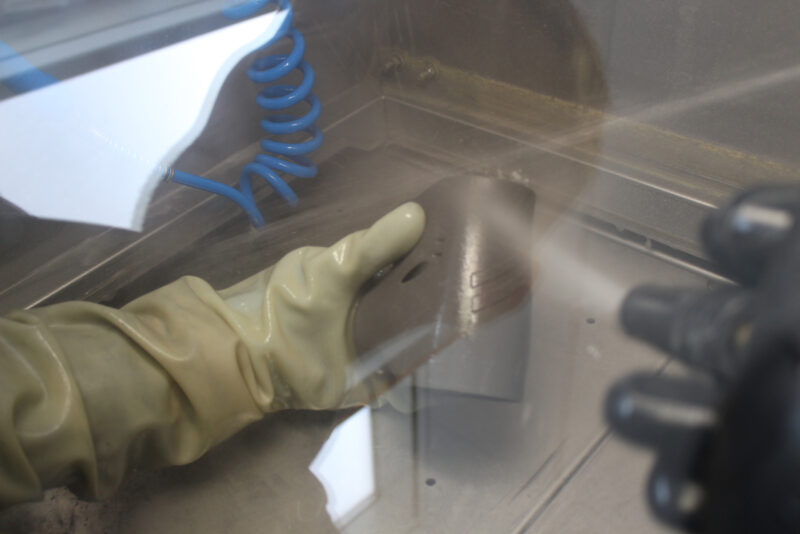

It is a bold ambition. Working with titanium is infamously difficult, requiring much more tightly-controlled manufacturing conditions than those needed for steel or aluminum, and oftentimes tens of hours of manual post-processing. Those are two factors that contribute to the high costs usually associated with titanium bikes, not to mention the cost of the material itself.

But, Ben and Chris from Deviate Cycles believe they may have stumbled across a more economical, cost-effective method of manufacture. Admittedly, they aren’t anywhere near the production cost they’re aiming for just yet, but forecasting that considers the scalability of the method suggests it’s certainly not impossible.

How were the Deviate Tilander and Lowlander produced?

Their titanium lugs were created via a method of 3D printing referred to as Cold Metal Fusion, or CMF. And, it is executed by Element22, a company based in Germany that uses a process developed by Headmade Materials.

It uses uses a powdered form of titanium, each particle of which is coated with a polymer. The 3D printing process melts the polymer, and then the sintering process removes it while simultaneously annealing the metal. The method is said to produce titanium parts that have around 97% the density of a machined block of titanium, and at a significantly reduced cost.

“The surface finish is smoother, so we don’t need to spend as much time finishing. We can print those parts floating in a powder bed with no support. We only need minor supports to hold everything together during the sintering – before we sinter it, the 3D printed part has roughly the texture of chocolate”

Johannes Schaper, Element22 Operations Manager

Of course, fewer supports also means less waste.

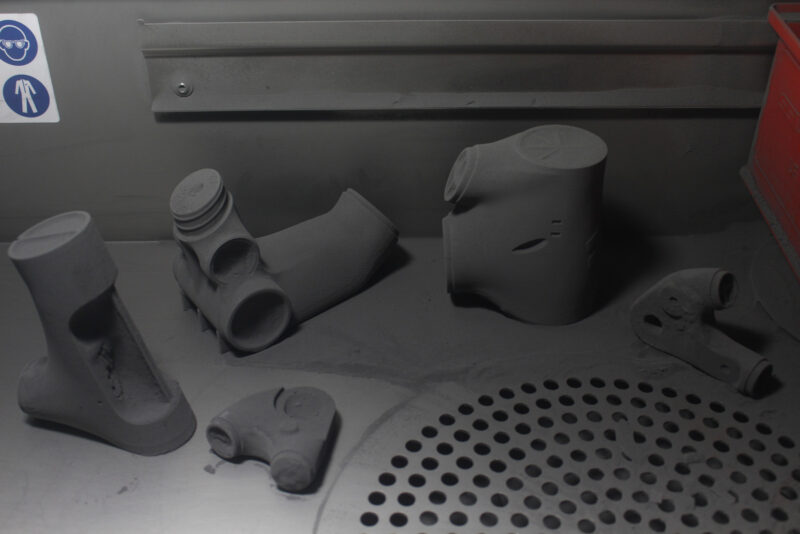

Johannes is referring to the structures that are created in conjunction with the part that necessary to hold it in place as it comes into being. You can see examples of these structures in this half-finished build plate of Atherton Bikes titanium lugs.

“When it comes to material, we only use what’s needed. In aerospace they call it the “buy to fly” ratio – we have a buy to fly ratio of nearly one, which is as good as it gets. We’ll have a tiny amount of loss in loose powder but if something goes wrong, we can actually reuse that loose powder that we take off, and we can also reuse broken parts before they’re sintered.” – Johannes Schaper.

Deviate’s efforts are certainly to be applauded, but they’re wasted if the bike doesn’t ride nicely. On this, Chris Deverson says, “Well, it’s beautiful to ride a titanium bike, of course and the Ti-lander acceleration response is totally unlike the carbon frame! There’s a certain spring to your inputs that’s difficult to describe. But it’s certainly a good feeling“.

We’ll be staying in touch with the guys at Deviate to follow the evolution of Project Tilander. For the time being, you can follow their exploits on Instagram @deviatecycles.