Grinduro season is upon us. To celebrate the second installment for the year, Devinci Cycles is not only hosting the event for the first time in Canada, but they’re launching a new gravel bike as well. First introduced in 2016, the Hatchet is being resharpened into an ultra-modern gravel bike with updated geometry, dropper compatibility, more mounts, and room for huge tires.

Positioned in northern Quebec due to the area’s expertise in aluminum manufacturing, Devinci’s headquarters are also close to a Provincial park with an expansive network of forest roads. Those very roads were the inspiration for the original Hatchet in 2014 as they were a bit too long to explore by mountain bike, but too rough to ride with the typical road bike. The gravel bike market was just starting to grow at that point, and Devinci was seeing a shift in how riders viewed the opportunity to do longer rides away from traffic.

Devinci also took note of the growing trend of gravel racing after the first Grinduro was held in 2015. Thanks to a fun combination of racing and party atmosphere, they used the second annual Grinduro as the launching point for their first Hatchet. Now, after meeting with the Grinduro team on their home turf last fall, Devinci is bringing the Grinduro format to Canada along with a substantially different Hatchet.

Depending on who you talk to, tire choice for gravel racing tends to vary with substantially different widths and sizes. Devinci says that as soon as they knew that wider 700c gravel tires would be available in the future, they wanted to build a bike that was capable of running them. These wider treads make the bike more capable but also more comfortable in a wide range of conditions. Because of that, the new Hatchet has tire clearance for 700c x 45mm or 650b x 2.1″.

However, those numbers don’t quite tell the full story. In this case, the 700c x 45mm clearance is pretty conservative. Devinci says that they wanted to be able to state that you could run any 45mm tire on any rim and at any pressure. You can even run 700c x 45mm tires with full coverage fenders! As a result, the bike actually has the ability to run 700c x 50mm tires – but it’s one of those run-it-at-your-own-risk scenarios. They mention that they don’t officially list it as 50mm clearance since running certain tires on certain rims at high pressure may cause it to rub or not provide enough mud clearance. But our entire time on the bike so far has been on 700c x 50mm Maxxis Rambler tires mounted to Easton EA90 AX rims with a 25mm internal width. And with that set up, there’s plenty of clearance for the dry conditions that we’ve been riding it. One of Devinci’s engineers has even been riding it with 650b x 2.4″ Schwalbe tires, so it’s safe to say that this thing has mega tire clearance.

To get there, Devinci uses a full carbon frame with dropped chain stays on both sides of the frame. They mention that this was difficult to design thin enough to provide the necessary clearance for both the tire and the chainrings, but the results speak for themselves. As for those chainring clearances on the carbon frame, for 1x drivetrains there is a minimum chainring size of 40t (Devinci admits it can handle a 38t though there might be a little chainslap on the bottom of the chain stay) and a maximum chainring size of 48t. For 2x, it can run 46/34 to 52/36 combinations. The minimum size is to ensure that the chain clears the bottom of the dropped stays, and Devinci clarified that the alloy frame can fit slightly bigger rings.

Devinci put a lot of effort into the design of the carbon bike to make it as clean as possible in terms of its outward appearance. That means a capped front axle on the full carbon fork, sculpted lines that flow from the frame into the fork, a stick-on front derailleur cover, and all of the accessory mounts on the inside of the frame and fork with the exception of the rear rack mounts. The carbon frames get a fork that doesn’t include front rack mounts. This is because the carbon version is geared towards racing and aggressive riding. The aluminum versions of the Hatchet include a taller head tube, more fork mounts, and the idea that they’ll be more adventure/all road/commuter focused.

Compared to the original Hatchet, Devinci had the same stiffness targets but ended up with a frame that was slightly more stiff at the front. Part of that was in response to the use of larger tires in order to keep a racey feel to the handling. Frame compliance was also a big focus as these bikes need to be as comfortable as they are capable. The frames utilize a dropped stay design that is artistically integrated with an s-bend at the seat tube that flows from the top tube into the stays. This structure is actually hollow with a seat tube bonded inside, and uses fiberglass reinforcement at the seat stay junction to aid in carbon compaction during the molding process. Like most Devinci carbon frames, the Hatchet is made using an EPS molding process, and the tubing sizes and shapes have been optimized using FEA to ensure that each frame size offers a similar ride quality.

Cable routing is all internal with a revised version of their ‘intake port’ design. All of the cables for the back of the bike enter into a port just behind the head tube which has two caps. One allows for any combination of mechanical drivetrain plus a dropper post, and the other is meant for Di2 drivetrains and a dropper post. Devinci points out that no matter what type of sealing you use for the frame openings, water and grit will always make their way inside the frame. This is why they choose to run full cable housing without any cable stops. To make the lightest routing system and the quietest, they use foam tubing around the internal cables housing with a single tube for the cables from the intake port to the BB access hatch, and separate tubes from the BB hatch to the two chain stays. Thanks to the large openings in the frame, routing is said to be very easy, and our testing seems to confirm that it’s completely quiet as well.

As mentioned, all Hatchets have the ability to run an internal 27.2mm dropper post, even the aluminum ones. Builds that include one as stock will use a KS dropbar lever which is mounted inside the left shifter hood. Most of the complete bikes will not include a dropper post, but you can always add one in the future – which if you’re riding aggressive trails like those used in part of Grinduro Canada, you’ll definitely want one.

Those aggressive trails bring up an important factor in the Hatchet’s design – unlike many road and cyclocross bikes, the Hatchet is designed with jumping and aggressive riding in mind. Clearing small doubles on a mountain bike trail might not seem commonplace for many gravel riders, but as we’ve seen, these bikes are certainly capable. So building a frame that will stand up to the abuse is part of what sets these bikes apart.

Going along with the more aggressive riding styles, the carbon frame includes 160mm flat mount brakes front and rear. Devinci didn’t see many riders using 140mm on the rear of the original Hatchet, so they decided to eliminate the adapter and go with a dedicated 160mm flat mount.

Carbon frames also include ample protection with a molded chain stay protector that covers the top and bottom of the chain stay. The bottom bracket is also covered with a large skid plate, and production frames will include a 3M protective decal on the downtube to protect the paint from rock strikes.

And while the frames are built to tackle aggressive riding, they’re also equipped to handle long days on the bike where endurance is more of the focus. Three bottle cage mounts are included with two inside the front triangle, and one on the downtube. Top tube bag mounts are offered for bolt-on gas tank style bags, and the frame has the ability to run a rear rack as well. If you need even more storage, you could purchase the carbon fork for the aluminum models which includes a front rack mount as well. Full coverage fender mounts are hidden with two different mounting locations on the seat stay to accommodate different fenders.

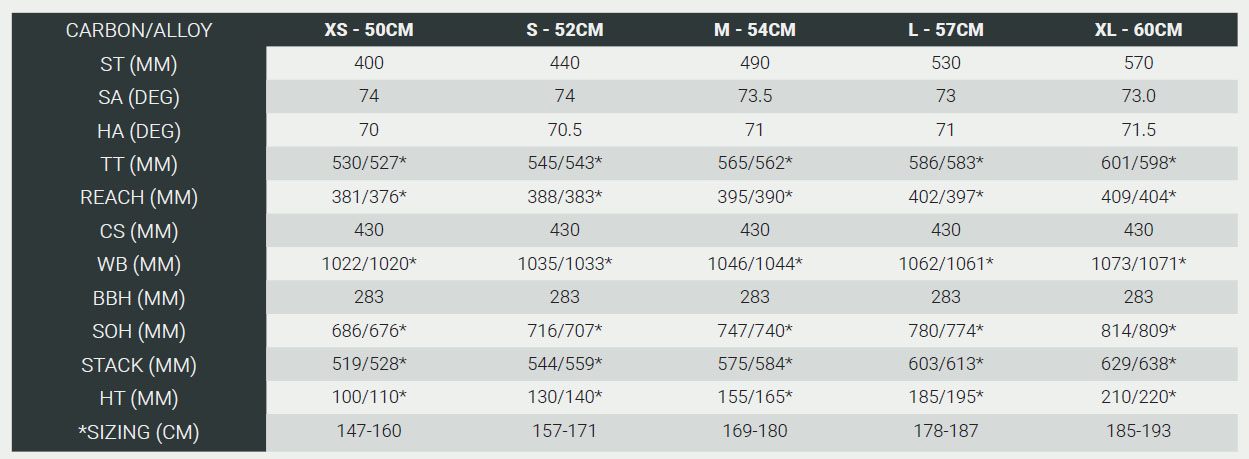

Similar to other more modern gravel bike designs, the Hatchet moves to a more mountain-bike inspired geometry based around longer reach and shorter stems. Combined with a 50mm offset fork, this reduces the chance of any toe overlap, and provides precise steering in technical situations. The increase in reach numbers is size specific with larger frames getting proportionally longer reaches. While the head tube angle remains the same at 70-71.5º depending on the size, the seat tube angle has gotten a little steeper slacker at 74-73º and the frames are designed around a zero offset seatpost to work well with droppers. Chainstays have been kept fairly short at 430mm, especially when you consider the amount of tire clearance.

Other key frame details include a BB386EVO bottom bracket that will work with 24 or 30mm spindles, 12 x 100 and 12 x 142mm thru axles (rear axle is uncapped so it remains trainer compatible), and there is an IS tapered headset. That headset has the option of running an additional spacer cup to adjust the geometry if you decide to run 650b wheels and tires.

In terms of drivetrain options, all of the “gravel” builds will include a 1x drivetrain. The “all-road” and road builds will include 2x drivetrains along with narrower bars and 32mm slicks in the Road build. Devinci positions the aluminum bike as the more adventure focused model, where the carbon bike is geared towards racing and aggressive riding.

In stores now, the Hatchet is available in four carbon builds, and eight aluminum builds. Weights are claimed at 1135g for a medium carbon frame with all of the hardware and parts and 460g for the matching carbon fork. Stay tuned for a complete model breakdown and first ride report!