Way back in 1978, Diamondback Bicycles was born into the early days of BMX racing. While the brand stuck with 20” bikes for some time, they have more recently pushed into road, hybrid and full-suspension MTB territory. This year, their Podium competition road bike has been completely redesigned from the ground up, resulting in additional stiffness, significant weight savings and greatly improved aerodynamic efficiency.

Way back in 1978, Diamondback Bicycles was born into the early days of BMX racing. While the brand stuck with 20” bikes for some time, they have more recently pushed into road, hybrid and full-suspension MTB territory. This year, their Podium competition road bike has been completely redesigned from the ground up, resulting in additional stiffness, significant weight savings and greatly improved aerodynamic efficiency.

Extensive computer modelling, wind tunnel testing and real-world ride testing with the Optum Pro Cycling team were all employed to find areas for improvements. Opportunities were discovered and Diamondback ran with whatever produced the best results, even when their findings were contrary to prevailing industry opinions…

The new Podium’s frame is constructed using Diamondback’s AMMP SLP process, a monocoque molding technique that uses high modulus carbon to create very light, thin tubes. A mix of carbon laminates is strategically employed around the frame with unidirectional 40T carbon in the straighter sections and less brittle 30T and 20T for more shapely areas and where compliance is important. Diamondback says partly due to the large, stiff downtube and round seat tube, they’ve accomplished an ideal balance between vertical and torsional stiffness. The revisions are quite noticeable versus the Optum Team Replica model we checked out last summer.

By using a unidirectional carbon weave wherever possible with some woven sections for reinforcement they’ve optimized the frame’s weight, stiffness and strength. The new frame is 100g lighter, yet notably stiffer and 50% more aerodynamic across all yaw angles than the outgoing version.

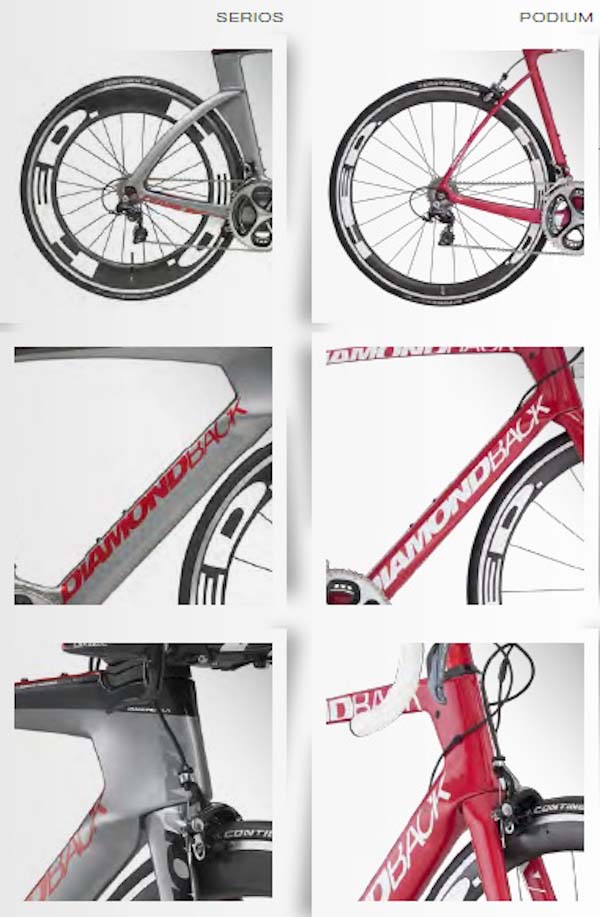

Diamondback spent a lot of time and effort developing their current Serios Triathlon/Time Trial frame, and some of what they learned about tubing shapes, airfoils and tuning ride quality carried over into the Podium’s development. The Podium incorporates similar curved seat stays, airfoil shapes and a wide and deep downtube, but each are uniquely refined for their new application. For example, the trailing edges of the Podium’s airfoils were trimmed down to just under half the length of the Serios, which DB says saves weight and increases stiffness in the frame.

The company has partnered with the Optum Pro Cycling team to gain crucial feedback regarding real-world performance, and they’re already seeing results. Racer Phil Gaimon won the Redlands Classic and several stages of the Tour De Gila riding the newly improved Podium. While Diamondback values input from their pros, they’re also keeping the average consumer in mind. The Podium is designed to excel at anything from short training rides to lengthy mountain race stages, and it’s reduced weight, improved stiffness and aerodynamics provide a benefit to riders of all levels.

Other frame details include Diamondback’s ‘closed circuit’ internal routing which completely hides your brake and derailleur cables (mechanical or Di2) but leaves easy access for servicing where they pass through the bottom bracket shell, and carbon dropouts with replaceable aluminum hangers. The fork was also redesigned to be highly aerodynamic, but Diamondback stuck with non-integrated brakes to keep it simple and serviceable for the consumer.

Three complete models of the Podium are available at different price points- the E’Tape (105 components, $2700), Vitesse (Ultegra, $4500) and Equipe (Dura Ace mechanical, $7500), plus Diamondback is offering a Podium Optum frameset for $2300.