DT Swiss say they’ve ‘broken the mold’ with their new top-tier 1200 series race-ready carbon mountain bike wheels. And what they actually mean by that, is they’ve ditched their old carbon rim molding for a new rim manufacturing process that maxes out compression of the carbon fiber layers during production in more precise tooling that requires no post-finishing. The result is straight out-of-the-mold carbon rims that DT can quality control layer-by-layer, which are now more durable and lighter. Whether you are racing XC, exploring all-mountain, smashing enduro stages, or even shredding lightweight eMTBs.

All-new DT Swiss 1200 series lightweight carbon MTB wheels

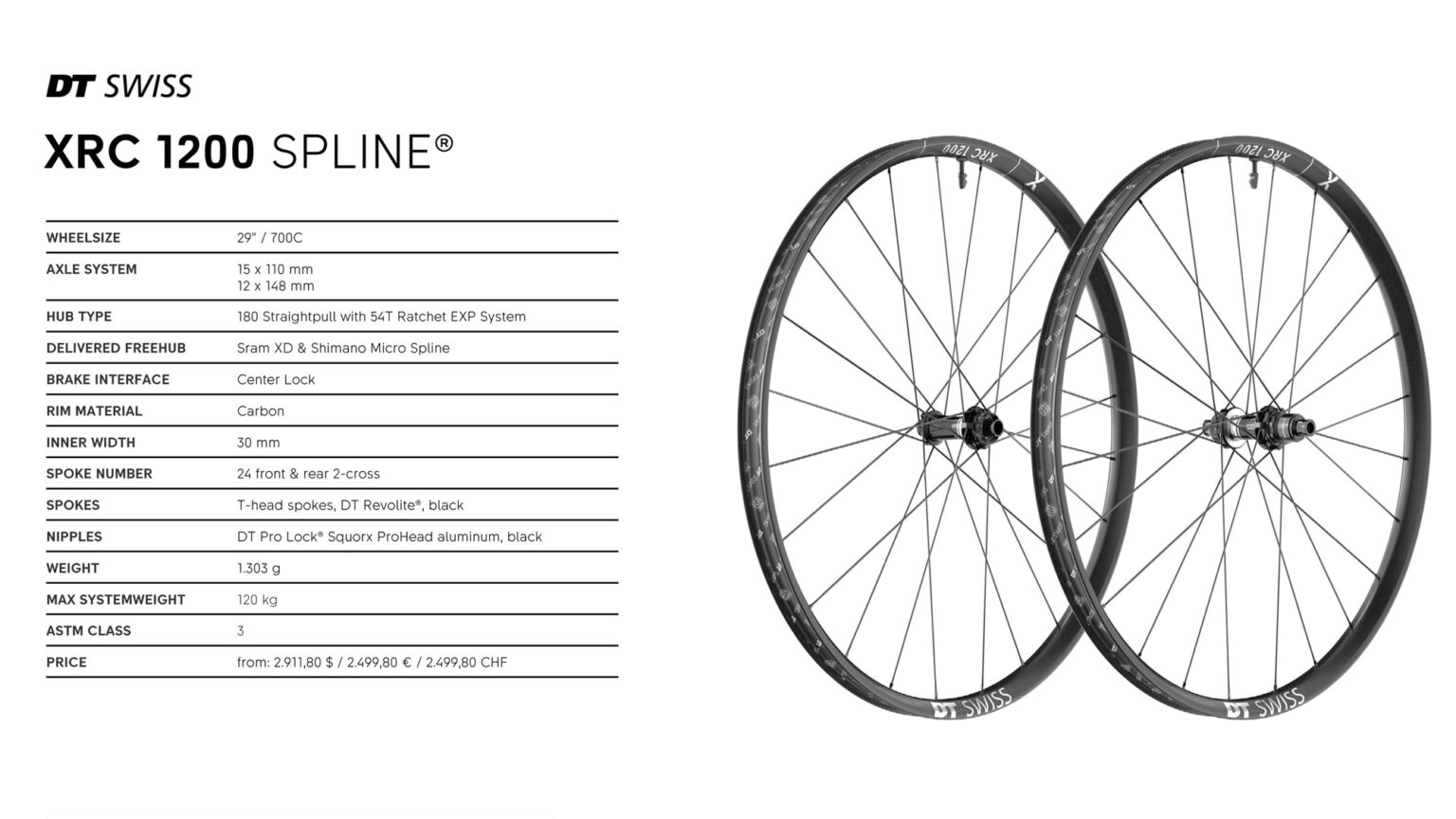

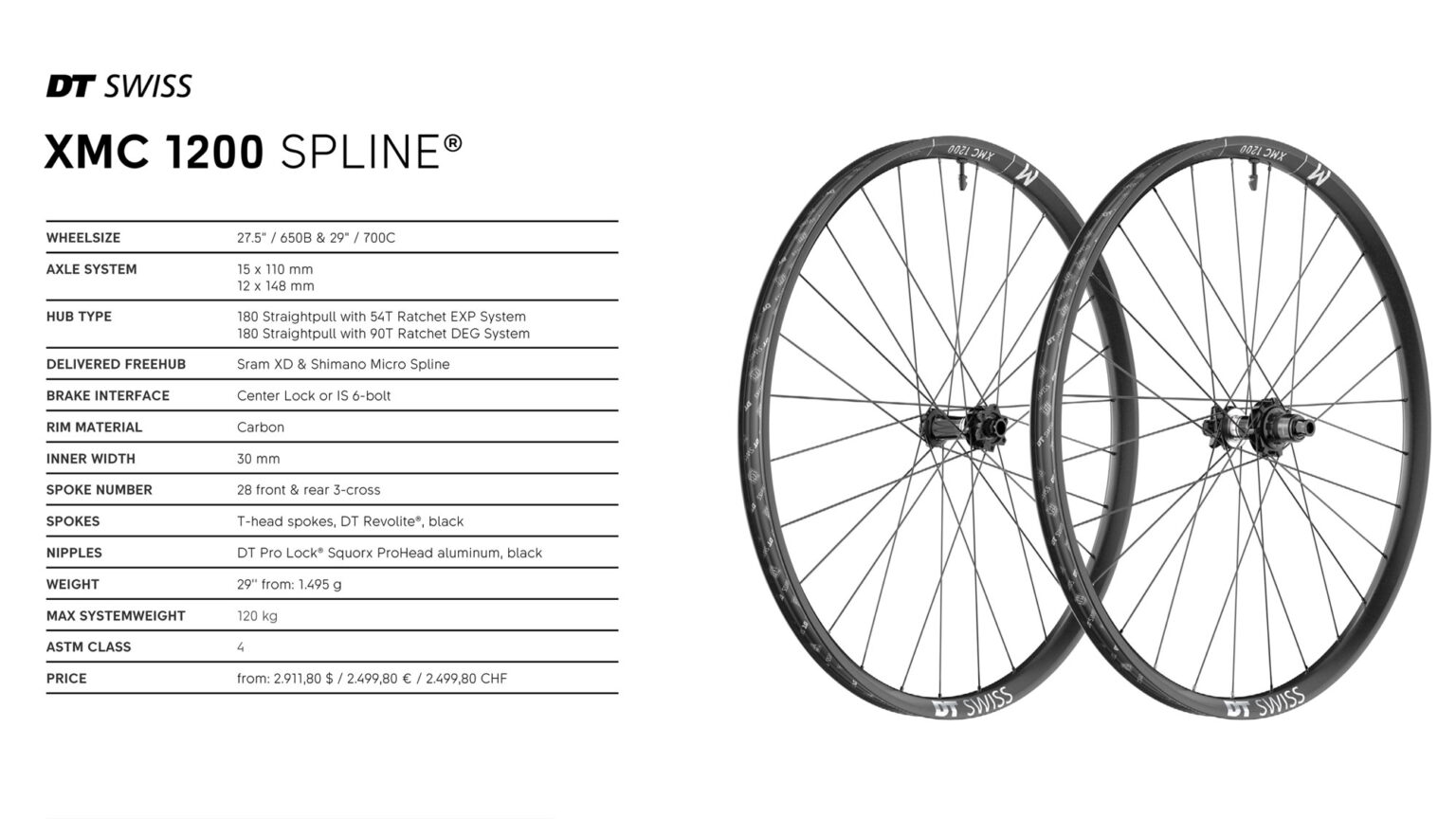

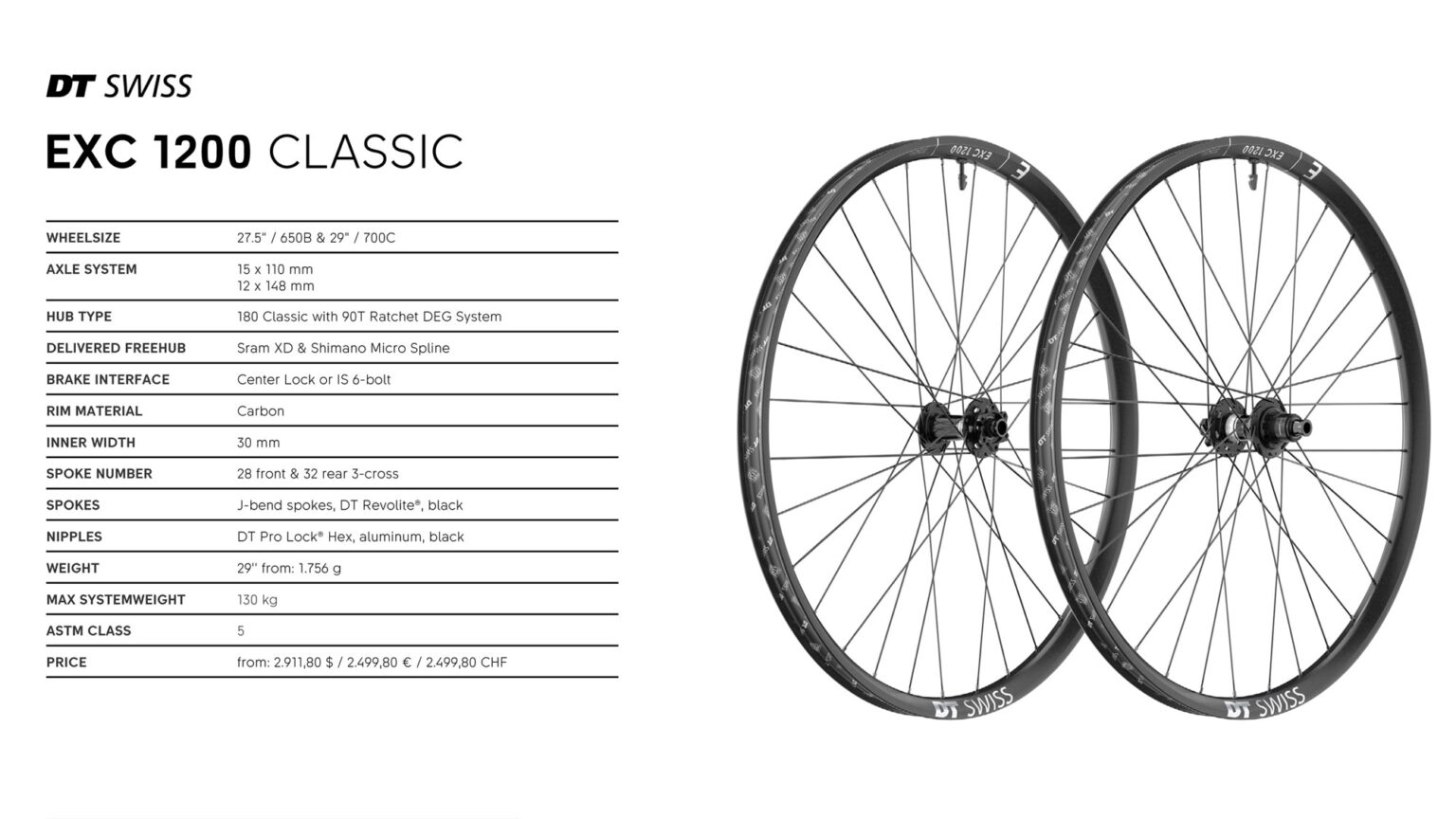

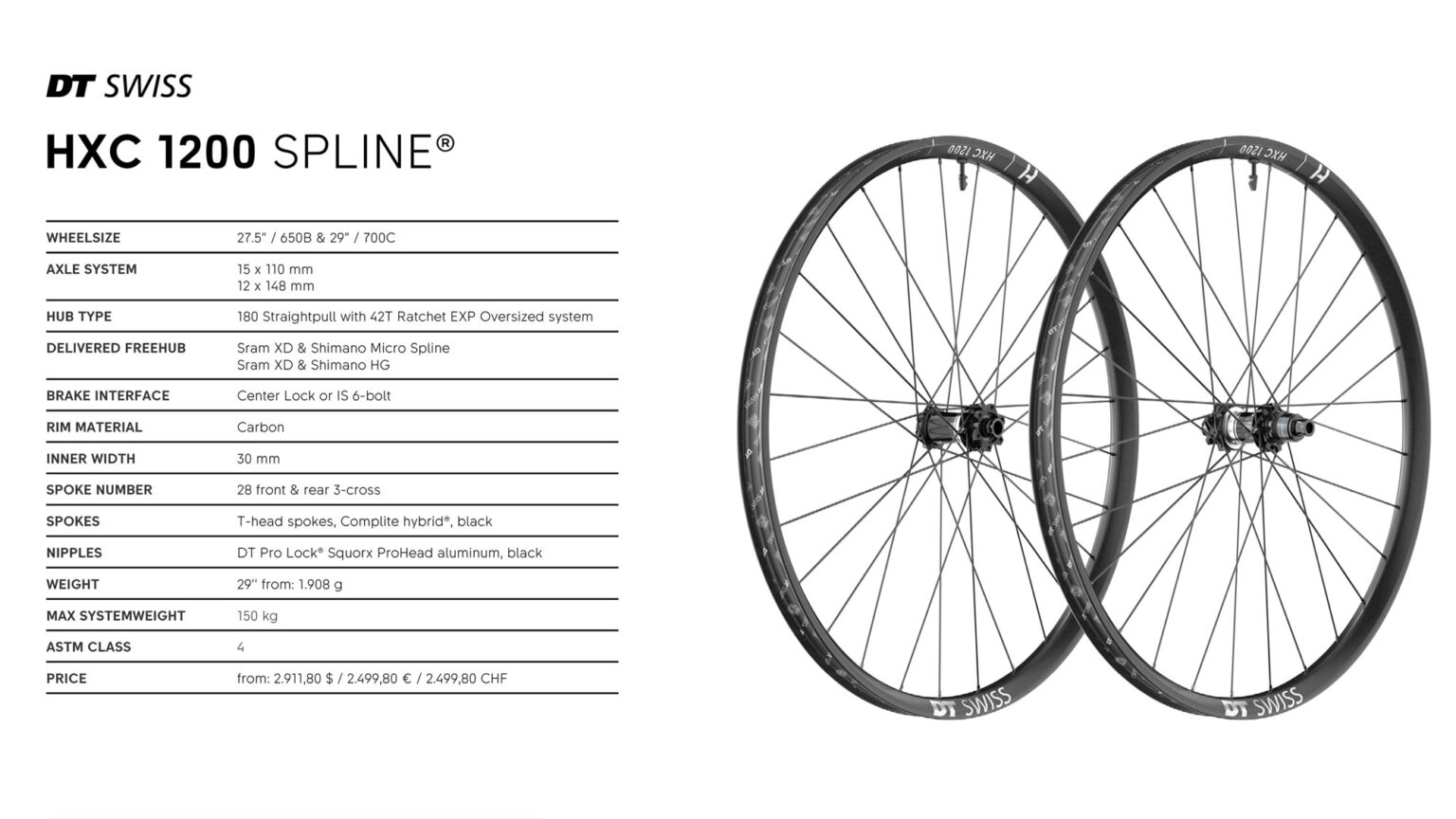

4 wheelsets. 4 new carbon rims. Discipline-specific hub and spoke specs. And race-ready 1200-series carbon MTB wheels for XRC cross-country, XMC all-mountain, EXC enduro, and HXC lightweight eMTB.

What really sets them all apart is the new carbon rim construction, which DT Swiss describes as unique to the cycling industry. But of course, the new “industry disrupting rim manufacturing process” is patent-pending so the details are quite vague.

What do we know?

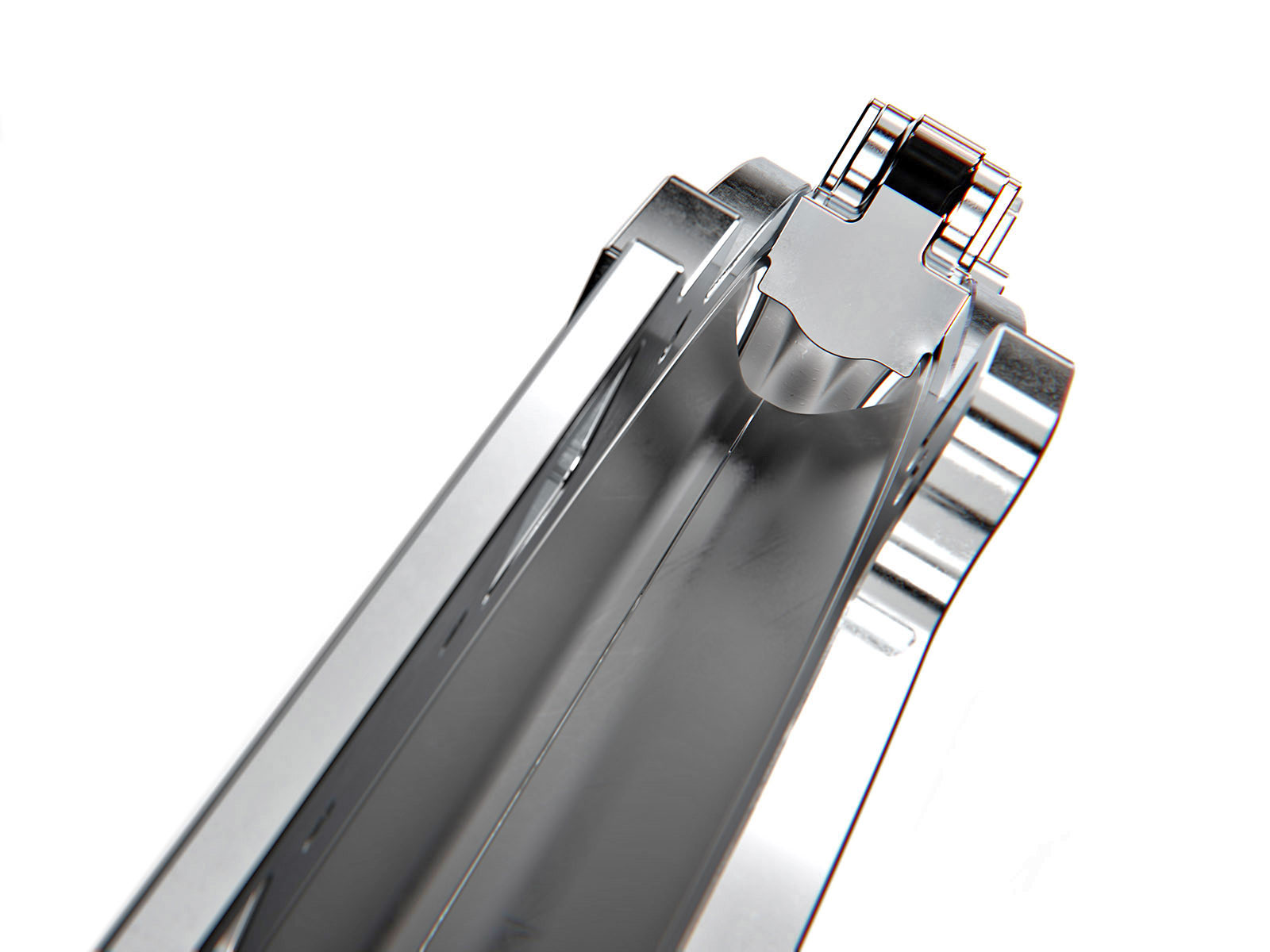

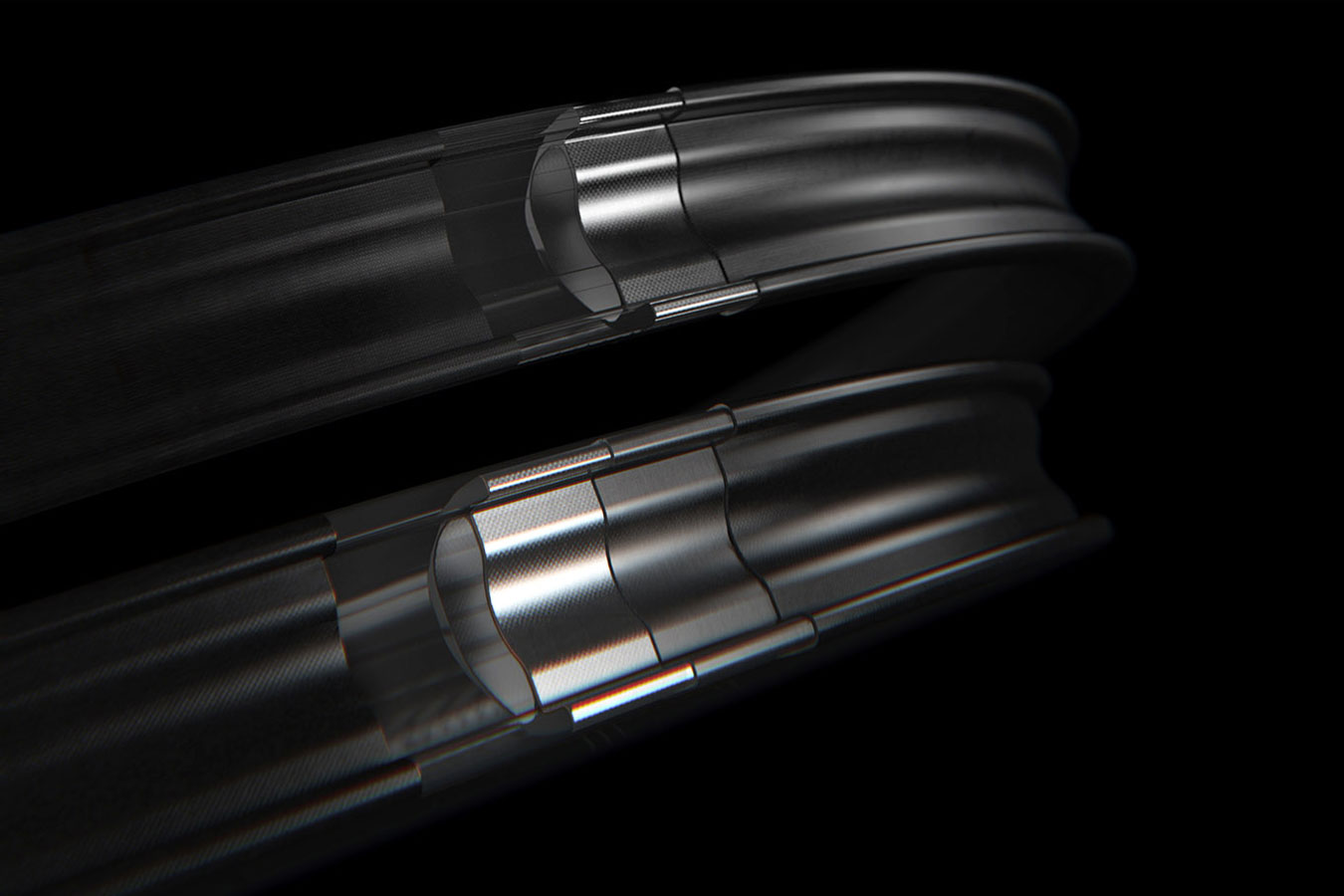

The new rims use a mechanical mold where DT places continuous fiber layers directly into the mold (instead of the smaller pieces that are conventionally laid up together and then placed into a mold), ensuring more consistent placement, less overlap, and less need for extra material as an additional safety factor to account for slippage within the layup. More consistency, combined with longer uninterrupted fibers, generally means greater lifetime durability and the ability to achieve the same strength at a lighter weight.

Molded from the outside surface layer of the rim first, and working inward step-by-step, DT is able to highly compress each layer into the one before it. That maximizes uniformity, pressing air bubbles and extra resin out for a more consistent finished carbon product.

We don’t actually know for sure. But DT’s visuals look like fibers are wound around the inside of two half-rim negative molds, while some rotating inner element presses the material outward, kind of like how a mandrel presses out to shape a tube from the inside?

It’s unclear how the inner rim bed is formed, perhaps separately in a similar process, then joined to the outer rim walls and beads?

Carbon Shield extra protection layers

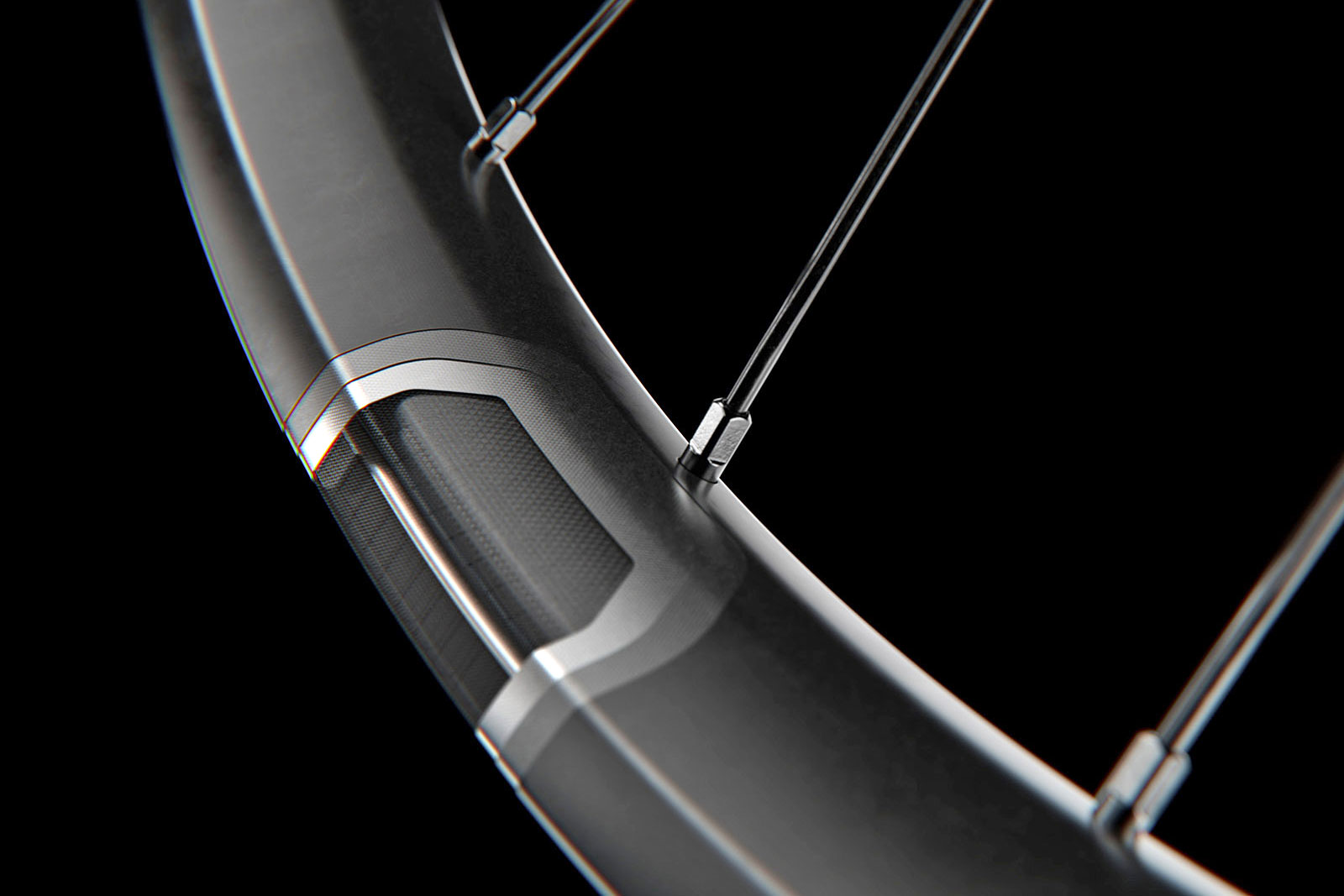

Then, once the complete mountain bike rim is formed, DT Swiss adds one or more extra layers of continuous carbon from the outside of one bead hook, across the rim well, to the outside of the other bead. This additional long, uninterrupted fiber Carbon Shield delivers extra impact protection, further preventing hard hits from wearing the bond between carbon layers.

All of the new DT Swiss 1200 wheels feature Carbon Shield tech, with the more aggressive disciplines getting more layers for a tougher shield.

Finishing and checking

A key point highlighting the precise construction is a new polished mold surface, so the rim needs no filler, paint, or clearcoat out of the mold. Just raw matte out-of-the-mold finish that even saves weight.

DT also says they have another patent pending on a “layer-by-layer nondestructive inspection” process that lets them conduct quality control on every single rim. To ensure that the product meets exacting trail-ready standards, every rim is completely scanned (somehow), ensuring that every DT Swiss 1200 series mountain bike rim is “100% fault-free” before it gets built into a wheelset.

Build specs

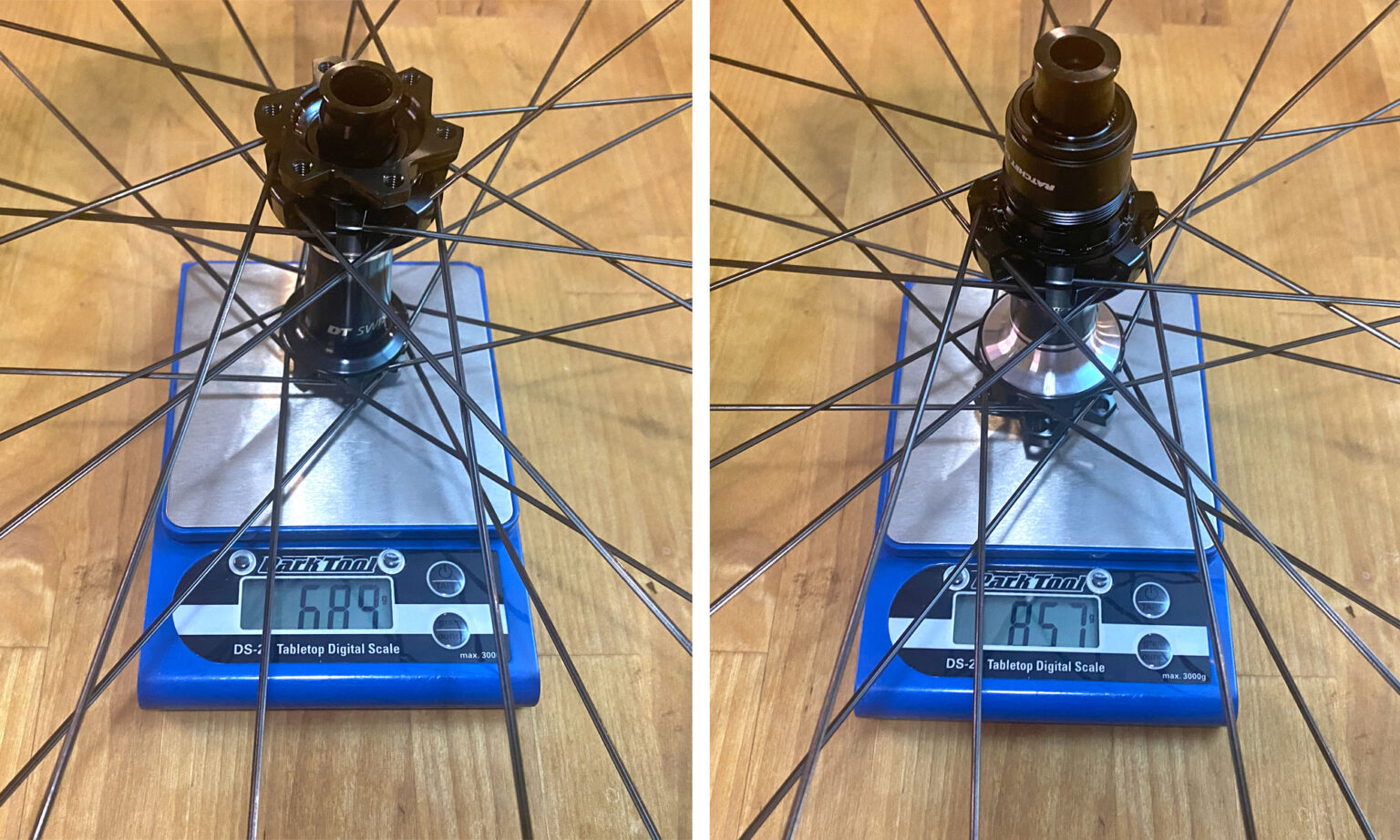

The three DT Swiss 1200 wheels feature front- & rear-specific carbon rims. Lighter up front for ‘agility’ and tougher rear rim for enhanced durability. DT builds them then on new 180 hubs with fast 54T Ratchet EXP or faster 90T DEG internals. And they fit them with SINC ceramic bearings. Plus. DT laces them with their new premium multi-butted & fluted RevoLite spokes.

The light eMTB HXC wheels get the same tough rim front & back, an ebike-specific hubset with the oversized 42T Ratchet EXP, and ebike-specific CompLite Hybrid spoke spec.

XMC 1200: First Impressions

We’ve only had the new DT Swiss XMC 1200 carbon wheels for a few weeks. And I’ve started riding them on my all-mountain/enduro hardtail and separately for a spin on a carbon full-suspension trail bike. First rides suggest a lightweight wheelset that is laterally stiff but doesn’t seem that stiff vertically. That translates to an on-trail feel of snappy acceleration, precision tracking through tech sections and high-speed corners, but not shaking you up through rock gardens and over roots & ruts.

That backs up some XC race teams we’d spoken with that described the new XRC wheels as much faster for XC racing because they are apparently much more flexible vertically. They describe wheels that flex when hitting sharp-edged rocks & roots on technical XC courses, maintaining traction – especially up techy climbs, feeling reduced rolling resistance, and reducing the occurrence of pinch flats.

That all sounds quite good. And I’m psyched to see if the all-mountain XMC 1200 wheels will translate that to more technical train riding.

DT Swiss 1200 wheels – Pricing, availability, and options

DT Swiss offers 4 total wheelsets in the newly revamped 1200 carbon wheel lineup.

They all feature a 30mm internal, hookless tubeless bead. And pricing is the same, no matter the discipline: $2912 / 2500€.

You just have to pick the 1303g DT Swiss XRC 1200 for cross-country? Or go for the 1495g XMC 1200 for all-mountain with EXP or DEG, the 1756g EXC for enduro. Or lastly, the 1908g HXC for the latest lightweight eMTB riding.