In addition to their obvious differences of added weight and torque, E-MTB’s get ridden a bit differently from normal mountain bikes. E-bikers climb trails at higher speeds, and can cover a more ground. Off-road E-bikes and their components suffer a whole new level of abuse, so it makes sense that certain components should be designed accordingly.

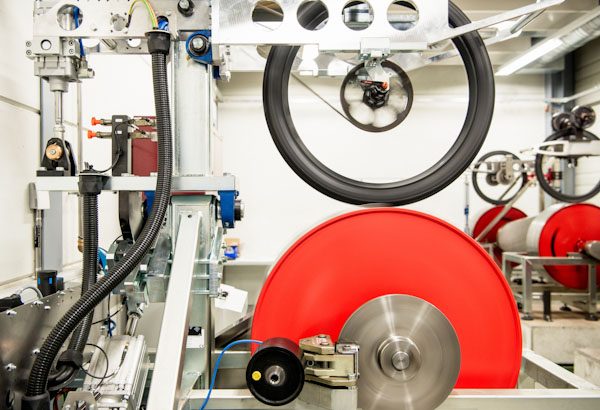

Wheels in particular suffer stresses from a motor’s torque output, and rims take an extra beating when they’re under a 60lb bike. Thus, in full support of the E-Bike movement, DT Swiss has created a new line of Hybrid wheelsets designed to offer top-notch ride performance while surviving miles upon miles of motor-assisted trail thrashing.

Check out how DT Swiss has designed their new rims, hubs, and spokes to create this E-MTB specific Hybrid wheel system…

With torque and added bike weight as their primary concerns, DT Swiss went back to the drawing board and redesigned nearly all the components for their Hybrid wheels. These new wheels achieve a weight classification of 150kg/330lbs, which the company claims as an industry first. Where their normal MTB wheels are factory tested to a minimum of 13 life cycles, DT Swiss anticipates the added mileage E-MTB riders crank out by testing their new Hybrid wheels over 27 life cycles.

Construction-wise, the Hybrid rims aren’t amazingly revolutionary, but feature thickened inner and outer walls (versus DT Swiss’ normal MTB rims). The beefier center line adds strength to the rim, and also offers higher spoke pull-out resistance so you won’t torque your rear wheel into pieces.

Although they are made of the same alloys as DT Swiss’ normal spokes, the Hybrid spokes boast a straight-pull design with reinforced heads to efficiently transfer power into forward motion. The spokes required revisions to handle extra weight and torque, and also to pair up with the new oversized Hybrid hubs.

Although they are only marginally heavier, the Hybrid spokes provide a 35% increase in tensile strength over typical MTB spokes. The new wheels use the company’s unique Pro-Lock Squorx Pro Head nipples, as they have passed all the extraneous tests put on the heavy-duty Hybrid wheelsets.

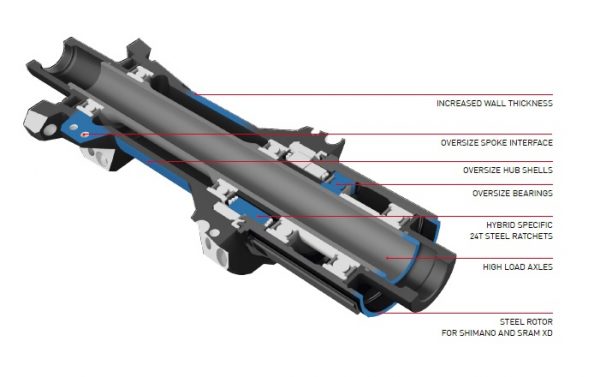

Almost every part of the Hybrid hubs has been selected or revamped for heavy duty E-thrashing as well. The large hub shells feature thickened walls and oversized spoke interfaces. The hubs spin on oversized bearings that spin around high-load axles. DT Swiss went with hardened steel 24t ratchets and steel freehub bodies to provide quick engagement and high torque load resistance. Despite achieving their 330lbs classification the hubs suffer only a minimal weight increase over a comparable MTB hub.

The Hybrid line is comprised of four different wheelsets, with options for various rim widths and 27.5” or 29” diameters. Freehub adapters are included with all models so you can run either Shimano or Sram XD cassettes. All Hybrid wheels are Boost spaced with 15x110mm front and 12x148mm rear thru-axles.

To explain the naming system, the most basic rims are the H, the HX is the mid-grade option and the HXC (C for carbon) is top of the heap. For the hubs, the lower the number the better the quality, so as we can see the 1200 hubs get paired up with the HXC rims and the 1900’s go with the H rims, etc.

The top-of-the-line HXC 1200 wheels are only offered in a 30mm width, but you can choose between 27.5 or 29” sizes. Stepping down, the HX1501, H1700 and entry level H1900 wheelsets all give you the choice of 25, 30 or 35mm widths on 27.5” rims, and a single 29”/30mm wide option.

For all prices and weights, check out DT Swiss’ website. The new Hybrid wheelsets will be available in May.