Carbon rims are already pushing the boundaries of light weight, so how do you make your wheels lighter? In many cases, you could turn your focus to the hub. Utilizing carbon fiber is usually a good way to reduce weight, but building a hub out of it? Not so easy. Because of that, most manufacturers simply use a carbon hub shell with aluminum flanges which can handle the stress of the spokes. That still leaves a lot of weight on the table though which is why ENVE invested the time into a full carbon shell.

Several years in the making, ENVE is finally ready to launch their insanely light hubs to the world which are sure to equally lighten your wallet….

In order to create a full carbon hub shell that would hold up to their torture testing in the grand tours and over 100k miles of total testing, the flange of the hubs needed special attention. Using a continuous fiber construction and molded rather than drilled spoke holes, the patented process has gotten the green light. Utilizing DT Swiss internals, the only difference in construction on the inside is bonded in drive rings rather than threaded. The DT Swiss parts allow for Shimano, Campy, and SRAM freehub bodies which are easily serviceable.

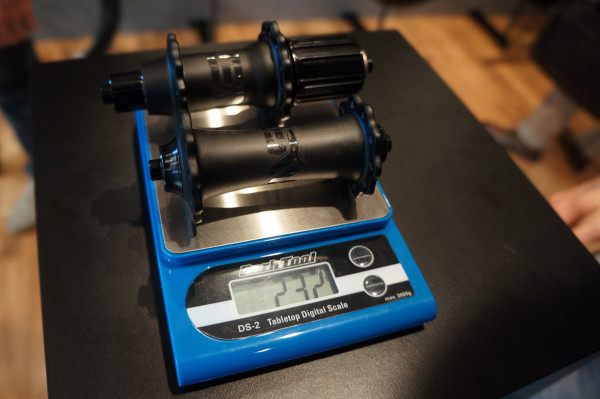

The result of those Made-in-Utah carbon shells and DT Swiss internals is a staggering weight of 232 grams for the pair. That includes the Ceramic Speed bearings as well.

Offered in hubsets in 20 F/24 R spoke counts, the hubs will also be available built into complete wheels with ENVE’s rims. The price of admission comes at an equally staggering $1350 for the hubs alone. At that price the wheels built with ENVE SES clinchers at $3500 or the ENVE tubies at $3300 seem like a bargain. Available soon.