“Nothing happens overnight. We took a look at how we wanted to introduce it and how we wanted to do it,” said Michael Hall, Zipp’s advanced project manager. “The 303 made sense because it’s such a popular wheel and a lot of people use it for cyclocross.”

Finally, Zipp has introduced a tubeless-ready carbon rim, and they’re starting with the 303. It replaces the disc brake 303 (the rim brake version remains non-tubeless and uses the regular rim), and it’s an entirely new design with a new carbon layup keeps weight the same as before despite growing wider and while maintaining the durability they’ve built into it over years of racing on the cobbles.

So, what’s different? The old 303 Disc “looked” like they simply took the rim brake version and laced it to disc hubs. In reality, it was a disc-specific rim that just happened to keep the woven carbon area where the brake track normally sits. Why? Because woven carbon is very good at impact resistance, which is why they use it on a lot of their rims, even the full aero disc ones. But for this new tubeless one, they started with a 100% clean sheet and gave it a new molding process to create the tubeless rim bed with a machined bead hook. They maintained a hook because ETRTO does not recommend a hookless design for anything greater 72psi, and since this is a road wheel, they kept the bead to ensure maximum safety.

It’s still 45mm deep, but external width has grown to 29.9mm wide, up from 27mm, with a 21mm internal width that supports 25mm to 40+ mm wide tires. The dimple pattern goes all the way to the edges, with the “303” moniker molded in with them. Only the brand logo is decaled on.

A molded notch and rounded center channel are designed to both ease tire installation and ensure a good seal.

There’s no minimum recommended pressure, and one of their CX guys has been running a 32mm tire as low as 15psi.

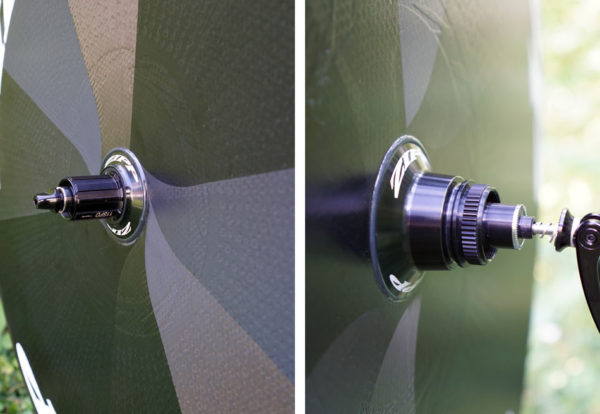

Setting it up tubeless requires tape, which comes preinstalled with a tape borrowed from SRAM’s mountain bike parts bin, along with a tubeless valve stem custom made to fit the rim bed shape. There’s no Zipp tubeless tire yet, nor is there a branded sealant or recommendation (they’ve done most of their testing with Stan’s, though).

If you’re not mounting up fat cyclocross tires, they say it’s aerodynamically optimized around 28mm tires, which match the rim width the best.

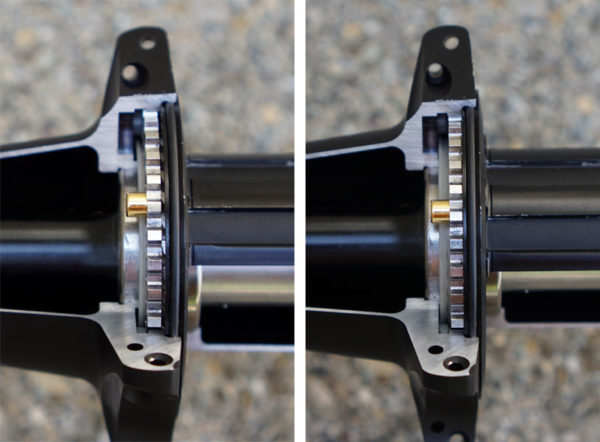

They’re built on the proven 77/177D hubs, which have swappable end caps to work with QR and thru axles. It’s also compatible with 10/11 and XD Driver freehub bodies. Claimed weights are 1645g (760g front, 885g rear), price is $2,300 / €2,400 / £2,027, available in December.

Next up is the new 202 NSW carbon clincher, preceded with a little history on their advanced project development.

Years ago, Team CSC came to Zipp and said they wanted something that could get them to the cobbles faster in the Spring Classics…faster than the wider box section alloy rims currently being used to support the wider 25-28mm tires most riders were using. So, Zipp sent a team over to test carbon rims with them and quickly found out that the then-current generation of carbon aero rims simply weren’t up to the task. So, they went back to the drawing board to create an aerodynamic wheel around those wider tires that was durable enough for Roubaix and Flanders. In 2007, the 303 came out, followed by the Firecrest clinchers in 2010.

Now, everyone wants those wider tires, so they’ve gone back to that drawing board, now tucked away inside The Nest (their black box idea lab). For the first 15 years, they were mostly focused on aerodynamic efficiency. Then came durability, followed by a more technologically advanced development process (CFD, more wind tunnel testing) to improve real world aerodynamic stability. By stability, they mean reducing the side forces placed upon the wheel in a cross wind, which can not only create drag, but also affect handling and control by moving the “center of pressure” further away from the steering axis (you want it to be as close as possible). OK, history lesson over.

The 202 NSW (Nest Speed Weaponry) expands the NSW lineup to the ultra lightweight 32mm rim depth of the 202 for their ultimate climbing wheelset. It uses a new dimpled ABLC Sawtooth aero boundary layer control that reduces high yaw drag for better crosswind stability.