Unior Tool continues to defy the industry’s move to asian production with a number of new pro team, bike shop & consumer tools all manufactured entirely in Europe. The lead of the new tool lineup is a portable workstand (& hopefully also fixed for shops) which moves away from clamping seatposts or frame. Plus there’s a new BB tool, even updated tool handles across the board…

Unior Tool Pro Road Stand – portable or fixed?

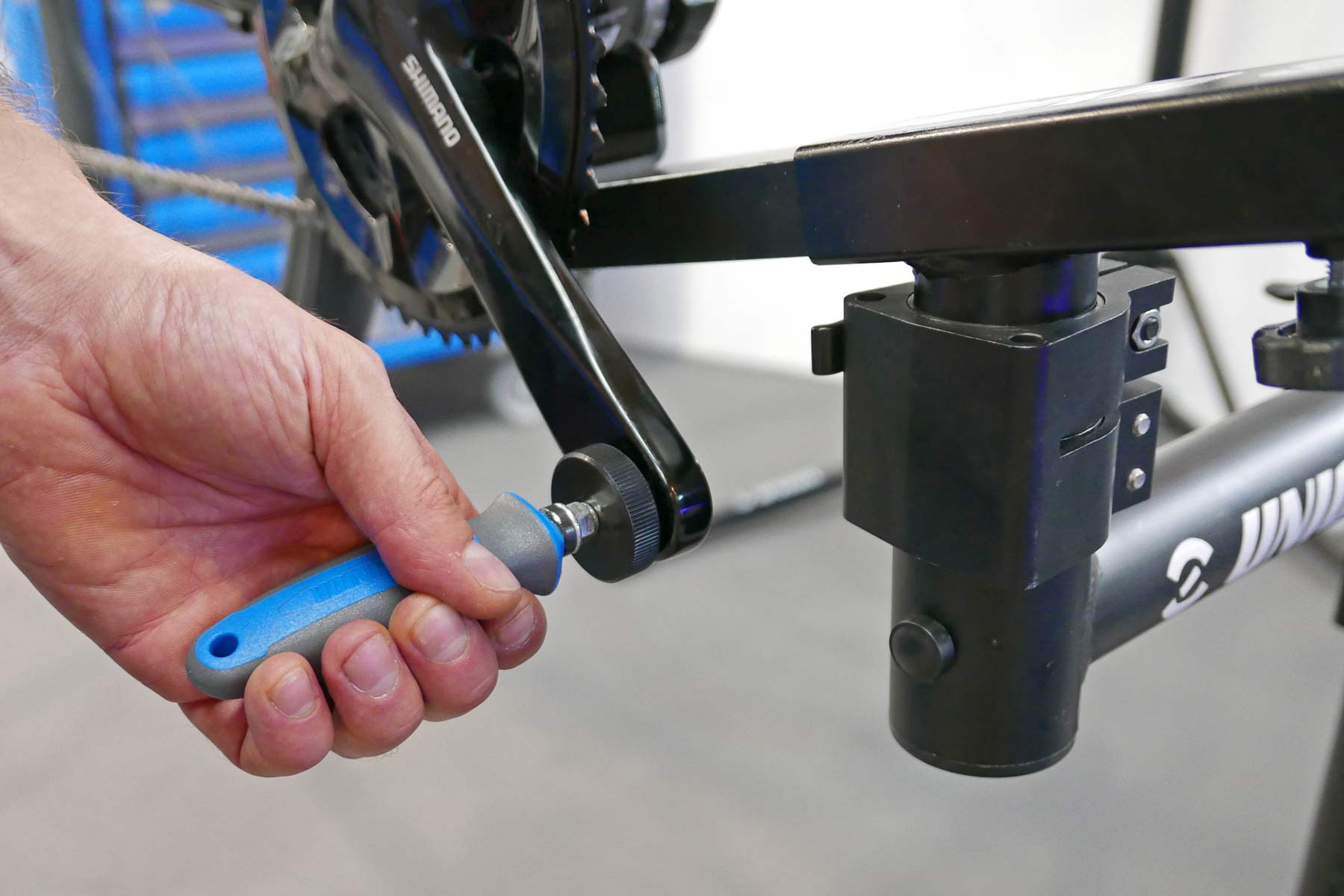

At the special request of their pro road team sponsorships Unior developed the Pro Road Stand which clamps the bike by the fork or rear drops and then supports the bike with a rubberized cradle at the bottom bracket.

In reality the general concept isn’t revolutionary in the pro peloton, but Unior’s design is rather unique in offering not just fore-aft frame adjustability around the stand’s balance point, but also up-and-down height adjustability from the ground, and the ability to spin horizontally about a central axis. But the big difference is the unique additional angled adjustability which is actually needed for the bleeding of many modern disc brake solutions.

Available now as a folding pro-level work stand, the Pro Road Stand was also shown with a prototype workshop base. Developed specifically for their sponsored teams’ Service Courses, the fixed Pro Road Stand with a heavy flat base may go into production depending on buyer demand. And in reality that’s pretty much a sure bet since bike makers have started telling dealers not to clamp frames or even seatposts, leaving only the axles. The stand does not fix the BB, instead relying on the bike’s mass to keep it stable. A set of thru-axle clamps wasn’t immediately available but will be an upgrade soon, and can be stored on the stand with the QR setup.

Precision Bottom Bracket Cup Sockets

Another simple tool, just executed well here. The tight fit of the Unior BB sockets promises an easy to use fit (with knurled grip for hand setting cups) and no marring on your bottom bracket cups. The are available for a number of threaded standards.

Pedal Genie Dummy Pedal Axle

Another tool that innovates in its execution, not its concept. Others have dummy axles for workshop use. Urior’s Pedal Genie offers both a pressed in taper plastic fit for fast and easy spinning, to a threaded alloy dummy axle for more precise fit of more complicated bike setups.

More & more tools

Unior doesn’t stop there. Their Pro Shop Clamp QR for head for workshop stands gets the new quick release 22-60mm tube size update we saw as a prototype last year.

Plus their 2 for 1 Disc tool, a caliper spreader & rotor alignment too is finally available. It is also the first to get a new double dip handle treatment that promises better ergonomics, and will be on every hand tool in 2019.

Then there are new, simple to manage electronic torque wrenches in 1/4″ 1-20Nm & 1/2″ 4.2-85Nm varieties.

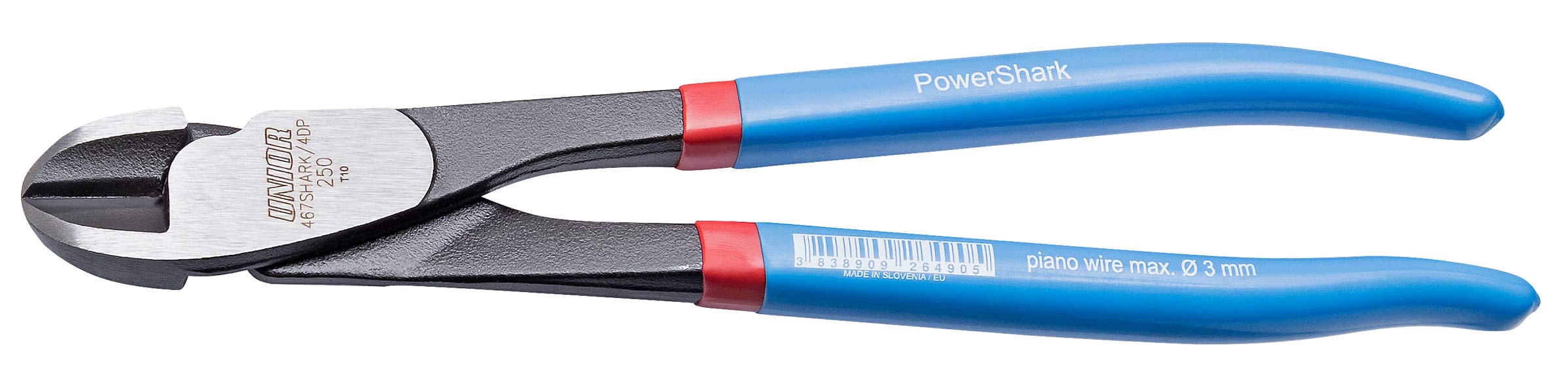

A new set of Cable Housing Cutters get a new more durable, sharper black finish, plus a revised end crimp section in the handle. And for when you need to cut wires, opt for the PowerShark angle wire cutters. And for when you need to remember how to adjust you ride…

Prototype derailleur alignment gauge

The prototype Foldable Derailleur Hanger Alignment Gauge features a solid, precision telescoping design to make hanger adjustment easy. It fits 16-29” wheels and will ideally be available soon. The prototype we saw was just one day out of the forge, so we’ll update when we know more.

The prototype Foldable Derailleur Hanger Alignment Gauge features a solid, precision telescoping design to make hanger adjustment easy. It fits 16-29” wheels and will ideally be available soon. The prototype we saw was just one day out of the forge, so we’ll update when we know more.

For the most part, all the new tools are in production now, with availability slated for at latest August 2018. The couple of prototype items above are a bit further out.

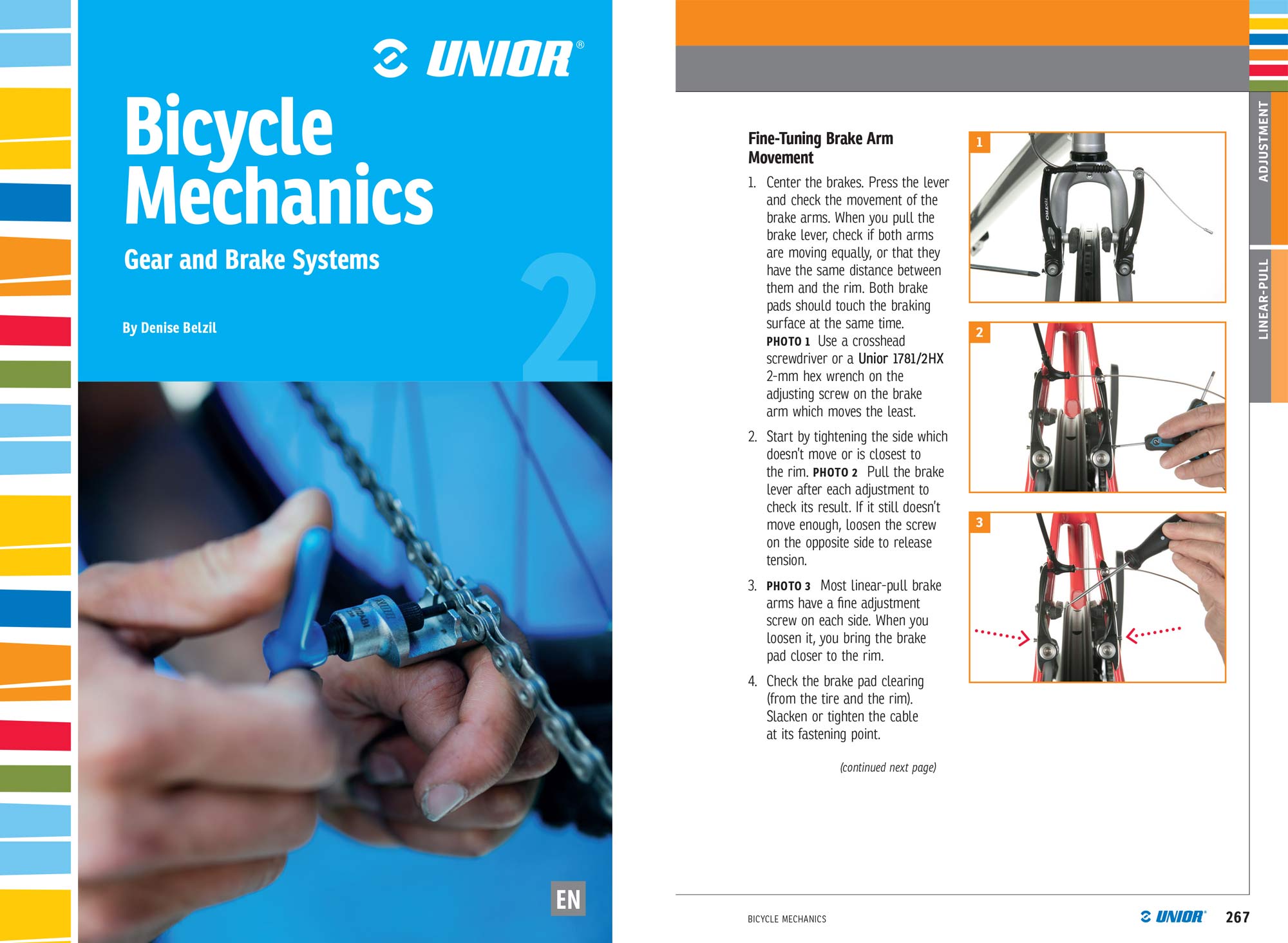

Bicycle Mechanics Volume II – Gear & Brake Systems

One last parting shot, Unior has continued their partnership with Canadian author and expert mechanic Denise Belzil to detail how-to instructions for bike maintenance & regular work. Volume I covered hubs, BBs & headsets. Volume II covers gear and brake systems.