Did you ever imagine that there was a real risk, when you pumped up your road tubeless setup to your tire’s max PSI, that you could delaminate your carbon rim? Well, ENVE explains how an imperfect (and quite common) tubeless setup can actually pressurize the internal cavity of your rim, exposing it to high internal pressures that rims, especially lightweight carbon rims, were never designed to handle. So they made these unique little Pressure Relief Valve Nuts as a simple, low-cost solution to safeguard your wheels.

And not just their wheels, they’ll work on any brand rims. Because the problem isn’t specific to their rims. Actually, it’s not a problem with any brands’ rims per se, it’s all about the set up.

Why would you need to release pressure?

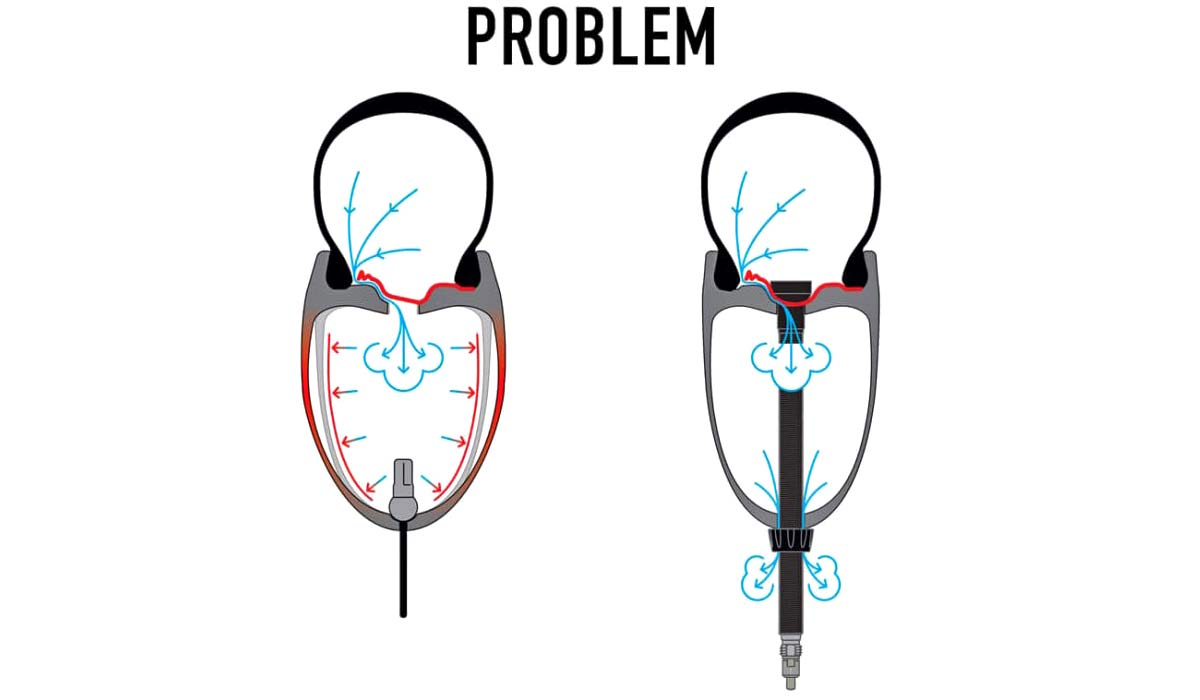

The general thinking behind ENVE’s Pressure Relief Valve Nut is that any failure in the tubeless setup of your rim can allow air pressure to build up in the inner chamber of the rim. That will happen if there is an imperfect seal between the rim bed & tubeless rim tape, like if a tight tire scrapes the tape off the rim shoulder (or you use tape too narrow for your rim). Basically any damage the tape while installing a tire can allow air to pass through. An imperfect seal between the rubber gasket end of the tubeless valve stem & the valve hole can have the same result, and those holes are often just poked into the tape with the valve itself.

Our first thought would be that if there isn’t a good seal with the tire-to-tape or the valve-to-rim, your tubeless setup wouldn’t hold air anyway. I’ve experienced this more than once.

c. ENVE

c. ENVEBut since many carbon rims have an especially tight connection between nipple & rim, and often no other opening in the rim (some rims have drain holes that would probably alleviate the issue), if pressure escapes from the tire through the rim bed, it can become trapped inside the rim. Then when you pump that new road tubeless tire to its maximum pressure over 100psi, the rim can become internally pressurized at that same pressure. And ENVE says that is something rim producers have not designed their products to withstand.

Why is this coming to light now?

First, at tubeless mountain bike tire pressures, the potential pressure inside a rim was relatively low and unlikely to cause any damage. But now as more road riders adopt tubeless, and more DIY setups are installed, there just is greater risk of pressurizing rims. And since we all keep demanding lighter road tubeless rims, especially in deeper carbon wheels, rim producers have been pushing the envelope of the material. ENVE even says that most standard weep holes drilled in the side of road rims aren’t big enough to let air out quickly enough, and can still result in dangerous internal pressures.

So when you expose a lightweight rim to high internal pressures that it wasn’t designed to handle, you open up the possibility of delaminating the carbon structure of the rim. In extreme cases, you can separate the rim sidewall from the tire bed (many carbon rims are to some degree molded in multiple parts) or even create internal damage not visible from the outside while still weakening the rim.

What is ENVE’s solution?

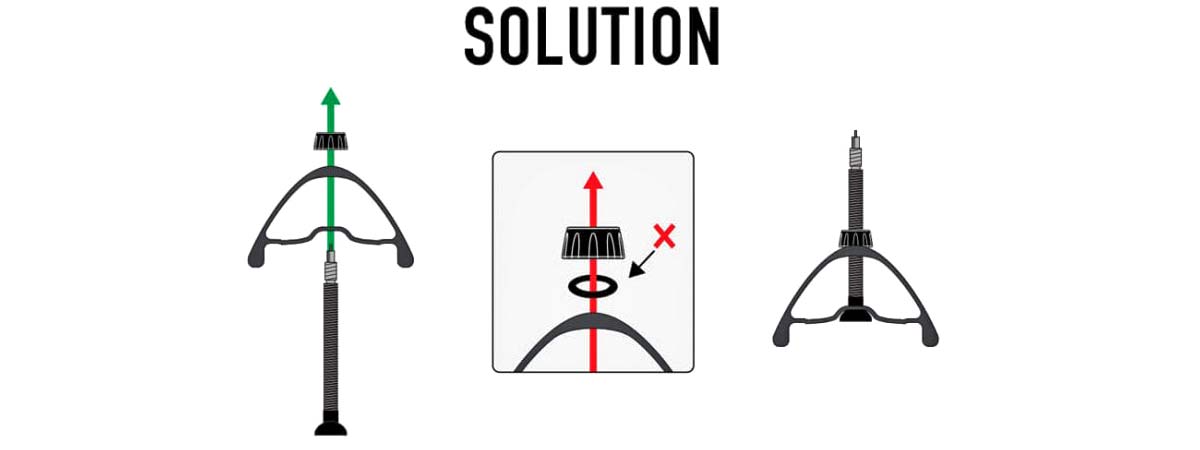

Looking to solve the problem, Enve developed a safer tubeless valve and locknut that ditches the O-ring & airtight seal we are used to. Four fluted openings in the inner threads of the nut provide additional air gaps around the valve stem so air can escape the rim cavity if there is a problem with your tubeless setup. It may sound like the problem is air leaking around your valve, but tightening the valve down will still allow the air to escape, which is a sign you may need to redo your tubeless tape.

The product is a simple $5 (each) fluted alloy valve nut. ENVE recommends it for all of their top-end SES carbon tubeless wheelsets, and it can protect pretty much any lightweight road tubeless wheelset from any other manufacturer, too. It’s hard to argue with spending ten bucks to safeguard your multi-thousand dollar wheelset.

Learn more at ENVE.com.