ENVE has debuted a new line of performance aluminum road bike hubs that follow a similar design philosophy as their recent carbon hubs. At almost half the price of the carbon versions the ENVE Alloy Road Hubs lace their proprietary hub tech into more affordable carbon wheelsets for road and gravel riding in both rim brake & disc brake variants, or are available on their own for custom wheel builds.

ENVE Alloy Road Hub – Rim Brake

ENVE is no stranger to hubs, recently introducing an updated pair of premium carbon fiber shell, rim brake road hubs. It should come as no surprise that ENVE is leaning on the expertise of their new(ish) parent company Mavic, who has decades of experience in hubs as well, and now hopes to establish themselves as a trusted hub maker both in their own wheels and the aftermarket.

According to ENVE, the new alloy hub project started with three goals:

- Optimize the hub shell & flanges for system-like wheel performance,

- Achieve best-in-class reliability with minimal maintenance requirements, and

- Maximize ride dynamics while keeping weight competitive

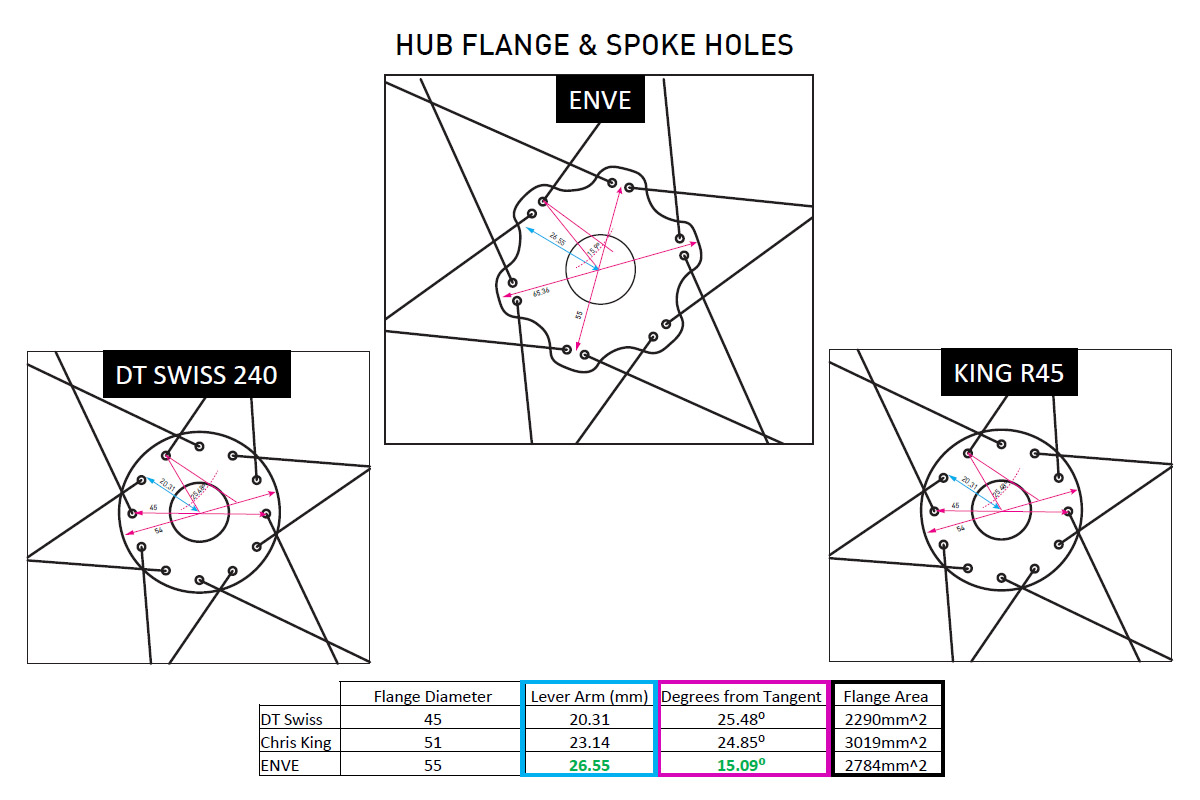

Using a similar overall lobed profile as the carbon version, the new alloy hubs feature the same paired spoke design for all models (except the front, rim brake hub). According to ENVE Chief Engineer Kevin Nelson, “The benefit of this design is that the paired spoke hole pattern of the hub flange allows us to remove more material from the flange, saving weight, while at the same time achieving bracing angles that improve efficiency and ride feel.” This allows for what ENVE calls “Virtual 3X Lacing”, with optimized spoke angles detailed above.

This allows for what ENVE calls “Virtual 3X Lacing”, with optimized spoke angles detailed above.

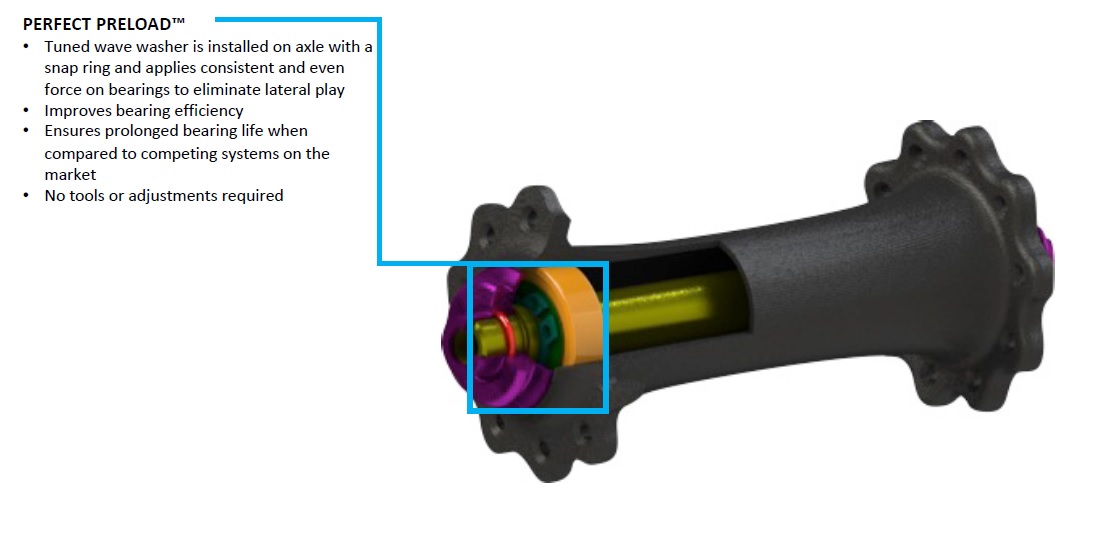

Also like the carbon hubs, the new aluminum models use ENVE’s Perfect Preload system.

This system was explained to us by ENVE VP of Product and Consumer Experience, Jake Pantone:

This system was explained to us by ENVE VP of Product and Consumer Experience, Jake Pantone:

“Generally speaking, there are two primary methods for establishing bearing pre-load, straight stack-up, or some form of adjustable pre-load mechanism. From our experience a straight stack-up design can cause premature bearing wear and fatigue if tolerances don’t line up perfectly all the time. On the other hand, our customers consistently complain about bearing play associated with adjustable pre-load mechanisms which left

unattended, can create larger problems down the road. Our solution to this problem is Perfect Pre-Load.”

Bearing preload is set by a wave washer sitting between the bearing and a snap ring installed to the axle, providing a fixed preload setting that doesn’t require adjustment.

The hubs also use the same internals and 40-tooth ratchet ring as the carbon models, with full compatibility for Shimano, Campagnolo & SRAM XDR. It even includes a removable rubber gasket that allows you to tune the volume of noise from the hub while free-wheeling. Could this be the hub to finally bring all riders together, regardless of race, gender, and freehub noise preferences?

ENVE Alloy Road Hub – Disc Brake

The disc brake version of ENVE’s alloy hubs follow all of the same key design principles as the rim brake models. They use the same wave-spring preload, paired spoke flanges, and rear hub ratchet internals.

Brake rotor compatibility follows the Centerlock standard, but each hub includes an adapter for 6-bolt rotors as well. Axle compatibility includes QR or 12mm thru-axles.

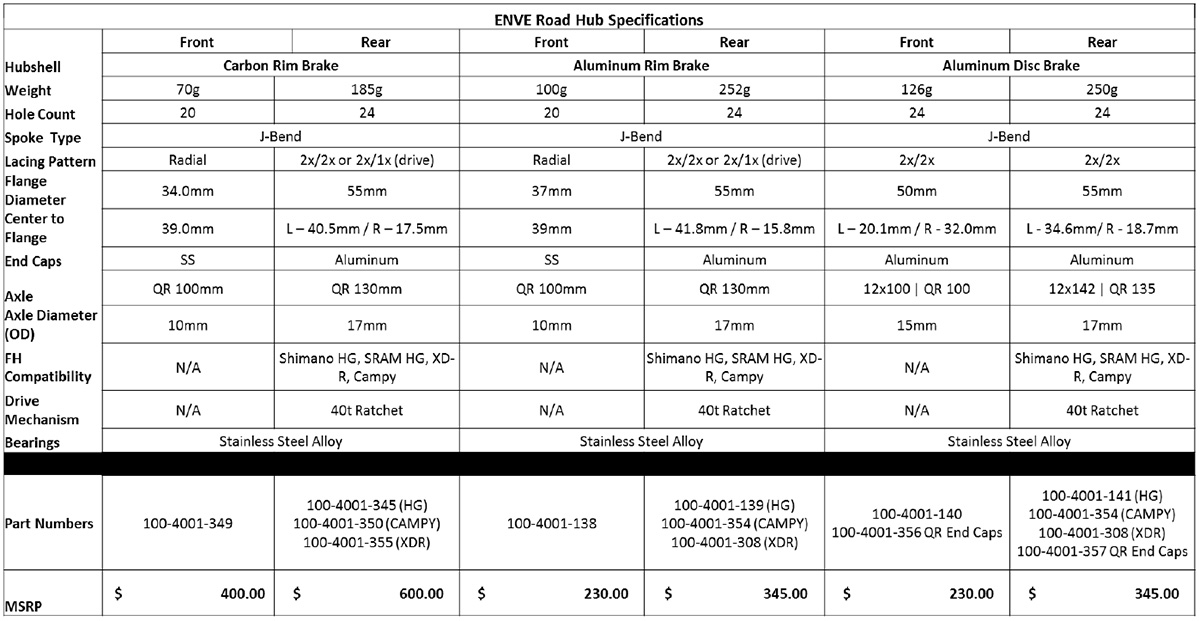

Check out full the full specs for all ENVE road hubs in the chart below.

Both rim and disc brake hub sets are available now – either in complete SES or G Series wheelsets from $2559, or as standalone aftermarket hubs for $575 per pair (44% less than their carbon hubs). They follow the ENVE 5-year warranty with Lifetime Incident Protection Program. Even though they now have a wide in-house hub offering, ENVE will continue to offer custom wheel builds with select premium hub manufacturers.

Learn more at ENVE.com.