Last month Motion Ride, the French suspension engineers who brought the wild leaf-sprung, anti-dive E18 enduro linkage fork teased an all-new Flow Evo Coil rear shock promising real shock innovation. By physically separating all oil damping from the movement of the shock piston Motion claims a level of sensitivity, performance & tunability unmatched by any other commercially available shock…

Inside the Motion Flow Evo Coil shock

Motion is still decidedly tight-lipped about their unique shock design as their patent application is still in progress, so we mostly discussed its internals based on these renderings and a 3D printed mockup. But we were curious to talk more in-depth about what is happening inside, so I sat down with design engineer & company founder Matthieu Alfano to talk about the Flow Evo Coil’s technologies and why they matter….

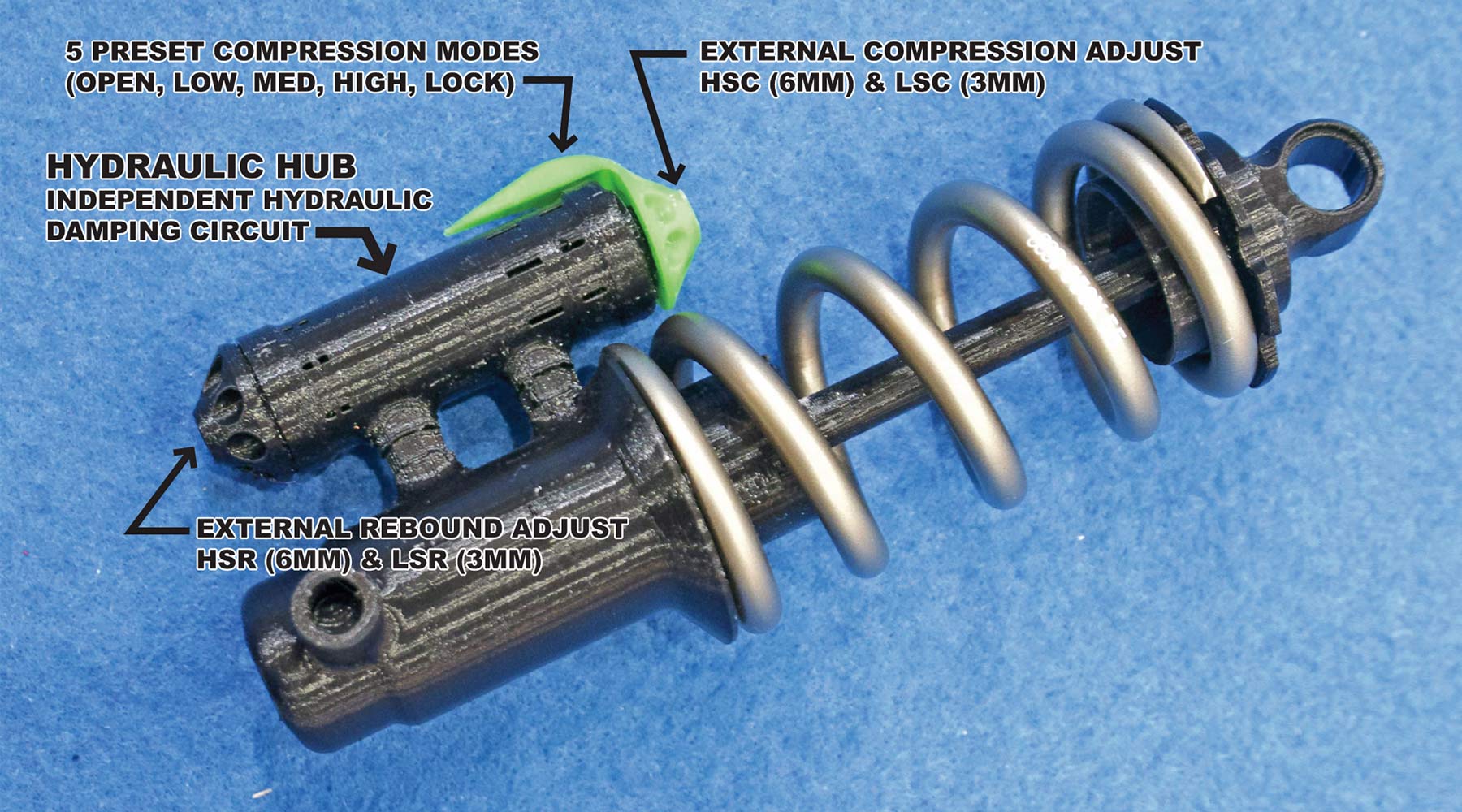

Hydraulic Hub

Optimizing hydraulic fluid flow from the core shock piston into the remote “Hydraulic Hub” allows Motion to design the hydraulic circuits for the most efficient fluid movement without having to overcome any seal friction/stiction in the piston. This also allowed Motion to create a modular design that can add additional features in the future with new Hydraulic Hubs.

The visual result is what looks like a piggyback oil reservoir layout, but is a bit more complicated than that. All of the actual hydraulic impact damping occur in that independent remote hub, offering five preset compression modes that affect both HSC & LSC (from fully open to full locked out), separate external high & low-speed compression adjustments, and high & low-speed rebound adjustment.

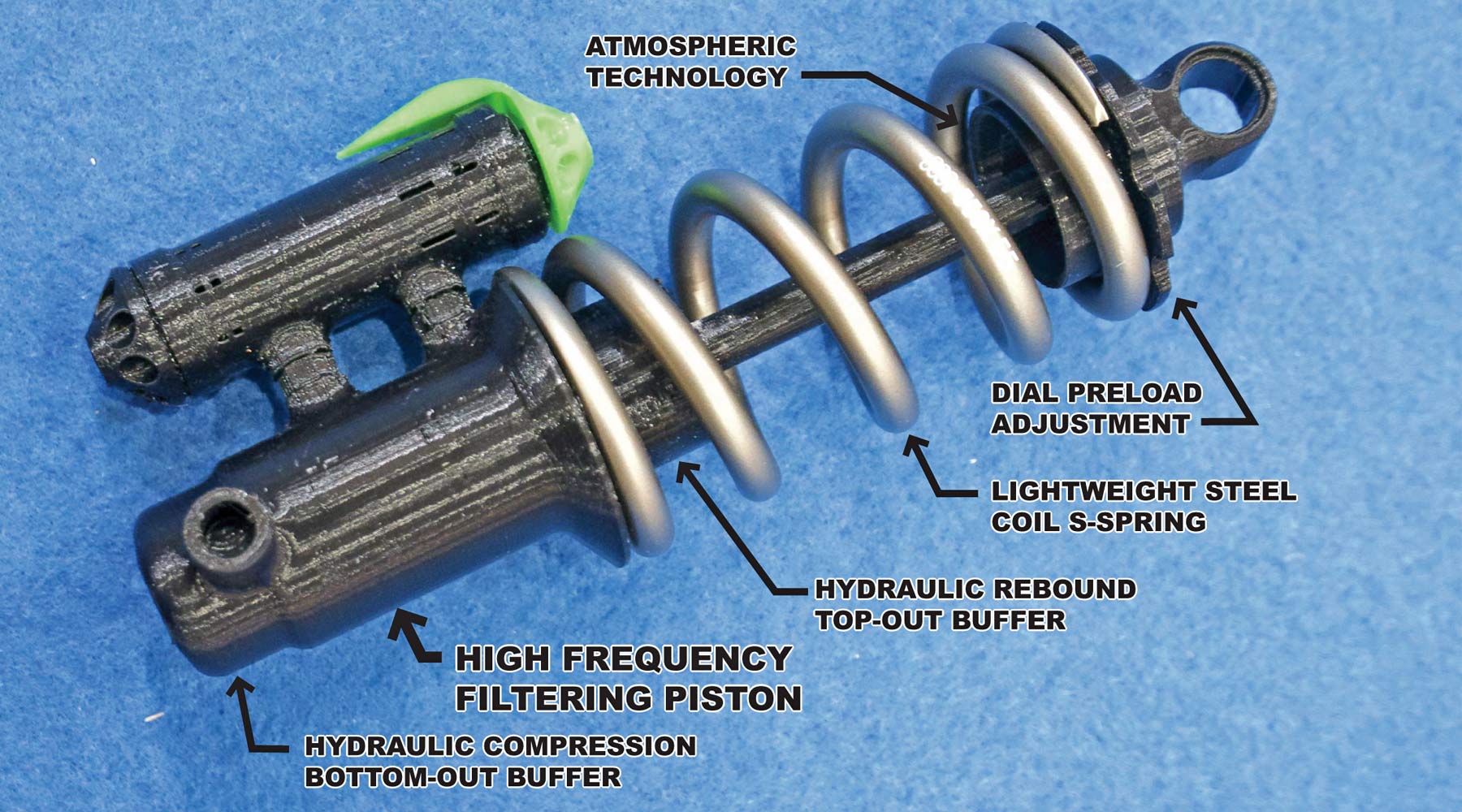

High Frequency Filtering Piston

While it isn’t something you can see from the outside, the thing that really separates the Motion Flow Evo apart from other shocks is its core “High Frequency Filtering Piston” body that Motion designed to function without initial internal pressure. This “Atmospheric technology” promises unmatched sensitivity since friction-inducing high-pressure seals are not required. Without friction in the body, the internal hydraulic fluid’s mass could be tuned to stop the transmission of the highest frequency bumps from moving fluid into the Hydraulic Hub by disconnecting the piston. Doing so is said to completely filter out these inputs for improved rider comfort & bike traction.

At either end of the piston, integrated “Hydraulic Buffers” use a separate flow of hydraulic fluid to provide end of stroke protection for the shock at both top & bottom-out. By not using a conventional rubber/plastic internal bumper, the Flow Evo shock does not sacrifice those final few millimeters of shock stroke either in compression or rebound, giving the shock 100% use of its full travel & performance allowing it to absorb more shock input energy. Also the hydraulic buffers actually damp the energy of bottom-out & top-out unlike rubber bumpers which simply rebound when hit, so the end movement of the stroke is inline with the rest of the damper’s performance.

It is a coil shock too, so the Flow Evo Coil gets a linear feel from the short & light steel coil S-spring, with dial preload adjustment. Motion says that since they were designing from the ground up, they used a shorter than normal spring for a linear shock curve, but overall shock weight on par with enduro focused piggyback air shocks – claimed shock weight of 360g + 160g for the coil.

Much of this technology is not limited to a coil shock. In fact, some of it was adapted from the atmospheric pressure Flow damper (without spring function) used in Motion’s E18 fork.

Pricing & availability

The new 990€ Motion Flow Evo Coil shock is available for preorder now in both standard or trunnion mount, in six metric sizes. Use promo code “FLOWEVOCOIL20” for a 20% pre-order discount, bringing the early bird price down to 792€ including the spring for your weight. Motion also appears to still be offering a package deal of an E18 fork & the Flow Evo Coil rear shock for 1990€ (a 700€ discount). Delivery for the new coil shock is anticipated for July 2019.