Our Wolf Tooth Components factory tour may not involve drones flying through their facility, but we get a much closer look at how they machine their parts in-house, from chainrings to dropper levers to tools and more!

And if you look closely, you’ll see a teaser of THREE new parts coming soon from the Minnesota-based brand. All three are brand new categories for them, and we even caught sketches of a possible line extension for their bottle cages! Think you can spot them? Let’s go…

Located just south of Minneapolis, Wolf Tooth Components’ HQ doubles as their factory for most of their components. Bearings and such are brought in from other vendors, and they outsource a bit (more on that below), but they machine almost everything else in-house.

If we tour following the workflow, we start at the back where raw materials are received, checked, and stocked. Different size plates and bars of aluminum sit waiting to be turned into lightweight chainrings, seatpost binders, mini tools, and more.

Hmmm, wonder what these thinner rods could be for? Are they even aluminum?

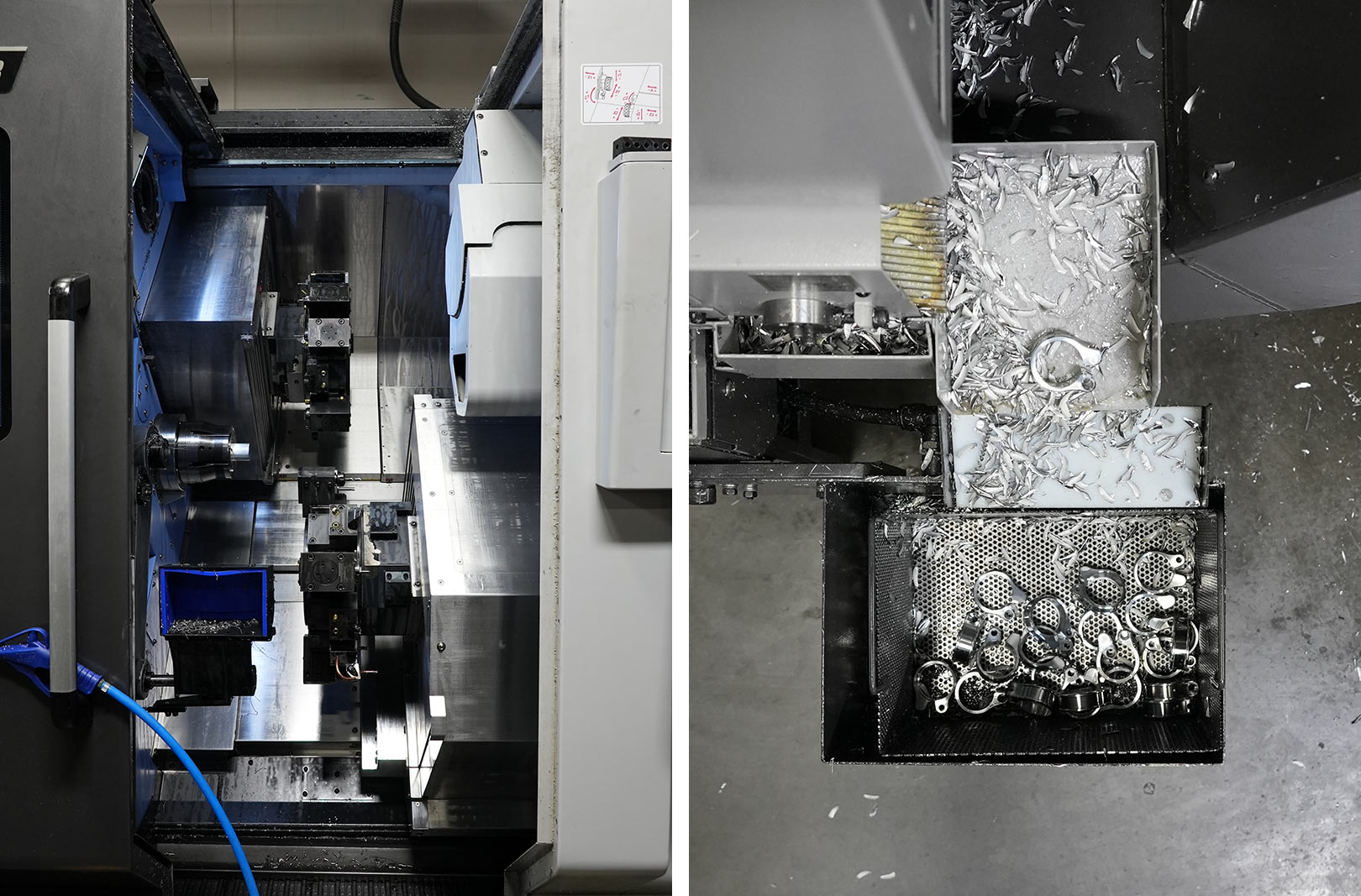

At the end of the staging area is the machine shop, full of lathes and mills, and they keep adding new machines to keep up with demand. Sometimes they use a combination of machines to finish a single part, allowing them to create intricate shapes, like on their DropStop narrow-wide chainrings’ tooth profiles.

Much of what they sell is made here, even small parts like a Centerlock disc brake rotor lock ring. These are fresh out of the machine, but they’ll be sent off for anodizing into a rainbow of colors.

Some machines run 24/7, dropping parts into a collection tray as they finish…

…with robots feeding new blanks in and pulling finished parts out as we humans sleep.

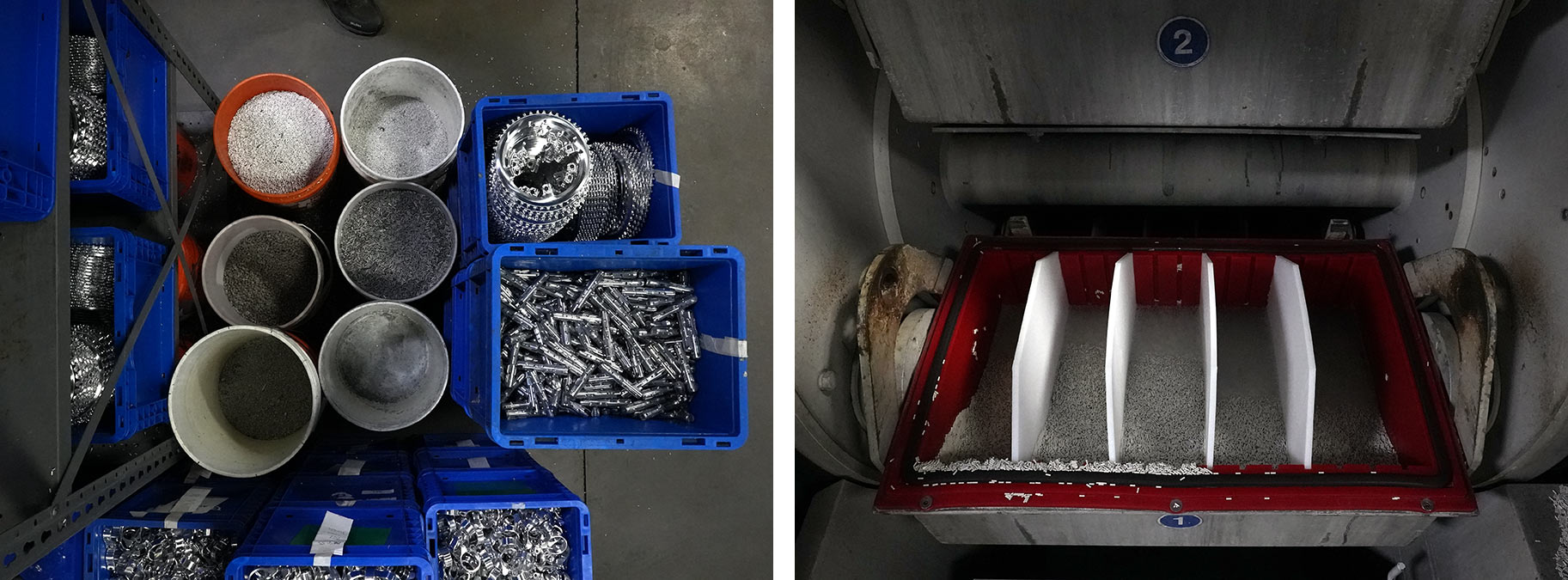

Once a part is made, they’re put into tumbling machines with various mediums to smooth any sharp, rough edges. This polishes them, too, so the anodization is nice and shiny.

The laser etching machine was the first machine they bought and lived in Mike’s basement for years before they got their own building.

In the early days, they outsourced the machining of the chainrings to two different local shops. They still use those two shops, and have only increased volume with them even as they’ve added more and more capability and capacity in-house.

Once the parts come back from anodization, which is one of the only major steps not done here, they’re organized and staged for assembly. A lot of Wolf Tooth’s assembly machines, holders, and tools are made in-house, either machined or 3D printed.

Their seatpost binders are slid onto a pin that’s pushed up by air, so it won’t jab the part if the assembler doesn’t line up the hole correctly…meaning, it won’t scratch the ano and end up in their periodic Scratch & Dent sales.

Headsets are handled similarly, with upper and lower cups of every color lying in wait for the correct bearing size. Much of these are made to order since it’s quick and easy to prep and ship, and because there are so many options and choices of colors.

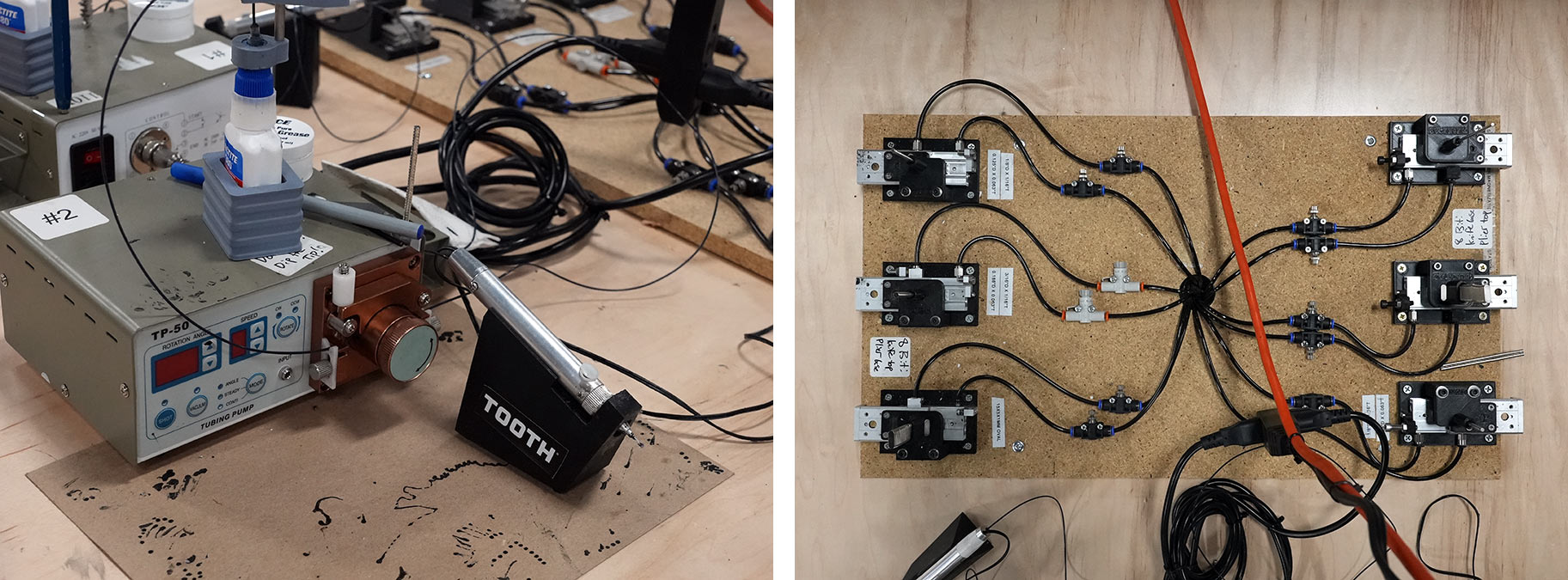

Their 8-Bit System of multitools use magnets to stay closed and/or stack together…

…so they sourced a Super Glue pump and applicator to apply a drop into the recess, then a pneumatic magnet applicator to push the correct size and shape magnet into place. It may not look fancy, but it gets the job done quickly and accurately.

Originally, they outsourced production of their Morse Cage bottle cages (which are excellent), but that very-well-known bottle cage maker simply couldn’t keep up with his own demand, so they came up with their own process and improve on the design. Now, they bend and tack their own cages right here.

Their chain lube is now bottled off-site, but this is how they got started. It’s still used if they’re low on inventory and need some extra to fulfill orders, but this workstation doesn’t see much action these days.

Wolf Tooth acquired the RedMonkey grip line a while back and now sell their foam grips in a variety of colors in multiple thicknesses.

Once everything’s prepped, assembled, and labeled, it’s sent to this guy to pack and ship. That’s most of what happens in the warehouse, but first let’s dip into the cubicles…

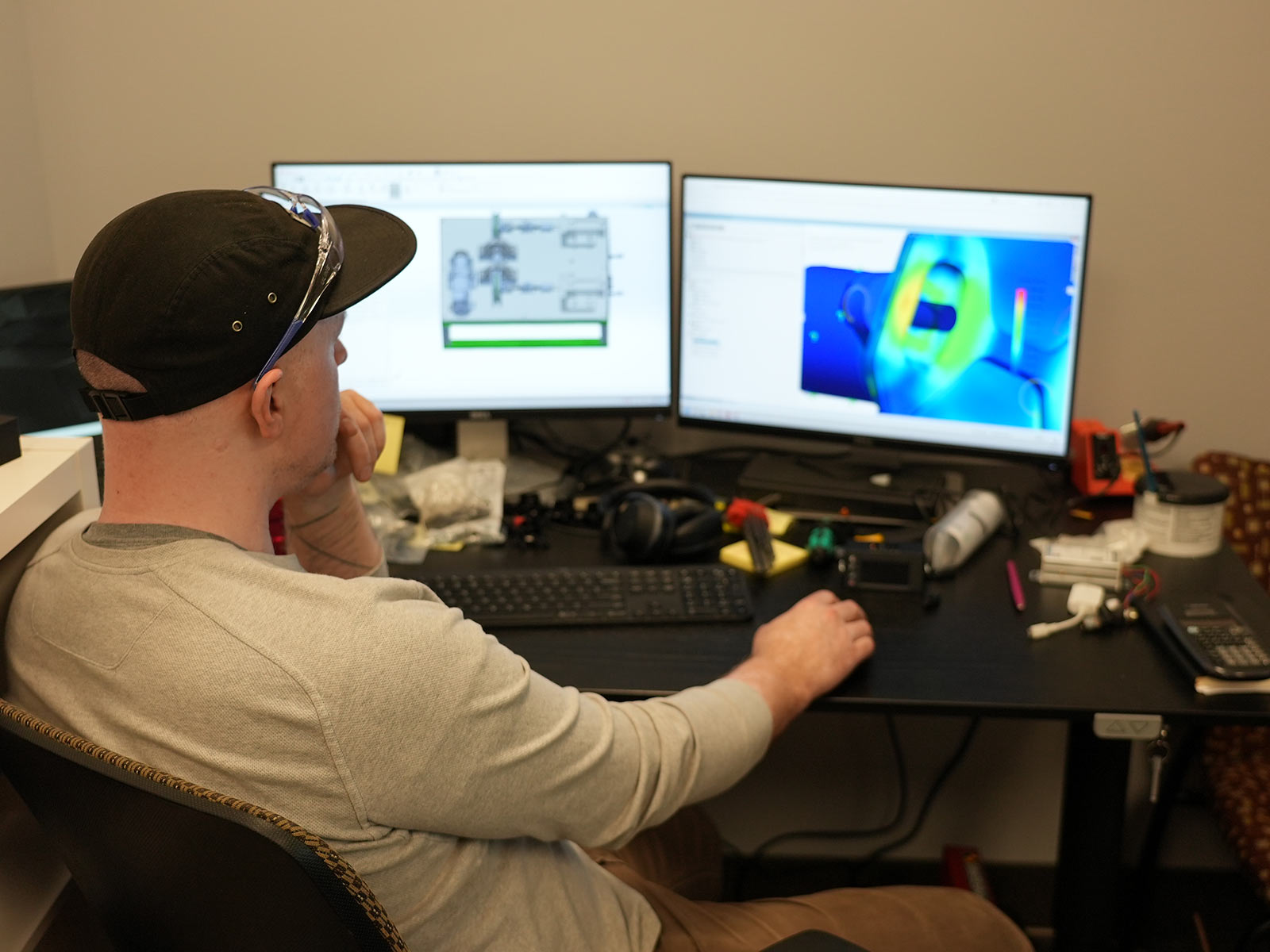

Behind closed doors is where we found a few folks designing new things…

Hmmm, wonder what they’re working on? Leave your guesses in the comments!

Otso Cycles is here, too

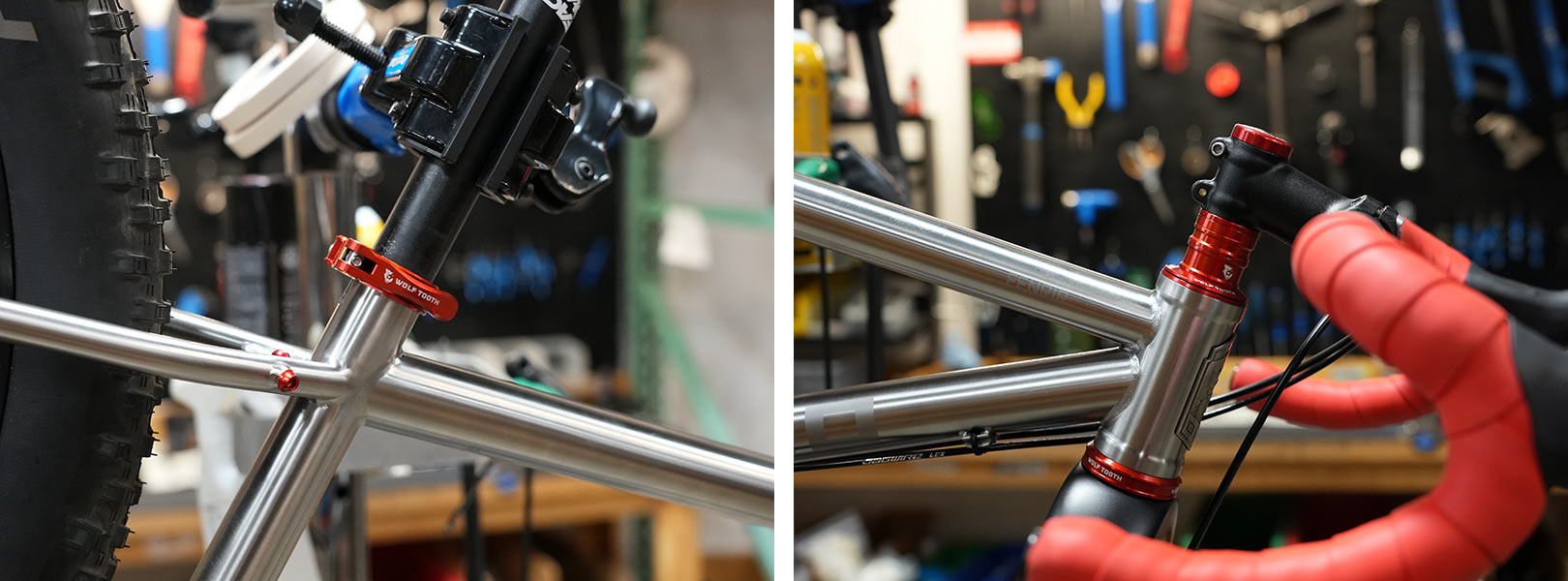

Sister brand Otso Cycles shares space here, too, where bikes are outfitted with plenty of WTC goods. A series assembly stations let them build to order and test the bikes before re-packing them to ship to the customer.

Naturally, there are plenty of Wolf Tooth Components to choose from to upgrade your ride. Even the Tuning Chip rear dropouts are designed by Wolf Tooth (and were originally made in house, but not any more), and are proprietary to their frames. They’ve recently added several new options for SRAM cranksets, including 8-bolt direct mount chainrings and the 107BCD rings shown here.

Match the headset and spacers in black…

…or whatever color you want, on whatever accessories you want.

Huge thanks to (L to R) Dan, Brendan, and Mike for showing us around (and the gravel ride and burritos that followed).