Recently in Girona for Sea Otter Europe, wheelmaker Lavelle showed us the insides of how their nearly instant engagement clutch hub works. It’s a fairly rare solution to see on premium lightweight wheels, and was unexpected inside these 5-spoke gravel race wheels.

But this is only a brief glimpse of the precision tech on offer from Lavelle. They build monocoque 5-spoke wheels for gravel and mountain bikes, but also traditionally laced carbon wheels from road to BMX. And besides the 0° clutch engagement, they also have a 7.5° option with uniquely machined 48T ratchet engagement inside. Plus, there’s a lot more interesting tech that I’ll want to dive into later – like hub cooling fins, ti axles, and wavy carbon rims.

But now we’re just getting started with Lavelle…

Lavelle 1440 POE sprag clutch hub offers 0.25° engagement

The instant engagement sprag clutch concept isn’t new – in cycling or elsewhere.

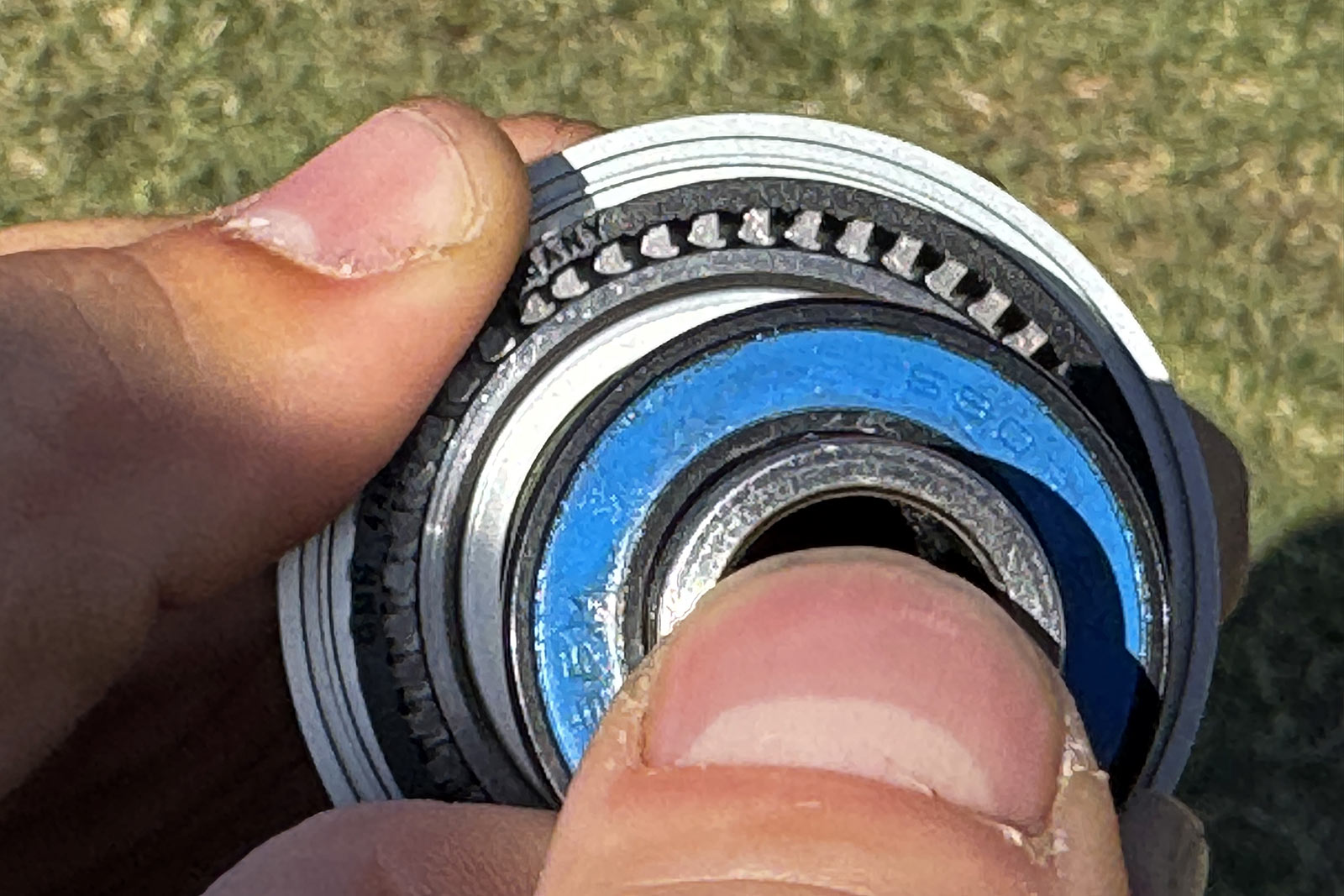

It works with a large number of little ‘sprags’ inside the hub that act like one-way pawls with rounded cams on the ends. They let the axle rotate freely in one direction with almost no drag (freewheeling). But then, when it spins in the opposite direction, they quickly rotate into place, wedging themselves between the axle & hubshell for positive engagement.

To work well, you need incredibly precise and strong inner and outer steel rings for lots of tightly-spaced steel sprags to press against. There can’t be any imperfections or deformation of any part of the system, so it tends to be difficult to manufacture and heavier than more conventional freehub solutions. We’ve been covering double-row Onyx clutch hubs since the early days of our platform. But besides their slightly lighter 1.5-row Vesper hubs shown to us as a 2017 prototype, Onyx hubs have remained relatively heavy. But the instant engagement is hard to argue with. And once a rider adapts to it, they seldom want to go back to slower engagement.

Lavelle’s solution has been to increase the diameter of a single-row sprag clutch directly over a large bearing to handle the high engagement forces needed. That also helped keep weight down, and minimized the surfaces that had to be ultra-precise.

Speaking to the actual angle of engagement, Lavelle (and Onyx) talk about the sprag clutch concept as being 0°. But in reality, the 46 sprags inside this particular hub do have to actually rotate, camming into place to engage. Lavelle calculates that rotation into place to be effectively 1440 points of engagement, for an imperceptibly small 0.25° engagement angle.

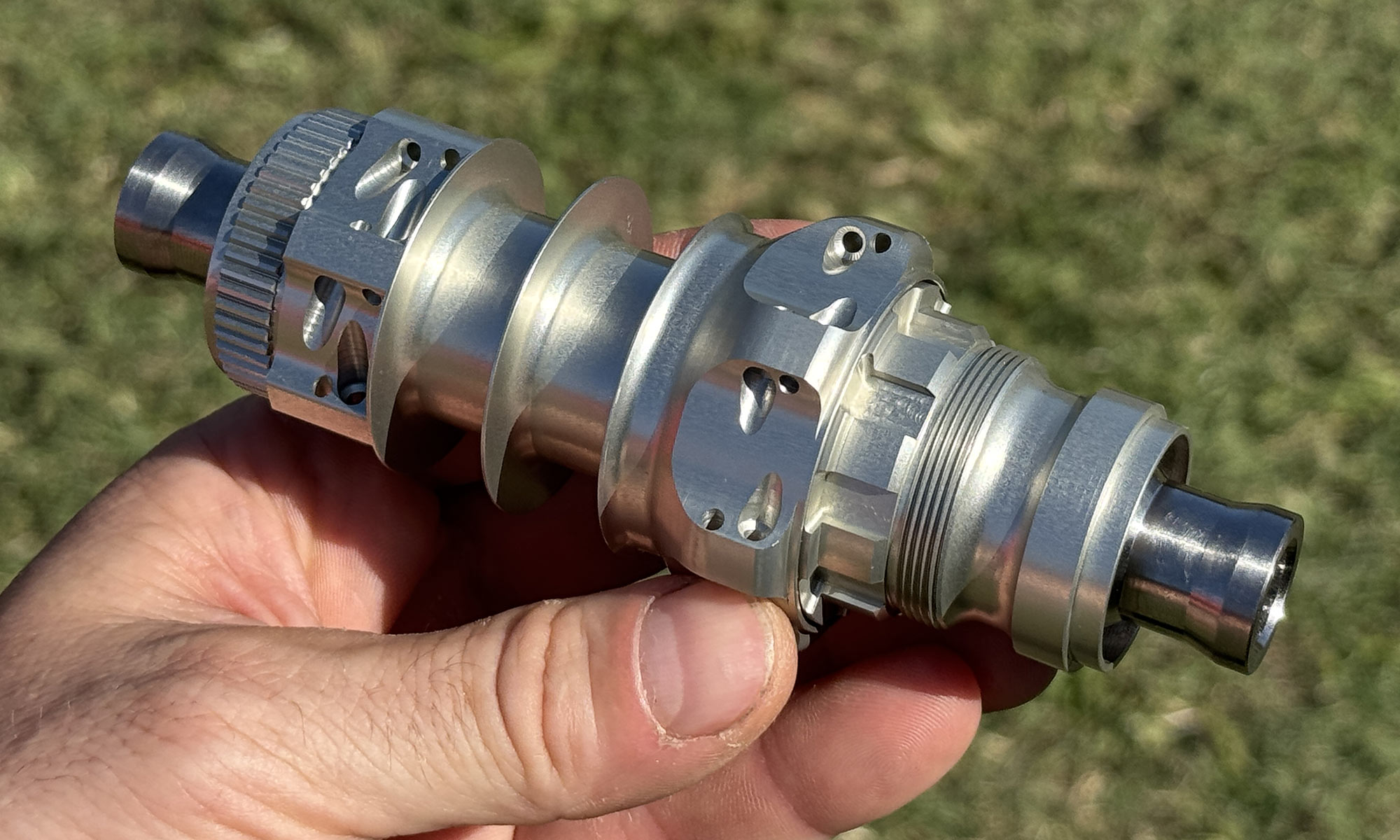

…or a 48 POE ratchet hub with 7.5° engagement

Now, maybe you don’t want or need instant engagement. Lavelle also builds a road hub with 48-tooth ratchets as well for still quick 7.5° engagement. There are a few tricks here.

First, 3-dimensionally conical tapered teeth on the ratchets ensure such perfect engagement that Lavelle can machine the ratchet directly into the alloy freehub body to save weight. They also extend the toothed interface of the ratchets out to the absolute edges of the freehub body and hubshell, maximizing surface contact area. And finally, the floating ratchet ring inside the hub is perfectly pressed against the freehub ratchet with an ultra-precise multi-turn wave spring to ensure uniform engagement all the way around.

More smart hub tech

Beyond two styles of engagement, Lavelle machines their hubs with patented external cooling fins to increase hub shell surface area significantly (~17% depending on the hub) without adding much weight for a big boost in disc brake heat management, important for extended descending.

They also all feature stiff titanium axles, said to be 10x stronger than aluminum axles, and a 65% increase in axle stiffness. That works together with 4 sets of oversized “perfectly aligned bearings” per hub to ensure smooth running and long lifespans.

The Spanish-made hubs were originally developed to form the core of their Fireroad monocoque carbon wheels, but now Lavelle has further refined them to be built into more conventional road, gravel & mountain bike wheels. And they also offer the hubs separately as an 830€ hubset to lace into your own custom wheel builds.

hub weights (claimed):

- centerlock straightpull road/gravel: front 110g, gravel clutch rear 330g, road ratchet rear 222g

- 6-bolt J-bend mountain/enduro/DH: front 149g, MTB clutch rear 420g

Lavelle Fireroad monocoque 5-spoke carbon gravel wheels

The 5-spoke carbon gravel wheels seem to be have been Lavelle’s origins, and it’s where they are refining innovation. These wheels feature a 25mm hookless internal width, measure 32mm wide external and are 40mm deep between the spokes. Lavelle builds them with a custom carbon layup tailored to each rider’s weight and riding style in Galicia, Spain. And they typically feature Lavelle’s ultra-fast-engaging clutch hubs. But you can also get a set now ready for a Classified Powershift 2-speed internally geared rear hub, too.

The standard wheelset sells for 2989€ with the instant clutch hub. Weight is generally around 1600g for the set (Lavelle claims 1060g for the carbon rim & spoke elements), including the slightly heavier 0.25° engagement clutch hub internals and non-round hub shells bonded into the carbon body. That is quite a lot compared to conventional lightweight gravel wheels.

But Lavelle claims their stiffness, aerodynamics, instant-engagement, and the impact durability of the 3.5mm wide beads more than makes up for it.

Lavelle’s engineer let me take a spin on his own gravel bike kitted out with these made-in-Spain 5-spoke carbon Fireroad wheels and weight wasn’t at all what I noticed. It was the effectively instant 0° hub engagement that immediately grabbed my attention.

It’s almost an unreal sensation for there to be an instant response from your pedals to the tires on the ground after coasting silently. But I can certainly see how you could come to love the direct feel while riding, especially over irregular terrain.

Many more Lavelle wheel builds options, too

Beyond the 5-spoke gravel & all-mountain wheels and those unique hubs, Lavelle also builds plenty of almost conventional wheels. These range from 2400€ to 3100€ depending on which hubs and rims you choose. But, there are conventional 23.5mm internal aero road shapes in 50 or 60mm depths, as light as 1200g. More interestingly wavy all-road wheels in 50 or 65mm depths with ratchet hubs and 25mm internal width, from 1330g. 32mm internal gravel wheels from 1370g. And even enduro and World Cup-proven DH wheels with variable rim widths and instant clutch hubs.

The one unifying principle is that the carbon is all laid up in Spain, the hubs are all machined in Spain, and wheels are all laced in Spain. Everything is custom-built-to-order, so lead times are around 5 weeks from settling your order.