After hinting at the potential for individual rider customization with their first 3D-printed Adaptive saddles, Fizik One-to-One finally delivers that full custom saddle fit. Powered by proven GebioMized saddle pressure mapping, the true innovation is just how easy Fizik has made the custom fitting process. Developed to be simple and fast, Fizik will measure you on your bike, then custom print a saddle to meet your specific support needs. It’s not cheap, but it’s also not that expensive – as little as 15% more than the cost of their previous top-tier Adaptive saddle.

We were intrigued. So I got fitted. I got a custom saddle made. And I’ve been riding it for the past 2 months. And the custom fit really does deliver on comfort.

Fizik One-To-One custom 3D-printed bicycle saddle

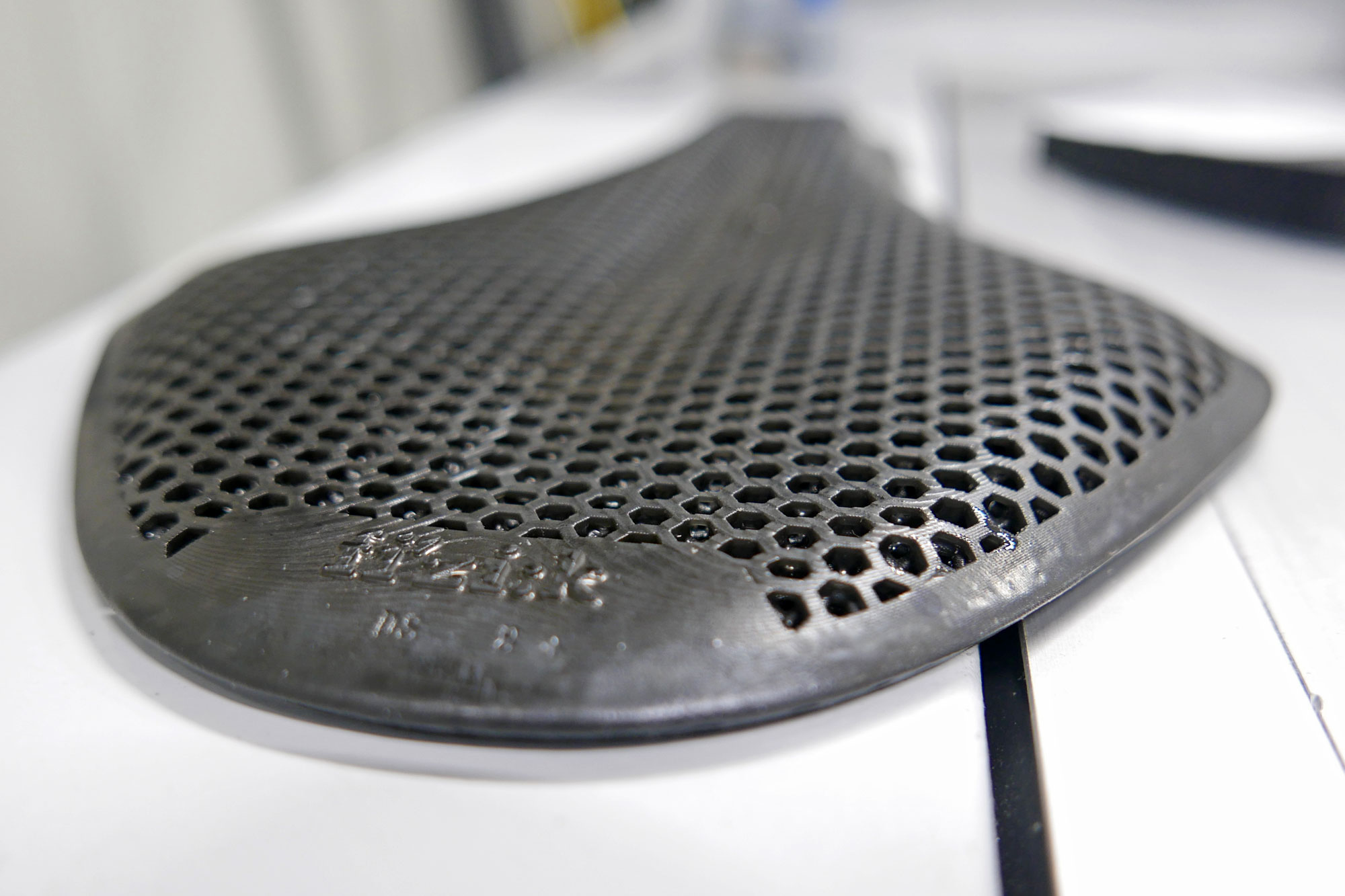

3D-printed saddle padding basically made 2 main claims from the start. 1, it meant that every separate zone of a saddle could offer a unique level of support, depending on how much was needed in each area. And 2, since the padding was printed one at a time, the only thing stopping each saddle from being custom printed for each rider was a need to collect individual rider data and design a padding structure tailored to that rider.

So first, Fizik developed their stock 3D-printed saddle line with the entire (and recently growing) Adaptive range. Its zonal cushioning offers stiffer support under the sit bones where you need it, but less resistance against soft tissue. It’s a pretty big deal, and the driver behind Specialized’s similar Mirror saddles. Both based on piles of averaged rider position data, matching rider physiology with targeted support structures in the padding.

Then, Fizik worked on individual customization.

GebioMized pressure mapping made simple

The main obstacle to making a custom fit saddle available to the masses was collecting individual rider fit data.

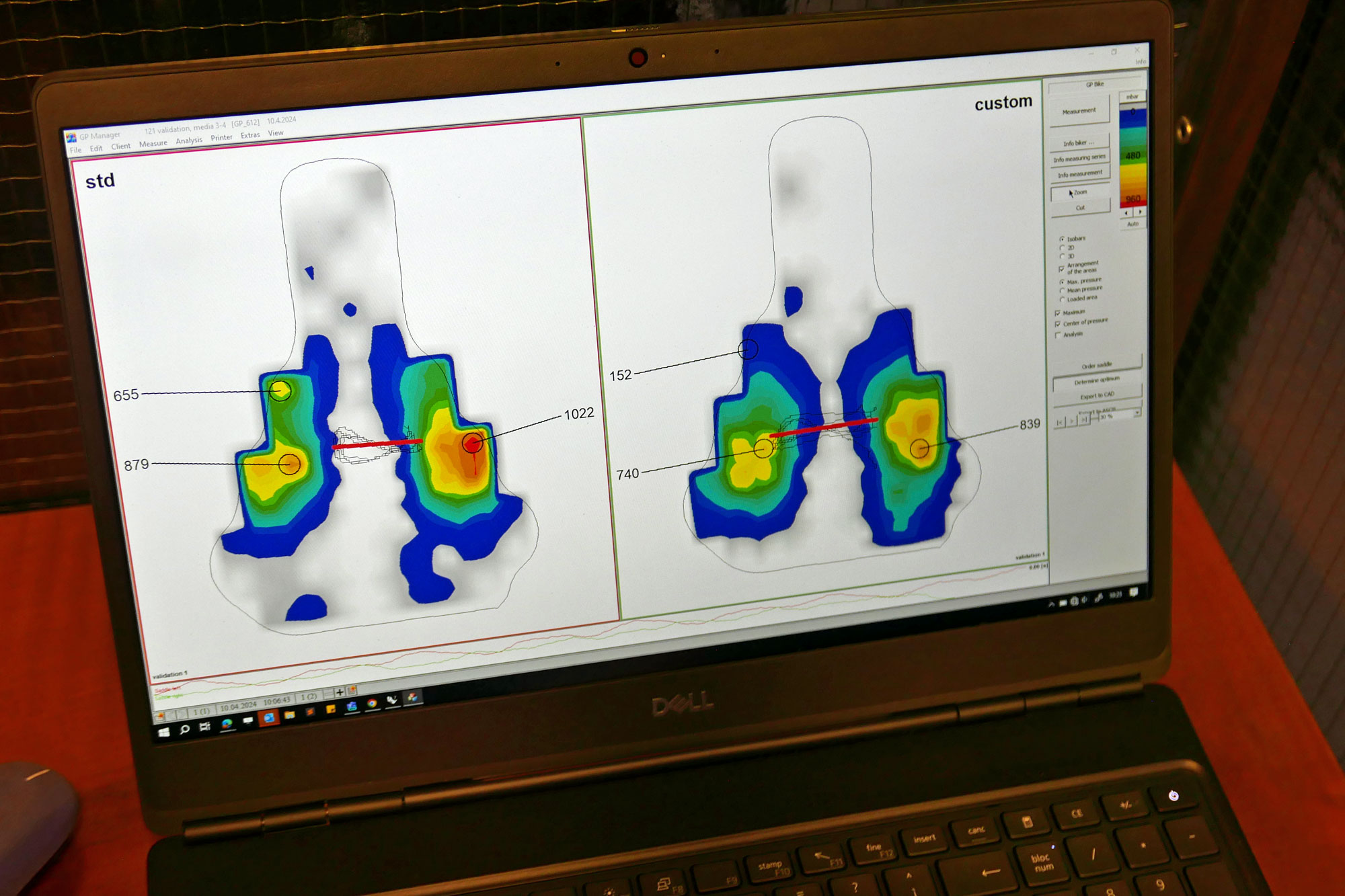

So, Fizik when to the company that was already doing it on a smaller scale. German company GebioMized has been using their unique patented pressure mapping system for 20+ years to measure real live pressures between the cyclist & saddle. A big part of that is used for refining rider position on the bike and matching the best existing saddle to the rider. I did a GebioMized pressure map fit 4 years ago, and lowered peak pressure by 20% – a real game changer. But I stuck with one of their stock saddle shapes and padding.

The trouble is/was, it was a long fit process, and required about 90 minutes with a skilled bike fitter. Not a low-cost process, and easy to add at least $200+€ to the cost of a saddle. Still totally worth it in my mind for a committed cyclist, though.

An interesting aside, Czech custom saddle maker Posedla got around the complex data collection process with a much lower-tech solution to bring custom fit 3D-printed saddles to market two years ago, at a slightly lower price.

But, Fizik worked with GebioMized and their pressure sensor tech to make the process faster and easier.

One-on-One, step-by-step

So, Fizik worked with GebioMized to create a simple smartphone app-based setup that can collect rider pressure data quickly and get you on the right saddle for customization. All you have to do is pop into one of the select Fizik fit studios with your own bike, get a fast pressure fit test in about 15 minutes or less to create a custom 3D-padding profile unique to the individual support needs of your body on your bike.

To do that, you roll your bike on to a Wahoo roller trainer that grabs your front wheel. Fizik puts their new 64-point Bluetooth pressure sensor mat on top of your current saddle. You ride for a minute in a few positions to get a general pressure map profile.

The app suggests what saddle shape and width seems most appropriate.

So then, the bike shop will swap in the standard Fizik saddle in that shape. And they rerun the pressure map test. The resulting pressure readout is then sent to Fizik, where their parametric design system adjusts their honeycomb padding structure to offer support where you need it, and soft structure where you don’t.

You pick which saddle rails you want, and then, Fizik adds it to the 3D-printer queue.

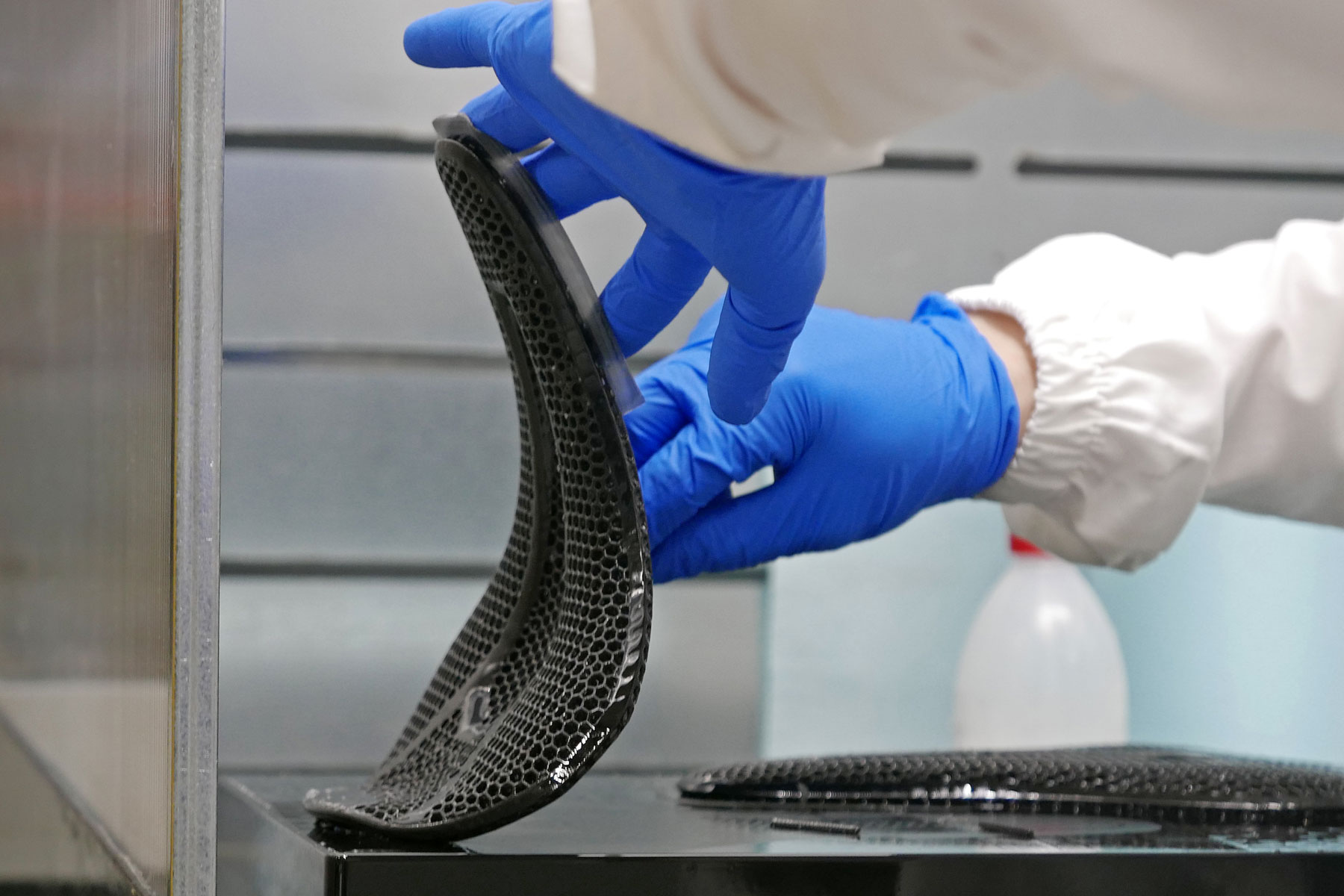

The saddle padding gets printed (which takes about half a day), and then ultimately attached to a stock shell.

And then delivered back to you to ride a full custom saddle.

So how does it feel & how does it ride?

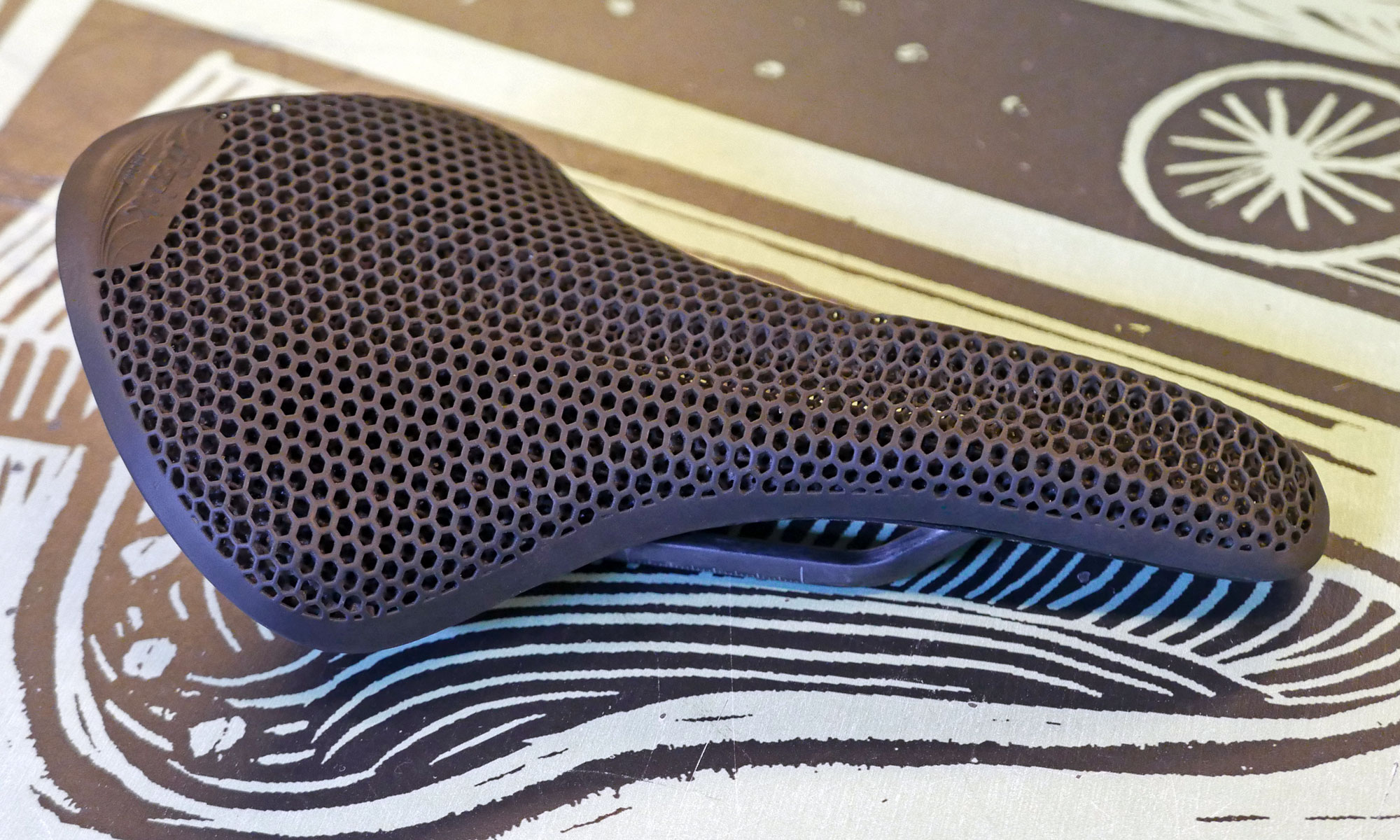

I went to Italy a little over two months ago and got my own custom fit, 3D-printed Fizik One-to-One Adaptive saddle. The process put me on a wide 155mm Aliante saddle shape, which I would not have thought of. And it identified an imbalance that me saw putting more pressure on the right side.

And the saddle it created is distinctly asymmetrical in its padding stiffness. There is even a super soft area on the middle of the left side where it feels like there is almost no support, but which corresponds to my pressure readings.

The Fizik One-to-One Adaptive saddle does not correct any fit issue or correct imbalance that you currently have, it simply responds to the pressure from your sitting positions, and accommodates that with matching support.

So, I have been riding most of my road and gravel rides for the past several weeks on this saddle and I can say the fit is great. I don’t feel like I have the flexibility to move around as much on the saddle as I normally would on a flatter saddle. But I am perfectly content to just sit in place and spin, in total comfort.

I know it’s not cheap. And I know for cyclists with multiple bikes, the thought of spending five hundred bucks on every saddle is a bit wild. But we spend so much time sitting on a saddle. I think it is really worth putting in the extra effort to optimize comfort under your butt.

Fizik One-to-One Adaptive saddle – Pricing, options & availability

The new Fizik One-to-One 3D-printed Adaptive saddles are available now when you get a custom fit in one of their select 25 worldwide dealers already equipped with the special trainer and pressure-mapping tech. Get fit, and get a custom saddle.

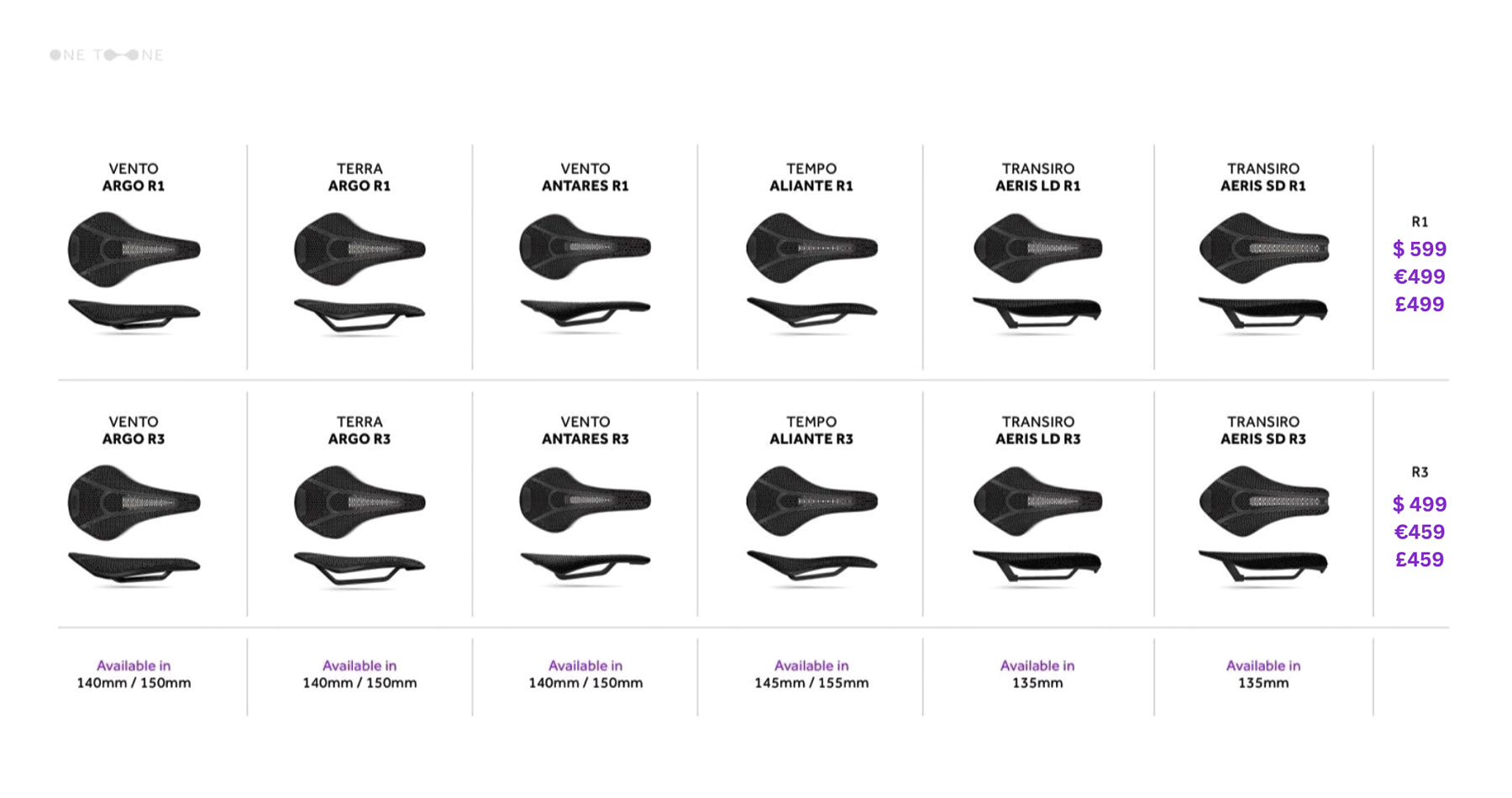

The saddles themselves are available in six shapes on carbon-reinforced shells, and 2 widths each, from road to gravel to XC to triathlon.

And pricing is $499 / 459€ for the R3 series with ti Kium rails, or $599 / 499€ for R1 with full carbon rails to save a few grams. Fizik chose not to offer a custom One-to-One Adaptive saddle at the full carbon 00 level, as the additional stiffness does not ensure the same rider comfort afforded by the custom fitting.

All saddles are made-to-order (obviously) in the northern Italy factory headquarters of Fizik. And once ordered and paid for through your local shop, Fizik will either ship it directly to you. Or you can have it sent to the Fizik dealer shop where they will do a follow-up pressure mapping test to show how your saddle pressure has improved.

You’ll be riding on a custom 3D-printed saddle about 2 weeks after you get your custom fit.