Thus far, we’ve all had to rely on some sort of lubrication in our bearings to keep the balls spinning freely. Why? It’s not because of the inner and outer surfaces. It’s all because we’ve relied on cages in between them to keep each ball bearing separated from its neighbor.

That prevents the balls from rotating against each other and slowing things down, but it also adds friction.

Now, Japanese company Coo Space has developed an entirely new inside surface that separates the balls without the need for a cage. And without any grease, lube or oil.

Check it out in the video below that’ll leave your head spinning…and spinning…and spinning…

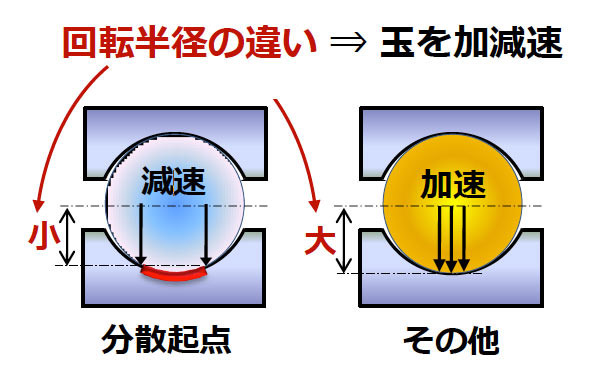

Essentially, there are small recesses in the outer ring that let the balls speed up to stay ahead of the ball behind it. By placing them just so, they maintain a constant speeding and slowing of each ball and keeping them spaced apart. It’s called Autonomous Decentralized Bearing, and here’s how it appears to work:

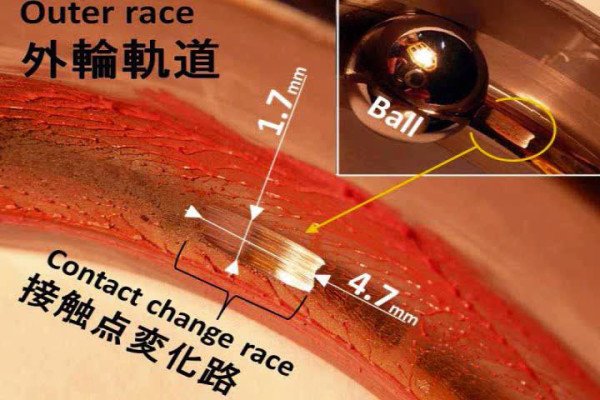

As the ball rolls over the divot, the contact patch (and radius) on which it’s rolling changes.

The divot (left) changes the contact patch of the ball from a single spot at it’s outermost point to two spots at a smaller radius, allowing it to spin faster. This speeds it up and lets it jump ahead of the ball behind it, keeping them separated.

The divot (left) changes the contact patch of the ball from a single spot at it’s outermost point to two spots at a smaller radius, allowing it to spin faster. This speeds it up and lets it jump ahead of the ball behind it, keeping them separated.

They’re looking for licensees, so here’s hoping someone jumps on this for bottom bracket and wheel bearings ASAP.

Via PopularMechanics by way of BikeBiz, with our own technical research added.