Just last week we found Empire Cycles’ 3D printed titanium mountain bike frame, and we’ve seen plenty of 3D printed parts and prototypes over the years from plastic and metal. Now, carbon fiber is on the menu.

The MarkForged Mark One was created to rapidly produce prototypes that could be tested in high stress, real world conditions. Think race cars, and making prototypes that can be taken to the track.

By printing with continuous carbon strands laid into thermoplastics, the result claims to be 20x stiffer and 5x stronger than nylon parts with a higher strength-to-weight ratio than CNC’d 6061-T6 aluminum. We’re thinking that could mean trail-ready rocker arms and suspension bits that could withstand a few runs to see how linkage changes affect performance in real life.

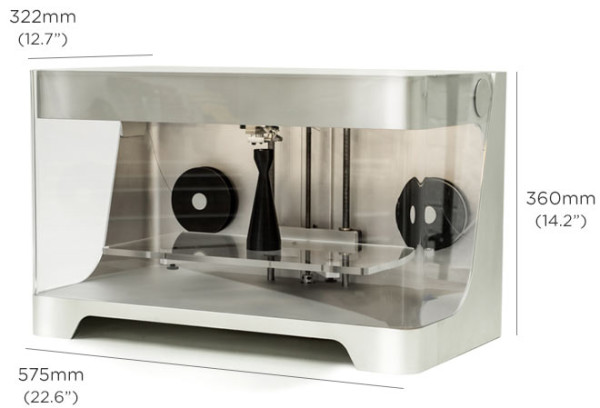

The machine uses two print heads, so it can also print Fiberglass, Nylon and PLA (thermoplastic). From the looks of it, it needs to embed the carbon into another material (check founder Mark’s speech at SolidWorks World 2014, jump to 35 minutes in, video after break), which would mean it’s not quite ready to pump out production parts, but the prototyping possibilities alone justify the $4,999 price.

Preorders are being taken now, delivery expected late 2014. Get yours at MarkForged.com.

The carbon fiber strands are printed near the outside of the structure to maximize strength and stiffness, using the heat from the printed thermoplastics to cure the part as it’s printed. We’ve reached out for more info on the process and if full carbon parts can be created, updates as we get them.