Exodux, a company better known for their bike racks for use with trucks, have turned their product design attention beyond the matter of bicycle shuttling, and towards the bicycle itself. Their latest product is the simple tubeless valve stem, but this time, they come with a twist. Exodus’s Tubeless Valve Stems feature a simple but, as far as we know, new mechanism for cinching down the locking ring with sufficient torque to prevent slow leaks.

Exodus Tubeless Valve Stems

The Exodus Tubeless Valve Stems themselves are composed of a machined aluminum stem with a removable core, just like the plethora tubeless valve stems you’ll see on the market. They are “high-flow”, meaning their internal diameter is sufficient to allow rapid entry of air into the tyre to seat it, tubeless. At 40mm long, they should also be sufficient for most mountain bike wheel rim depths.

What’s different about the Exodux Tubeless Valve Stems is the mechanism by which the lockring is cinched down onto the rim outer. To prevent a slow and utterly infuriating leakage of air from the valve stem, it is essential that the torque on the lockring is sufficient to pull enough of the valve stem through the rim to create a tight seal that is 100% flush to the inside of the rim. Often, it is difficult to achieve such torque by hand, especially if the lockring is of a poor design and doesn’t offer enough purchase to grip. Some brands have attempted to make the process of tightening the lockring by hand easier with oversized and irregularly shaped lockrings; Peaty’s, for example.

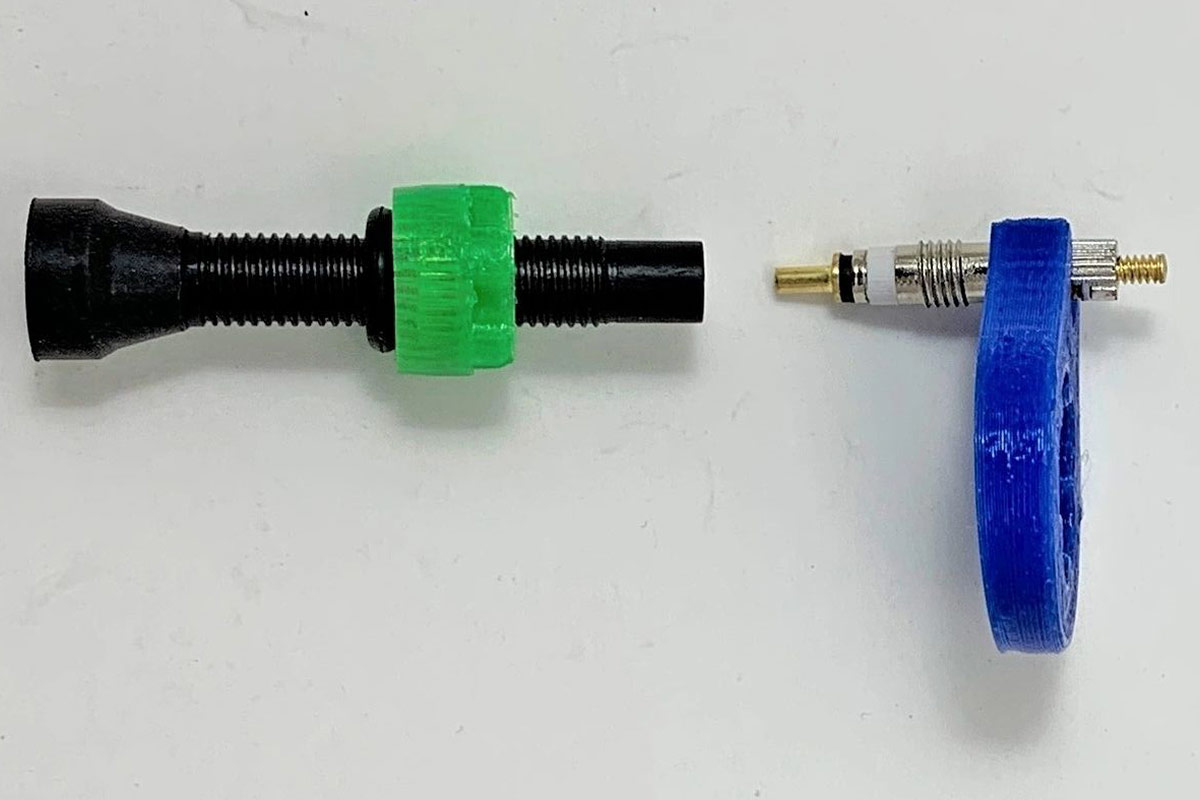

Exodux have gone a step further, 3D printing a lockring with a brass threaded insert, complimentary in shape to a small tool, also 3D printed, used to tighten the lockring. The pentagonal lockring driver also features a valve core tightening tool portion. The tool should make tightening the lockring a heck of a lot easier than having to fumble about with a tiny piece of, often, circular metal with insufficient purchase.

In theory, the design of the Exodux Tubeless Valve Stems seems sound, but I can’t help but wonder whether the material lockring material and tool are of sufficient strength to tolerate the torque that they’ll be subjected to.

Put the Exodux Tubeless Valve Stems to the test for $23.99 per set. Each set comes with two tubeless valve stems and one tool. You can order an additional tool for $3.99, when you lose the original. The valve stems are available in anodized black only, but you can choose from red, black, blue, translucent lime and hot pink colors for the lockring and driver tool.