If you’ve not heard of I Chu Technologies, it’s probably because they’ve been behind the scenes winding coils for Fox, Rockshox and others’ rear shocks. Lately, they’ve been developing new XLS Springs, which promise insanely long life and titanium-like weights, all for the price of a steel spring.

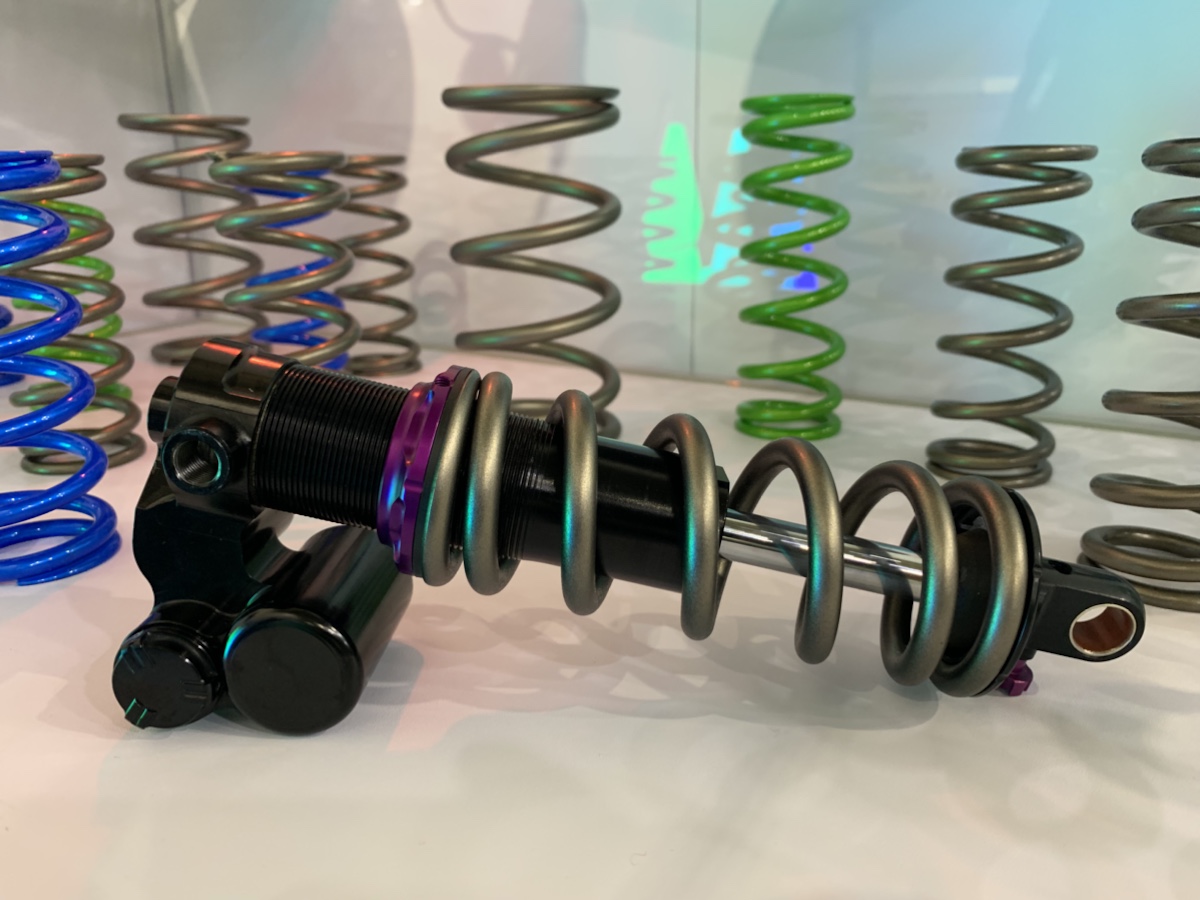

Well, the price of a premium steel spring, but still about 1/10 the cost of a titanium spring upgrade. Their new XLS coils qualifies as SAE 9254 steel, but I Chu uses different trace elements in there to create a high tensile strength steel that’s as light as titanium. Because the steel is so much stronger, they can not only make the wire diameter thinner, but they can spread the pitch a lot further, reducing the total number of coils by roughly 25%. All told, it adds up to massive weight savings.

They make the traditional springs for Fox, Rockshox, Ohlins and others, but DVO has already jumped on board to offer the new one as an upgrade option. And they’re in talks with Fox and Rockshox.

They’ll be selling them aftermarket, too, with distribution already in Europe, and the US market is coming soon. As for the name, technically, it’s “I Chu” as the words, but most people write it as “Ichu” in case you’re searching around the Interwebz for them.