Alto Cycling has updated their road and mountain bike offerings, coming fully modern with a hookless design for both, Boost hubs and XD options on MTB, and more colors for anodized hub shells and rim decals. We covered those last two cosmetic options before, but the road tubeless rims and mountain bike wheelsets are all new. Video above provides the run through, then read on for a little more techy chat about why they went hookless.

“It essentially came down to the profile of the tire bed and making that channel so that the air pressure wouldn’t be able to lift the tire over the sidewall,” says CEO Bobby Sweeting. “So it’s the height of the sidewall and the depth of that channel that the bead locks into so the pressure is pushing the tire outward against the sidewall and not upward over the sidewall.”

They test it up to 170psi in terms of yield strength testing so they know the composites will hold up, but limit real world use to 110psi to ensure the tire will stay on. They also tested as low as 20psi, trying to pull the tires off sideways…which means these are rated for cyclocross, too. Their recommended minimum psi depends on tire size, but for 28-40mm wide tires, they say running them down to 25psi should be no problem.

The new CCX52 is about 200g lighter per wheelset than the 2017 CCX56, and the disc-brake specific rim itself is 100g lighter than the rim-brake version of that same model. Sweeting says weight savings come from updated construction methods – ply orientation, number of plies, absence of a hook, and lack of high-temp resin and brake track materials. The sidewall itself is two plies thinner (look for more on that with future rim brake products, too…hint, hint). They also removed four plies from the spoke bed by replacing it with a small 3K woven section at each spoke hole rather than building up material around the entire rim.

He says, in general, once you take away the rim brake heat and pressure (from the pads, pushing inward) issues, you could theoretically get away with less expensive resins and manufacturing processes because there were several major stressors on the rim that no longer needed to be addressed. So, to improve margins or compete on price, cheaper rims may not made with the same proven methods and materials. So, Alto Cycling kept using steel molds and EPS mandrels, both of which cost more than alloy molds and bladder molding, but result in less deformation and more uniform heat transfer. He adds that most quality rims are using steel molds, so this isn’t unique to them, just trivia worth mentioning.

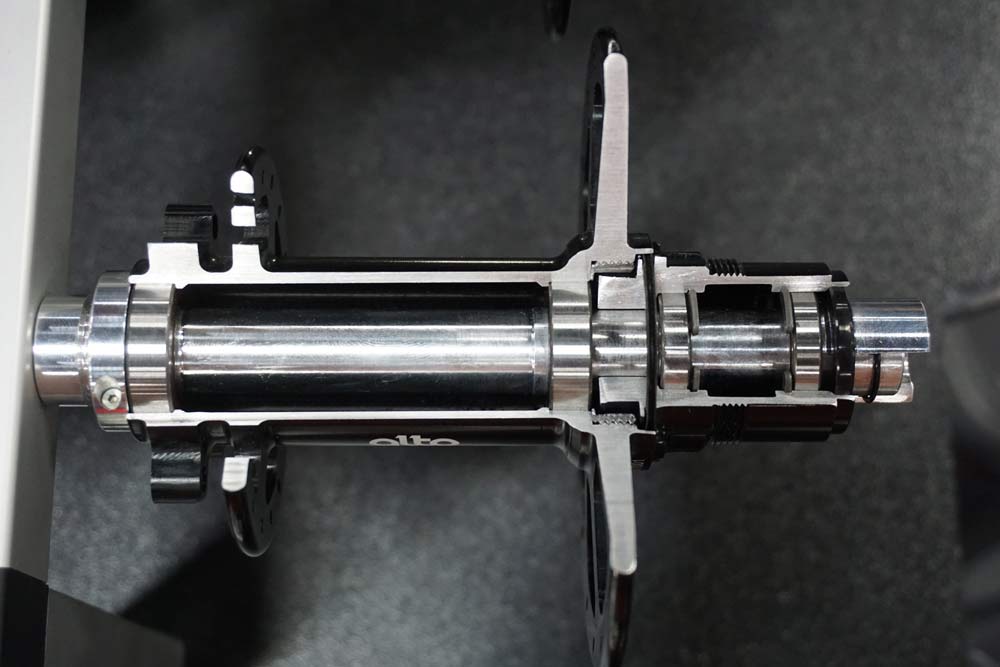

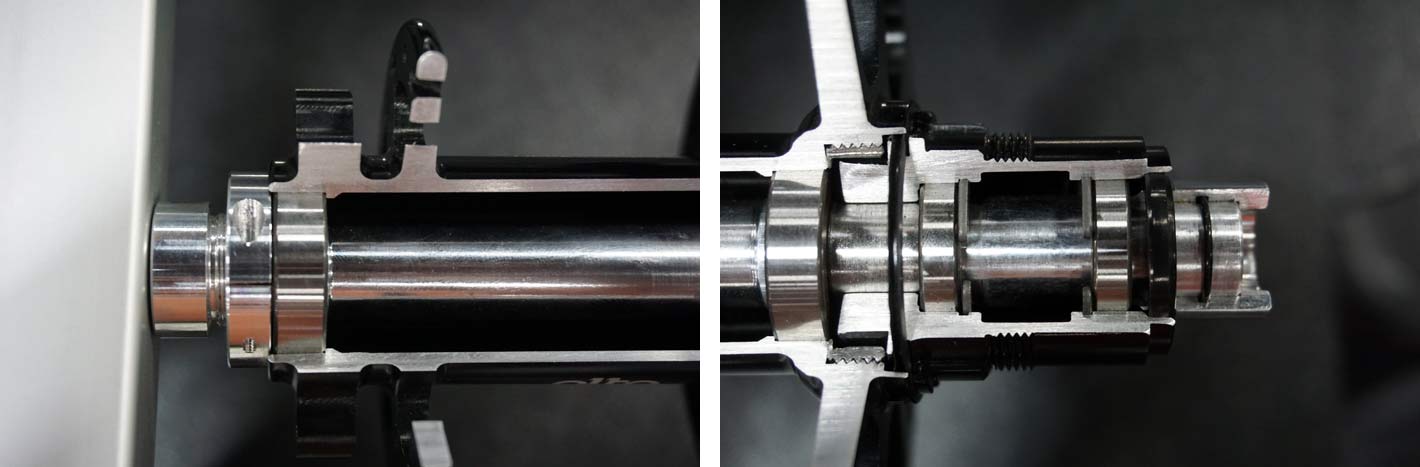

They went with 6-bolt rotor mounts because they could get the bearings a full centimeter wider, putting it directly under the rotor mount. With Center Lock, they had to run the bearing under the flange, much further inboard, which reduced stiffness by 12%. For folks really wanting the Shimano IceTech 40mm rotors, they recommend checking out the SwissStop rotors, which they’ve tested and shown to run cooler (their words). Scroll down for a complete spec and weight sheet.

2018 MOUNTAIN BIKE RIMS & WHEELS

For their mountain bike wheels, they’ve added wider rims to accommodate Plus-sized tires.

The bigger news is they now offer true Boost hubs with no adapters or spacers, and you can order their wheels with a SRAM XD Driver Body.

The hubs get an updated assembly method that puts the lock ring on the non-drive side, which threads tight until touching the bearing, then is locked down with an allen bolt. The design prevents any play without side-loading the bearings, so everything runs smooth and solid.

2018 ALTO CYCLING DISC BRAKE WHEEL SPECS