In an increasingly competitive market, usually we hear about companies that only used to make products in the USA. That’s why it’s quite surprising to see that Ibis has a new addition to their line up – and the front triangle is made in the USA.

Carbon 831 Lab

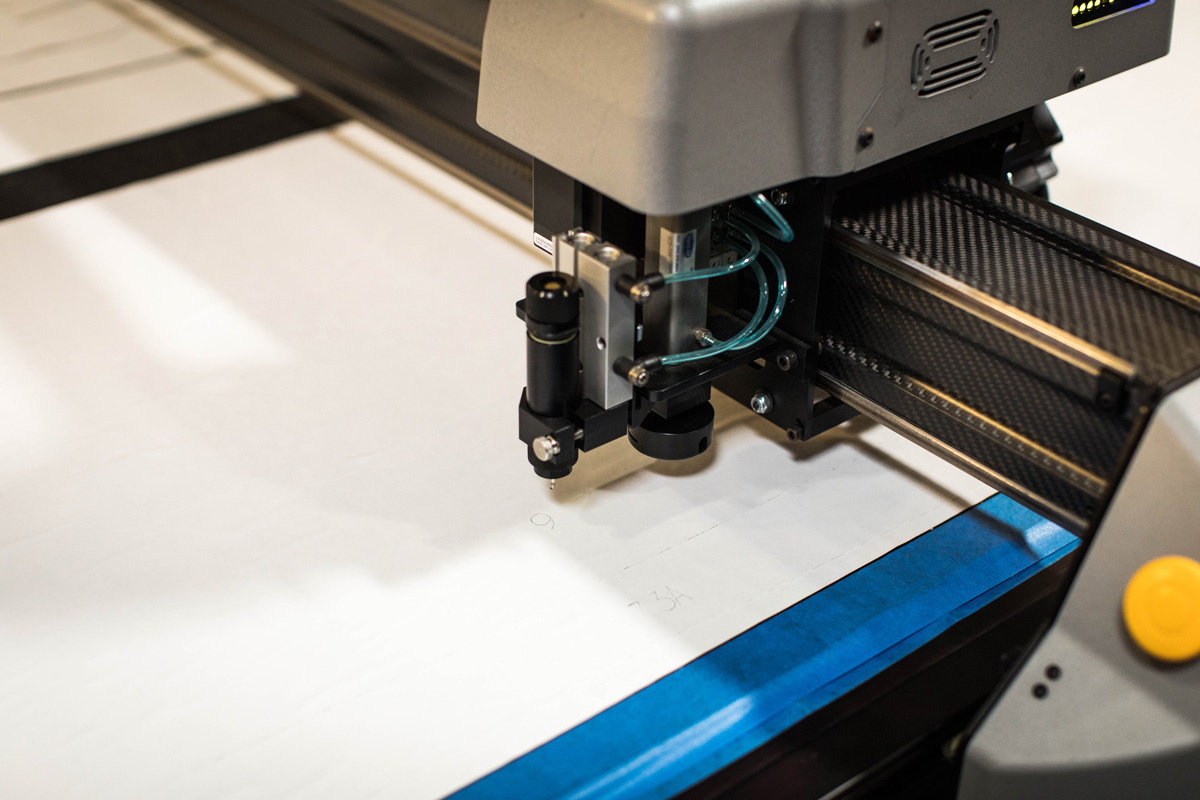

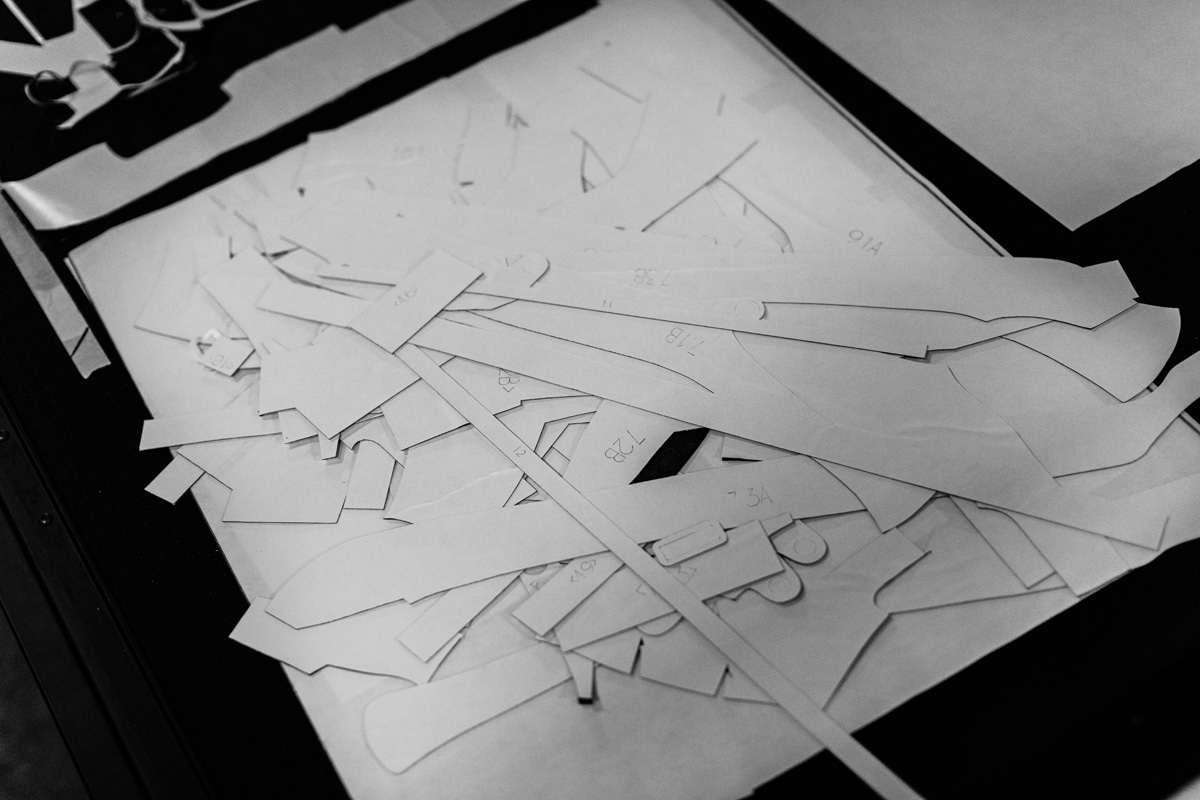

As the story goes, about four years ago, Ibis started their own carbon fiber lab in their Santa Cruz headquarters. The goal was initially to allow them to experiment with prototyping and product development. They didn’t create Carbon 831 with the goal of in house manufacturing, but the development process led them to consider what was possible. In order to make the operation feasible, the frames would have to be made using cutting edge techniques and processes to eliminate as much of the finishing time as possible. Ibis contends that it’s the sheer man hours needed to build and finish carbon frames that makes U.S. production so much more expensive. More expensive employees = more expensive bikes. But if you were able to cut down the amount of time that goes into each bike for things like sanding, putty, primer, etc, you might be able to make it work.

Through the use of improved frame layup and build procedure, that’s exactly what they’ve done. According to Ibis, their U.S. made front triangles use only around 100 pieces of machine cut carbon pieces, while the Asian made frames use over 350. The smaller scale allows for more precision and the result is a California-made frame that is 150g lighter and takes about 40% less time to produce. To get the full picture on Carbon 831, check out the Ibis post here.

Ripley LS Size Small

So what is the first product to emerge from Carbon 831? That would be the new Ripley LS in a size small. For unfamiliar, above is a photo of Ibis designer and co-owner Roxy Lo. Roxy has designed every Ibis since 2005. Standing tall at 5’1″ though, Roxy needs a small bike – something Ibis didn’t offer when it came time for the new Ripley LS. The bike was introduced at a time where shorter riders were still unsure of the bigger wheels, and after poor sales of the size small Ripley, Ibis decided they couldn’t risk sitting on a bunch of small Ripley LS frames that didn’t sell. However as usually happens, the customer has spoken and enough people have asked for a small Ripley LS that they wanted to make it happen.

One thing Roxy has always made sure of on her designs is that the small bikes get the same great performance as the larger bikes. This time though, it looks like the smallest Ripley LS will get the highest performance thanks to the lighter U.S. made frame! It should be noted however, that only the front triangle is made in the USA. The rear swingarm is still produced in Asia.

The small Ripley LS includes all the features of the bigger bikes like 120mm of rear travel, water bottle mounts inside the front triangle, great standover with plenty of room for a dropper post, and modern geometry. The frame features a longer reach, 75° seat tube angle, 67.5° head tube angle, and clearance for 29 x 2.6″ tires.

To keep all that U.S. made carbon visible, the front triangles are left raw with a protective Cerakote over the decals.

Maybe most impressive is the fact that Ibis is offering the small sizes for the same price as any other size in their range. That means you’re getting a lighter, made in the U.S. front triangle for the same amount of money. Like the M-XL sizes, the Small Ripley LS starts at $2833 for the frame only with a Fox Float Performance shock, or $2999 for the frame with a Fox Float Factory shock, and complete builds starting at $4,099 with a SRAM NX Eagle build up to $9,399 for a complete SRAM XX1 Eagle build. All Ripley LS bikes including the new small size are available now.