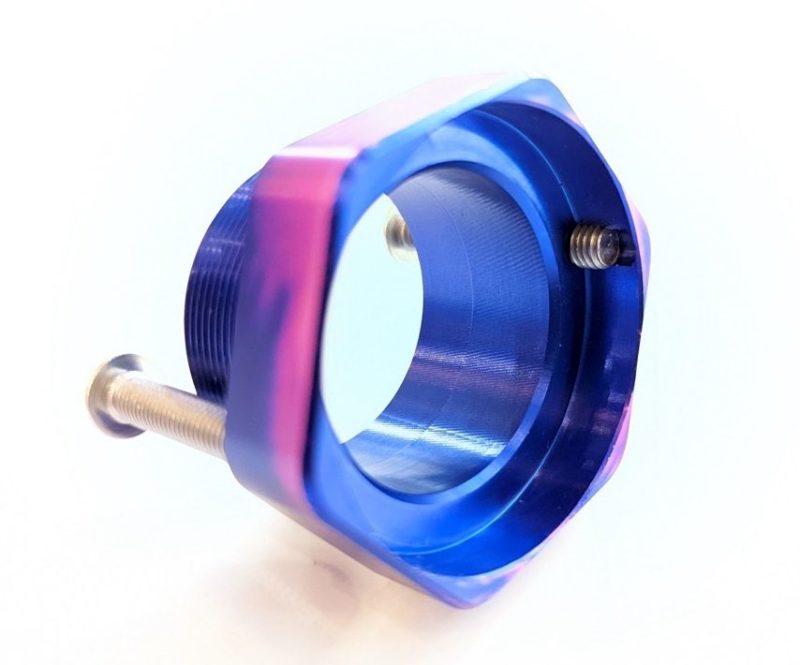

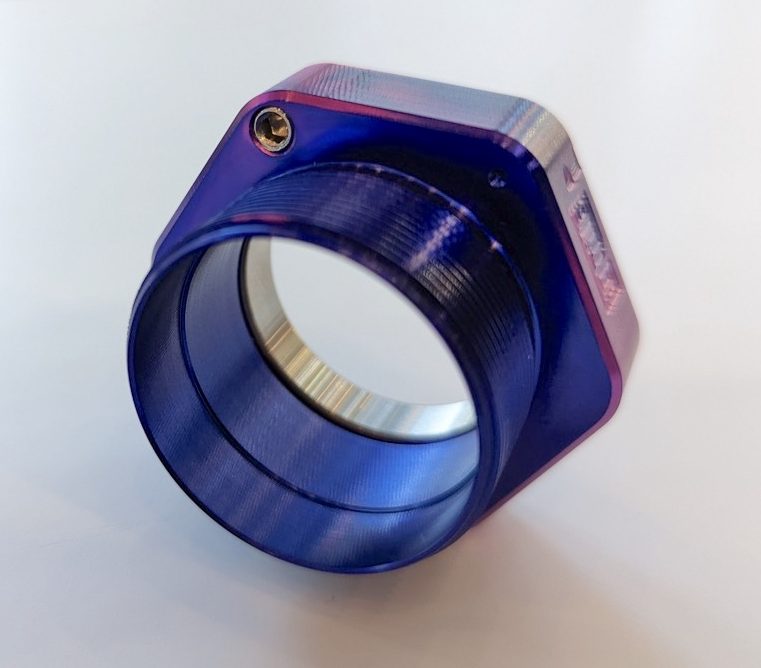

While at the Philly Bike Expo, Ignite Components had an early sample (not quite a prototype) of their new Bottom Bracket. We’ve covered Ignite’s wild cranks in the past, and this new bottom bracket design seems to be the same caliber of quality. But this isn’t just a bottom bracket. It’s a bottom bracket with a bearing extractor tool built right in.

The bottom bracket will come with two M4 screws that you can use to service the bearings. Once the bottom bracket is removed from the frame, you remove the small set-style screws.

After the small set-style screws are removed, you inset the longer m4 screws to start turning them and pushing the bearing out. I didn’t sample it, as these were not quite production-level samples, but it looks easy enough.

While they probably aren’t used as much as they should be, Enduro Bearings offers tools to remove and install bottom bracket bearings rather than throwing away the whole thing and starting over when the bearing wears out. This accomplishes the same thing, but in one complete package.

Another feature of the Ignite Bottom Bracket is the outer hex shape of the cup. No special installation tool is needed. If you wanted to, you could use a big adjustable wrench or, an old threaded 44mm headset wrench. But, Ignite says if you don’t have either of those wrenches, the bottom bracket kit will come with a proprietary tool that will allow you to install the bearings into the cups using a good ol’ hammer that won’t damage the cups or the bearings. And, this same tool can also be used to install the loaded cups into the frame’s bottom bracket shell by encompassing the whole bottom bracket (including the hex), allowing you to use a 3/8″ socket wrench to thread it into the BB shell and torque it down.

They didn’t give me an expected time of availability or retail price as of this post. But stay tuned as I’m sure we’ll know when it comes about.

Check out their kick-ass crank offerings at the link below.