Like most great bicycle tools, the first repair stand was born our of necessity. The first prototype for the first production bike stand was welded together in the back of a hardware store in St. Paul, Minnesota. Fabricated to place the drivetrain of the bike at a comfortable working height, the stand was a huge improvement over working on a bike upside down on the floor. Five decades later, the descendants of this stand and the specialty tools developed in parallel are so pervasive within American cycling culture that it is almost inconceivable to see a shop or race pit without them.

The story of Park Tool is the story of establishing and supporting the American bicycle dealership as a professionally independent entity. Now in its fifth location (if you include the original hardware store), Park Tool produces 3500 individual parts for over 400 individual tools to support component and bike companies as well as bike shops and, more recently, consumers. Owner Eric Hawkins, son of co-founder Howard Hawkins, sat down with me to discuss the origins and current educational emphasis of the friendly blue tool giant of the industry…

BIKERUMOR: There was a point when there weren’t bike specific tools. There is a very standard set-up for what a bike shop is now- a standard set-up of tools and equipment. The interesting thing is that it didn’t exist, and that Park Tool is a big part of why bike shops look the way they do.

ERIC: There is a timing thing too because back in the really early days, there wasn’t much of a need for specialty tools. There weren’t gears, there weren’t hand brakes. There were thin wrenches and hardware store tools. So almost about the same time that we started making more specialty tools was when there started to be a derailleur on a bike and hand brakes and so on, so not exact the same time, but they still worked on bikes upside down on the ground. Now, there were some stands but they didn’t rotate, they basically just kinda clamped the bike in there.

But a lot of the really early pictures from my Dad’s bike shop, the bike was upside down on the ground. So that’s the way they worked on them. It kind of was this evolution that happened along with the bicycle that we at Park Tools started to make specialty tools and as the bikes changes, we changed along with them. And now there are 400 tools, 15 different repair stands, and countless directions to go. So there are some different types of shops for the most part, yeah, there’s a standard set-up that you are expected to have as a professional bike shop.

BIKERUMOR: And it’s so standard that people don’t even think about it. The early tools for Park, before it was Park, the tools that were being developed by your father and his business partner, Art… what got them started? What were the early tools that they were producing for themselves?

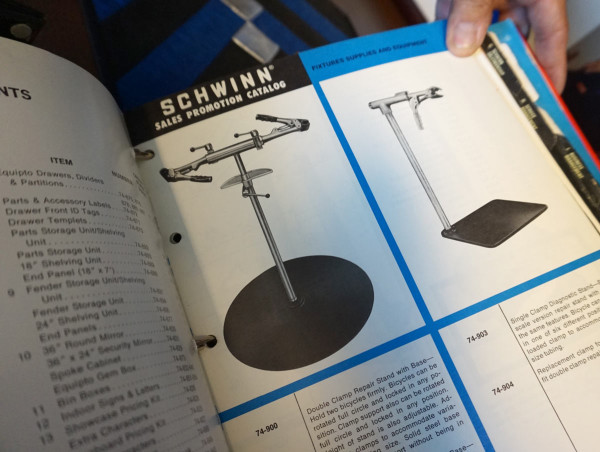

ERIC: They made a stand and then the story involves Schwinn because in the early days, do you know Jay Townley? Jay Townley worked for my dad as a teenager, as a 13 year old and all through high school. And then he got his first job with Schwinn. And he knew that my dad and his partner had worked on some tools for themselves. The stand was the main thing. To get the bike up in the air and turned. But Jay was put in charge of professionalizing the bike dealer and part of that was the tools.

BIKERUMOR: Why was that an emphasis for Schwinn?

ERIC: Because they were trying to get out of the hardware store or lawn mower shop dealers. They wanted it to be more progressive.

BIKERUMOR: There were Schwinn shops that were like “Schwinn da da da and Mower.”

ERIC: Part hardware store- part whatever they could do. And bikes were just a part of that. In fact, my dad’s original shop it was called Hazel Park Radio and Bicycle because they tested radio tubes. They fixed lawn mowers. They sold ice skates. They sharpened blades for lawn mowers. Anything you wanted fixed. Bikes were just a part of that. So Schwinn was trying to professionalize the bike shop to be-

BIKERUMOR: A bike shop. Like a car dealer.

ERIC: It was kind of the early days of the concept store. So Jay, that was one of his jobs was to professionalize the bike shop. Schwinn actually put up some money in the beginning to pay for some tooling and all the tools in the beginning were Schwinn branded. And then Schwinn had the whole disruption in their distribution.

BIKERUMOR: What was that “disruption?”

ERIC: It was in the early 70’s, I believe, and Schwinn was using independent distributors and Schwinn decided to sell through their own distributors. They had Schwinn West, Midwest, South and East. So they basically fired all their independent distributors. In all there were 15 or 20. So they all got fired, basically, and they are the ones that sued. So at that time, the other distributors went out and created the Vista brand- that was made by Columbia. They were trying to replace the Schwinn brand with their own brand and named it Vista. It was at that point that we were making tools red for Schwinn. And the old distributors still wanted to buy tools but can’t sell the Schwinn tools.

BIKERUMOR: And they didn’t want to at that point.

ERIC: Yeah, they didn’t want to. So that’s when we switched over to the color blue and that’s what we’ve done ever since.

BIKERUMOR: Wow, I didn’t know that.

ERIC: We don’t talk about that because it’s not that important. But we continued to sell to Schwinn under their name and under our name, under Park Tool. But the first stands said “Hazel Park Cycle Center Repair Stand.”

So this is the original stand.

BIKERUMOR: Oh wow! Is that base from an office chair?

ERIC: No, that is from a kitchen table. We have pictures of them using pictures of that stand from the mid 60s. Of course, they didn’t take a lot of pictures. So this was a hub from an industrial bicycle. So this was a hockey stick for the handle. This was a truck axle. This is a printing roller or something. Kitchen table legs.

BIKERUMOR: This is amazing!

ERIC: It just kind of rattled around on our shelves for years. Then one day, I think it was our fortieth anniversary, we brought it to Interbike on the back our pickup truck.

BIKERUMOR: And people lost their minds

ERIC: And that one over there is the first production model.

BIKERUMOR: So when bikes were initially put on these, what kind of orientation were they in? So this spins?

ERIC: In the beginning they would clamp it on the seat tube. My dad always worked on them upside down. You’d put it in there and turn it upside down.

BIKERUMOR: This is blowing my mind right now. I’ve always been very interested in technology within the industry that became completely pervasive overnight. This is an example of a bike shop-centric technology like that. There were some bike stands, but not really a standard. And then suddenly there was this bike stand everywhere. So this is the first production model. When was this?

ERIC: Mid 60’s. This is what the original stand looks like.

BIKERUMOR: So how does this extend up?

ERIC: It doesn’t.

BIKERUMOR: So when did it start extending?

ERIC: When people started hanging bikes by the seatpost. The model after this has a flat plate, it probably went up 48 in.

BIKERUMOR: So your dad always worked on stuff upside down. The model of this is higher to represent the change in how bikes were worked on. Interesting stuff. So where did that change come from?

ERIC: I think people just didn’t work on them upside down anymore. Now we’ve got some that are seven feet high and are electrically powered. The whole idea of a work stand is to put the work at a comfortable level. Just like in an auto dealership.

BIKERUMOR: It’s an ergonomic device.

ERIC: You don’t work on the brake on the ground. It puts it right in front of you.

BIKERUMOR: Mechanics get thrown so few bones, it’s so cool to have this organization that was founded by mechanics who wanted to create an ergonomic working experience for mechanics.

ERIC: And solve a lot of problems. They were just trying to make a living and trying to solve problems. You look at a bike shop and it’s all about being efficient. Being faster and doing a better quality of work.

BIKERUMOR: So these are iterations on the stand clamps?

ERIC: Well, this one here is the second version of that original one. This is what the production one is based off of. This was still a prototype. They got a patent on that. That clamp became that clamp. That was the first patent.

BIKERUMOR: What was the patent exactly?

ERIC: The over center clamp. This one is adjustable here. And pipe threaded at the post. And this is a 3D printed model of our modern clamp.

BIKERUMOR: It’s so cool to have all this history in one room! Again, people don’t know why things they are the way they are. It’s interesting- you have the people that make parts and people who make tools for those parts. Those entities are so critical to one another and to the industry, to the consumer.

New standards come out all the time, you can’t just be reactionary. The industry needs tool companies to be enrolled for it to be successful, for new product to be seamless. How do new tools get developed?

ERIC: That gets worked out a bunch of different ways. Sometimes we wait for a new standard to actually be something so that we’re not tooling up for something that fades away. There are a bunch of different things going back. Shifting systems, bottom bracket systems. Sometimes manufacturers want the validation from us- to come out with a tool, sometimes it validates what they are doing. If Shimano comes to us saying that they are using this new bottom bracket in the next two series down, we’re all in. Sometimes something new comes down and they want the coverage and they want the validation, and they don’t want to be that guy that puts out a part and there are no tools for it.

So Campagnolo comes out with a new 11-Speed chain and the question at the tradeshow isn’t if we’re going to make [the new tool], but when it will we have it. There are other tool companies out there but they don’t always have the answer because they aren’t automatically going to make it. So we average between 15 and 30 new tools every year. A lot of them are just solving problems. Some of them we’re rebooting something or we come out with a new stand or a new way of doing something or an addition to a line we already have. But a lot of them are for… hydraulic brakes, now you need more stuff. Disc brakes, gotta have more stuff. Now there are three different ways that you mount them- need more stuff. And we are the ones that keep up with all of that.

BIKERUMOR: And how spoiled are we as a community that that just happens and we never have to think about it?

ERIC: Magic.

BIKERUMOR: It is magic!

ERIC: We do our part, and you do your part and buy it when it comes out. We’re happy with that arrangement.

Our advantage is that we’re a nice size where we can react. We can put resources behind making that stuff happen. We don’t have to say “boy, we should really make that but we can’t that year. We’ll get it next year.” It’s all we think about. It’s part of another line. I mean, we have pumps and this and that and lubricants but the fact is that we’re a tool company and we’re here to make tools. And the industry gives us new tools every year. We don’t have to ask for them. They make changes; guess who are the good guys? We’re the good guys because we’re going to give you a solution.

I would describe us a Switzerland. SRAM comes to us. Shimano comes to us. Race Face comes to us. If we were part of Shimano, SRAM wouldn’t send parts to us. We’re in a really good spot. But we can’t just sit back and be comfortable with it. We have to keep going.

BIKERUMOR: I don’t think that people appreciate how pervasive you are. You’re not just Switzerland. If Park Tool disappeared tomorrow, there would be such a void-

ERIC: For a little while.

BIKERUMOR: I mean it, if tomorrow, every Park Tool product ever made suddenly vaporized- every system, stand, book, article suddenly disappeared, there would be such a huge void. You’re such a massive presence, but in such a passive way.

ERIC: An interesting story that would tie into that. The same thing goes for almost every start-up business. They say that “if this would have happened, this wouldn’t have happened,” right? My dad was telling me that in that early bike shop, my dad and his partner were both of the service. My dad went to welding school and he was selling welding supplies out of a truck. That was his first job. And his partner Art was working on the railroad. Neither of them had any money. My dad borrowed some from his brother in law. Art borrowed his share from his parents. They bought this existing fix it shop where these two old guys were going to retire. The first year they sold 56 bikes. Their best year they sold almost 8000 bikes.

BIKERUMOR: So that’s a lot of growth.

ERIC: Yeah, in about 20 years. Anyway, the story is that they sold ice skates and they sharpened lawn mower blades- they didn’t have any money but they had to buy inventory. Now, in Minnesota, ice skating was at that time all outdoors. So they had inventory for Christmas. And they said that their first year that they needed to get their inventory in there but they didn’t have money to pay for it. If it didn’t freeze before Christmas, they would have been stuck with that inventory.

That year was an early freeze. It flooded the rinks. And they got to continue business. He said they would have been out of business if had been a warm December. So those stories are cool when you think back. If they went out of business, there would be no business. There would be no Park Tool.

BIKERUMOR: Changing topics a little, why was important for Park Tool to take on Calvin Jones as its mascot?

ERIC: I was looking for someone to help us keep up with industry changes and trends and I had some education ideas that I wanted to do. So one of the first things he did was start writing articles because my belief is that because everyone trusts in one form or another, we can be the guardians of mechanical information. Right? We can produce all this information and we’re a trusted source. We’re not a magazine. We’re not a particular manufacturer. We’re in the middle. So we did a lot of that in the beginning and Calvin wrote the first Big Blue Book, our repair manual. Calvin spends a lot of time with education. His title is Director of Education.

BIKERUMOR: When was the first one written?

ERIC: 2005. Now we have three of those. Before that, back in the day at the bike shop when we would have a slow time in the winter, we would do repair clinics for consumers. And every shop has it in their head that they want to do these, but they don’t know how to do them and they don’t have the materials. So that’s when we wrote the Park Tool School. For a while it was separate of the Blue Book and now they go together, so it’s taught from the book. But we provide all the materials for a teacher to teach the class. So it runs through the repairs but it also tells them here are the tools you need, here is the space you need. Here is the idea for today. Here is the reason we’re teaching them this and here is how to teach it. So he was instrumental in making that happen because he wrote all the material for it.

BIKERUMOR: So the school is for teaching consumers? That’s very cool.

ERIC: And we have thousands of them out there now. If you go on our website you can see all the bike shops that do it.

BIKERUMOR: That’s really interesting because there are definitely shops that don’t take those steps. What is the philosophy behind mechanics teaching people to be their own mechanics?

ERIC: We used to fight this a little bit. Bike shops would say, why would I sell tools? I want to fix people’s bikes and I want to charge them for it. And that’s still the idea with bike shops, right? They have a repair department and they are there to fix bikes. But if you teach somebody how their bike operates and teach them a few basic things on how to get back on the road, you’re going to make a better enthusiast. If you’re scared of your bike, you won’t want to ride because you’re going to get a flat tire and you have no idea how to fix it, you aren’t going to ride your bike. You’re making a better and more educated rider. You can build on that too to say that a more educated person, somebody who is more educated in their bike and how it works becomes more interested- you know, I understand how my brakes work, but now I know how this set of brakes work. I know why this one is better. And they get to be a better consumer.

Knowledge is power because now they know how the bike works and what makes a better bike. So you’ve created a better consumer for the bike shop. The bike shop is still going to get the more complicated repairs. They are still going to get people who don’t want to do anything- here you go. But some people take the basic things- I want to clean my chain. I want to know how to fix a flat tire. I want to be able to adjust my saddle and my handlebars. I want to be able to adjust my brakes or know why it’s rubbing. I’m going to replace my brake cables or I’m going to put a new chain on it.

BIKERUMOR: I know these are products I can buy to make my bikes better. The bike shop sells those products. The bike shop sells the tools, you sell tools. Everybody’s happy.

ERIC: We give education away. It is somewhat self-serving because we want to help people get educated because we want to sell tools, but we’ll give away that knowledge all day long. So we do that on several levels. We have the Big Blue Book 3 now with Park Tool School. We have about 130 articles on our website on “how to fix a flat tire” or “why is my bottom bracket squeaking?” And now we have more and more videos every week. We’re all about letting people know how to use the product and in the end we’ll sell more tools.