David Woronets joined the industry in a way a lot of ex-elite racers have: he needed a winter job. But unlike a lot of those ex-racers, David found himself compelled by manufacturing and development of the physical product. After moving around the industry and after working for Elsworth for several years, David saw an opportunity for a job shop model of domestic manufacturing and jumped at it.

Five years after purchasing equipment from Elsworth, David and his team have established Zen as a viable alternative to overseas manufacturing. At NAHBS this year, Zen released their full line of house product, realizing a long desire of David’s to produce his own product…

BIKERUMOR: You’ve been in the industry as a racer, a plant manager, etc. How did you get from that scenario to wanting to do something like this?

DAVID: It’s really simple. As a racer, I couldn’t afford to live off of racing so I ended up working for my sponsors in the off season, whatever that was, whatever capacity they would give me. I felt myself gravitating towards the manufacturing side of it. Yeah, race in the summer and work in the factories in the winter.

BIKERUMOR: In any capacity in the factories?

DAVID: One of my original track sponsors was a carbon and Kevlar disc wheel manufacturing facility in Southern California, Advanced Racing Research, ARR Sports. They had me laying shit, wrapping seatposts, and actually did vacuum forming Kevlar and carbon wheels which are really cool until they explode on the track and the sound, it echos for miles. But yeah, they were taking a lot of technology from the Soviet team at the time. A lot of that really- like bolt your shoes onto your axles because that’s more efficient- stuff like that.

So anyway, that’s how I got into the manufacturing side. And it wasn’t until ‘99 that I started going full time into the manufacturing side. I was still halfway into doing some free-riding, and I was team manager for some of the teams I was riding for, and just transferred to over here. As far as manufacturing history, as far as the full time gig, I worked as Production Manager for Chumba for awhile when they were doing US manufacturing. When they took manufacturing overseas, I got a purchasing manufacturing job over at Felt. So I got to travel over to Taiwan and experience how really large factories get to do it. So it’s kind of cool because I’ve tried to bring some of that back here, the stuff that I felt was valuable.

And then in 2007 I was offered the operations manager job at Elsworth Manufacturing in Vancouver, Washington. Came up to Portland, ran that plant for awhile. We were getting fairly consistent inquiries into doing outside frame production. Their business model wasn’t set up to take on outside frame production. So I made Elsworth an offer to buy the equipment, kept them on as a customer of Zen, basically just swapped everything out, and it allowed us to become a job shop where we can produce for other people.

Moved it over the river from Vancouver, Washington to this building.

BIKERUMOR: Super close to downtown.

DAVID: I live fifty miles from here, so I could have easily chosen a cheaper location closer to the outskirts, but I wanted to find the best employees. Portland is full of bicycle enthusiasts and if they can ride to work or take the MAX, better yet.

BIKERUMOR: So this reminds of a Taiwanese office with all the frames.

DAVID: We actually just got this back together from NAHBS. I literally, before you were here, started throwing everything back together.

BIKERUMOR: So Aluminum and Steel, do you do Carbon? Do you have plans?

DAVID: No. It’s just a different business model. I might as well do a whole new facility to just do carbon. Composites and metal don’t play well together from a production standpoint.

BIKERUMOR: You fairly recently started working with steel.

DAVID: As Elsworth we were primarily aluminum. When I opened Zen, we were steel right away.

BIKERUMOR: When was that?

DAVID: 2011.

BIKERUMOR: That’s boss.

DAVID: Yeah, we’ve carved out a little niche for ourselves and it seems what we’re offering, marketable manufacturing, so we keep our facebook feed full of customer’s products that we’re manufacturing so they can have their customers go to our social media and say, this is where our bikes are being made.

BIKERUMOR: So customers don’t keep it a secret.

DAVID: About half of them do. It’s up to them.

BIKERUMOR: Do you have in house product? Is it just external customers?

DAVID: This is new. This was released at NAHBS- our own line was released at NAHBS.

BIKERUMOR: So why that direction? In what I’ve seen written, there was an emphasis on proprietary technology being safe here, and an emphasis of not using other potential competing shops in the United States because they have their own house brand, that there will always be that or other conflicts of interest, scheduling conflicts. Etc. Why move into your own brand?

DAVID: A couple reasons. Obviously I’m a bike geek, I’ve been doing it for a long time. I finally got the chance to design the frames that I wanted to versus just built for other people. And just as an example, if a customer came to us and said “can you build a bike just like the Lemond Washoe,” we would say no. We have to do something unique. Zen is in the same spot. We don’t want to do anything to compete with our customers, our job shop customers.

BIKERUMOR: What does that mean?

DAVID: So we don’t have any product that mirrors what our existing customer base is doing. In a sense, we’re a little handicapped in our line but it also makes us be more creative. Like the road bike was thru-axle disc from the start. Just little things we could do to make them unique.

BIKERUMOR: So as far as your brand family, what ties it all together? Because this is an awful lot to have at once. Especially out of nowhere. Especially in steel and aluminum. There’s a lot going on here.

DAVID: Yes, I know. I don’t want to sound cliche, but we want to have feature driven bikes that were built by riders for riders. As an example, our steel road bike is thru-axle disc Di2 compatible, PF30, tapered, 1700g frame. So you could take all your parts off of your Madone and throw it on there. We wanted to build in metal and make everything as modern and feature driven as possible. And that goes across the entire line. And all these bikes are out to magazines now being tested and they are being well received within their individual class. So what ties them all together is- if I look at them, I’m not trying to start a mountain bike company and come in and buy road bikes later. I want to make the best in class for every design. Which is really cool to be able to do that, to be able to geek out on each category.

BIKERUMOR: Can you speak to another model in particular?

DAVID: I could talk about the things that are unique to each bike in its category. The AR45 is the gravel bike. I know that’s, whatever, I want to strangle people that use that category, but it’s a 29×2 compatible bike, thru-axle disc front and rear compatible. We’re selling it as a QR but it’s got our inserts that are forward compatible to thru axle. It’s a full true temper tube kit.

BIKERUMOR: Do you do custom tubing and forming?

DAVID: All our OE stuff is custom whether or not our customer delivers us custom models. As far as custom shaping and forming we do in house.

BIKERUMOR: Hydro-forming in-house?

DAVID: No.

BIKERUMOR: I was about to be very excited.

DAVID: Again, hydro-forming is a different business model.

BIKERUMOR: You don’t do machining in house at this time? Custom dropouts?

DAVID: CNC machining is done at a local source that has been working on our bike parts for 15 years. So it’s nice. When you say left dropout they know what you are talking about. Other shops are like: what? Can you give me a drawing number?

BIKERUMOR: Do you want to walk through a process?

DAVID: We’ll walk through an aluminum process. As an example, we get round tubes, turned tube aluminum. We’ll send them out to get them annealed. We put them on The Hulk with our custom dies and fixtures. This is a formed tube. Cope and mitering are various different set ups on these mills. Grinding and blasting- we keep the dust in that room with the exit filtration system so that the dust never makes it over to the welding area. The sanding is on the opposite side from welding so it doesn’t contaminate the welds.

BIKERUMOR: Where’s your paint?

DAVID: We don’t paint. We’re just a fabrication shop. Tubes staged, they’re going to go into, a tack fixture, get tacked, welded. We get those tubes into baskets. We’ll rack them so that the water travels in the right direction in the tubes. We send them out to metallurgical, to get the Aerospace pollution anneal. Which means it’s an oven suspended in the air. When it gets up to melting point, it drops them into the water when they are soft. Align them. Put them in our green oven. We’ll get them to 2-6. And we’ll do all the machining on all the bores. From there we’ll prep them for finishing. We’ll send them out for different finishing, whether that’s anodizing or powder coating. Bring them back here and do the final clean up then ship them out to customers.

BIKERUMOR: So all finish work happens somewhere else.

DAVID: Yes. Again, different business model I wouldn’t want to put a paint shop near all the grinding.

BIKERUMOR: You don’t want to deal with the paint warranty issues.

DAVID: We still do. We contract for people. We get the worst of both worlds. But we have some great local finishers and they are doing great work for us.

BIKERUMOR: So aside from The Hulk, what’s the most interesting machine you’ve got in here?

DAVID: This is actually it.

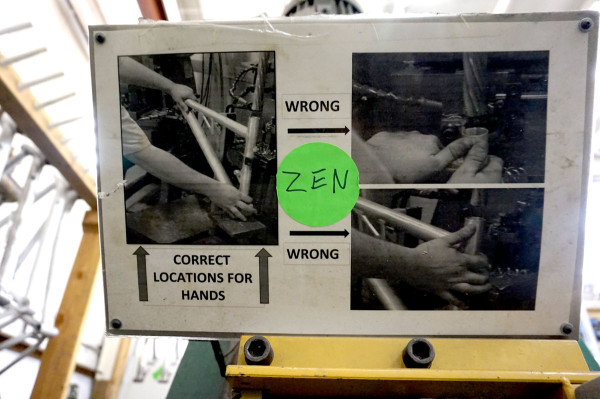

BIKERUMOR: This is a great diagram here. The engineers in the house will love it.

DAVID: And the crane. So when we moved in, we need these hot water tanks to clean tubes. This place used to be a paper mill roller facing factory. So what it would do is take these paper mill rolls that were 6ft high and on a machine that went from this machine that went from here to this wall. It was a surface plate that had a grinder that followed it and actually surfaced the roll as it rolled to accurate within a piece of paper. A six foot roll. In order to get that machine in and out, they had this 10 ton crank. We used to have our own little crane, but now we use this. Because why not, right? So we use our 10 ton crank to lower aluminum tubes in the water.

BIKERUMOR: That’s hilarious. That is a terrifying crane.

DAVID: This little tiny basket will have 10 aluminum tubes going down into the water. On this 10 ton crane. I can’t tell you… We should just put hooks on top of all the machinery and move it every day. We can move every machine in the range because it’s a 10 ton crane. We just use it for aluminum tubes into the hot water bath. It’s a monorail now because we installed all the electrical around it.

BIKERUMOR: Why the gym?

DAVID: You know in the wintertime when you get 2 hours of light a day…

BIKERUMOR: And when it’s hard to “get swole.”

DAVID: So we have a little spot where we can work out.

BIKERUMOR: How many OE customers do you have right now?

DAVID: That’s confidential.

BIKERUMOR: You clearly have at least one. Who is publically your customer?

DAVID: LeMond. VanDessel. Vassago. Turner.

BIKERUMOR: Do you do custom dropouts for customers when they ask for them?

DAVID: Absolutely.

BIKERUMOR: You’ve got customers that come at you with custom frame parts. You can fill in the blanks.

DAVID: Yeah.

At this point, Rick Zitzmann, the engineer for Zen, peeked into the room.

BIKERUMOR: Nice job, Rick. You’re crushing it on these dropouts.

RICK: Yeah?

BIKERUMOR: Well, I mean, they look good. It’s good stuff. With the little bosses? I’m into it.

RICK: Good. Plus, it allows us to align the dropouts rather than aligning to something that isn’t there. That’s the problem with bolt-on dropouts because you’re aligning to something that’s not there when you’re building it.

DAVID: You basically have a pocket that’s a mirror of where the dropouts are going to be. The CX frame is light, super stiff. Same dropouts so it can run thru axle if you want it to. Still very light. You can see the actual interface.

BIKERUMOR: Rick, what’s the coolest thing in the room? What are you most stoked on?

RICK: Just because that’s what I want to ride. Just around Portland. For commuting. Bike trails. Springwater corridor. Leif Erickson. Forest Park. It’s just a good Portland around town do everything bike. And it has fender mounts.

BIKERUMOR: Any particular feature that you’ve done on it?

RICK: No, the whole package. I mean, the dropouts are my favorite part.

BIKERUMOR: They are pretty, and pretty minimal. So these are the fender and rack mounts.

DAVID: We did inserts on the seat stay so we didn’t do weld-on fender mounts on the top to keep everything minimal so it doesn’t look like you’re riding a touring bike around.

BIKERUMOR: I like your yoke.

DAVID: Oh yeah. It helps to give us extra clearance. We try to keep it fairly close to cross geometry. It has a short rear compared to a lot of gravel bikes out there and accelerates it really fast. We wanted to keep the bottom bracket at Road-ish height with normal road clearance. The bigger the tires, the more cross clearance. The axle to crown is taller than a regular cross fork. What we did was the axle to crown is kind of like- set for a stock ENVE or Easton cross fork but if you used a tapered fork with the lower external cup, the Axle Crown comes out the same. So if someone wanted to put in an ENVE or Easton fork for an external cup, the geo’s the same.

BIKERUMOR: Yeah, that’s clever.

For more information on Zen’s house product or job shop production, visit their website.