In a compact studio workshop in North Portland, Jude Gerace of Sugar Wheelworks tailors wheels in the way that small builders tailor frames and bicycles. Working with each customer individually she sets out to build wheels to match the rider, context, and machine as a package. Jude backs up her consultations with extensive metallurgical testing and close collaborations with local engineers as well as a sophisticated wheel “taste testing” program so that customers can be confident in every aspect of the decision and purchasing process.

Jude talks about her process, advocacy, and bike touring after The Jump.

BIKERUMOR: What led you to Sugar?

JUDE: I was a bike tour guide. That’s what I was before this. I graduated college, I was a wrench in a shop for a little bit- anything so that I could travel 3-5 months out of the year. 20’s are for learning. 30’s are for action. So I did a lot of traveling by bike. You know when you’re in your 20’s and you’re still glossy-eyed about the bike industry? I still am- I still love the bike industry, but it’s just different from this end of things. At that time what I thought I wanted to be a lifer. What would I do? What would my contribution be? It sounds so cheesy.

BIKERUMOR: And if you’re a bike tourer, wheels are really huge.

JUDE: I thought, ah, if I could be a wheel builder that would be the awesomest thing. So I set to work. My team was on my side, thank goodness. Looking back, I don’t know if Sacha would think this or anyone who started any kind of a business would, but it is a million times more hard work than I’ve ever done.

BIKERUMOR: And this was six years ago?

JUDE: Yeah. I started in a 64 square foot studio in southeast Portland. So customers literally waited in the hallway. I didn’t actually think I’d have customers…

BIKERUMOR: So this particular model of building, approaching wheelbuilding as a tailor, was that something you set out to do immediately?

JUDE: Not immediately, but in the industry you either need to commit to doing it or not commit to doing it. I had to commit to doing it and I decided what that would look like for me, what that ideal situation would be.

BIKERUMOR: Who do you partner with?

JUDE: Vanilla, Breadwinner, a little bit for Sweetpea, Argonaut, and a couple smaller builders every once in a while. It’s kind of where we want to cap it. Just a couple builders. And then we deal with the general public.

BIKERUMOR: And you have this awesome “tasting” program for testing wheels for consumers.

JUDE: The concept behind that is that you’re spending a lot of money and handbuilt wheels were, at least this was my impression I was getting from people, are outdated and slow. That they were going to be heavy. And I really wanted to showcase that handbuilt wheels could not only be sustainably built and easy to repair but that they could be performance oriented.

So we use it to understand what a person’s recipe is because there are so many factors like cadence, bike, weight, power output, all those kinds of things. So we want to match a wheelset to what that person’s expectations for performance and durability are. And sometimes, oftentimes, aesthetic comes into play as well. Even for the people that say they don’t care.

BIKERUMOR: I mean, if you’re set up with every color spoke nipple as you are, why not? So you have several sets of wheels in your wheel “Tasting Room” that people can try –

JUDE: That process is a long process sometimes. Getting someone into the right stuff, but it’s great.

BIKERUMOR: When you have a set of wheels that you give out, what are the differentiating factors? What are you trying to demonstrate with those wheels?

JUDE: Sometimes we’ll build something up and we’ll just change the spokes on a particular build. We kind of characterize things into different types of hubs. Pawl-style engagement hubs, Shimano-style engagement hubs because really it’s impossible to build every type of configuration for the demo program. But we try to get that kind of dialed. And we use butted spokes versus bladed spokes- that’s a really big factor. Is that upgrade worth it or not? But it also allows us to stay in touch with whether these things really matter so for people who won’t do the demo program, how we convey that information to them.

On the science side of things, I work with an Engineer who is my mentor in that department, and we are now partnering with a metallurgist in the area to help understand spoke metal life and fatigue as an independent study from what manufacturers are telling us. All that stuff is happening in the background so that at this small council chamber we have all the information we need.

It’s hard to build wheels for people – it’s easy to build top shelf wheels for people because you just pull all the nice stuff. It’s a lot harder to build wheels where people come in with certain parameters, budgets or performance or preferences whether they are real or not in terms of a particular hub or spoke. Tailoring around those things can be a little bit tricky. But it’s more fun. It keeps it interesting, so I like that part of it.

BIKERUMOR: And you have wheel building classes. Where did those come out of? Where was the need?

JUDE: People asked for it. And I enjoy it when I do it only four or five times a year.

BIKERUMOR: How often do you do them?

JUDE: Four or five times a year. I used to do it a lot more frequently but with the stress of wearing a lot of hats all the time, I’m most effective when I’m present, we all are, right? I was finding I wasn’t as present for some of the classes. And it’s more fun when I’m into it.

BIKERUMOR: How many wheels come out of here in a week, if you’re cooking?

JUDE: If we’re cranking I can handle building… it’s hard because we get walk-ins a lot and I have to answer the phone. If I’m building solid, it takes 20 to 45 minutes depending on the type of build to build a wheel, most in the 20 to 30 minute range. If we’re really cranking I can do eight wheels in a day. But by myself, I can finish six today. And they all have to pass the same QC testing.

BIKERUMOR: You perform your own QC.

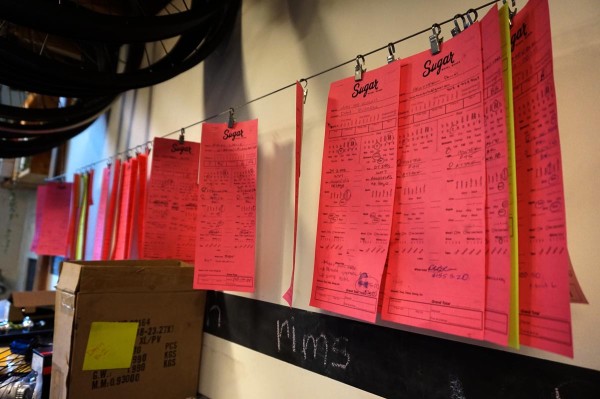

JUDE: We have to record everything. What’s really cool is that we record the tensiometer, when it was calibrated. Then we measure and record the tension of every spoke. And then you have to sign, that’s a big thing if all of this gets logged into a wheelbase, then if a wheel comes back with a broken spoke, we look at the spoke, which we will also take the metallurgist to actually see what’s happening with the spoke to see where it is fatiguing. We also look at the notes to see if there are any notes about the build, who built it. There is a sense of accountability and ownership built into it that I think is really important.

BIKERUMOR: That’s next level stuff.

JUDE: And then each person who gets their wheelset gets a certificate of build with the builder’s signature- a letter-pressed version of it.

BIKERUMOR: So you are affiliated with this emerging Komo Rebi [women’s adventure] team. So what is your involvement with that?

JUDE: My involvement is in the sponsor level. What attracted me to it is it is well-organized and it has the potential to inspire other women. I want to be a resource for learning about the bike and build a connection with this vehicle that’s going to take you to adventure. Because a lot of what holds women back from adventuring is this fear that isn’t real… I mean, it is real. The first week you go bike touring or off road riding or something like that, you want to make sure you have enough food and everything like that, but it’s not as scary as people make it sound.

BIKERUMOR: The women who are doing these big epic bike packing tours and they are more concerned with the other guys on the trail than their own freaking gear.

JUDE: Totally! And that’s a real concern. I really like the idea. I like the crew that’s coming together. Hopefully some positive things will come out of it. I really like the coordination of all the people coming together for it.

BIKERUMOR: You’re doing a wheel building class with them?

JUDE: Yeah! It’s going to be so fun. These women are going to be really badass. It’s something I really wanted to do as a sponsor. I’m looking forward to teaching it. So I’ll be teaching six times this year. Maybe I’ll join them for a trip.