OK, so, technically this new Lauf Cycles rear hub design could have “thousands” of points of engagement per rotation, but that might as well be infinite. Also known as instantaneous.

Either way, the effect is that the hub will engage so quickly that it will feel immediate, and it does this with a very clever staggered, potentially “elastic” pawl design that also softens engagement and can be located throughout the hub’s entire shell.

Oh, and it does all of this without magnets or springs.

How Lauf’s hub design works

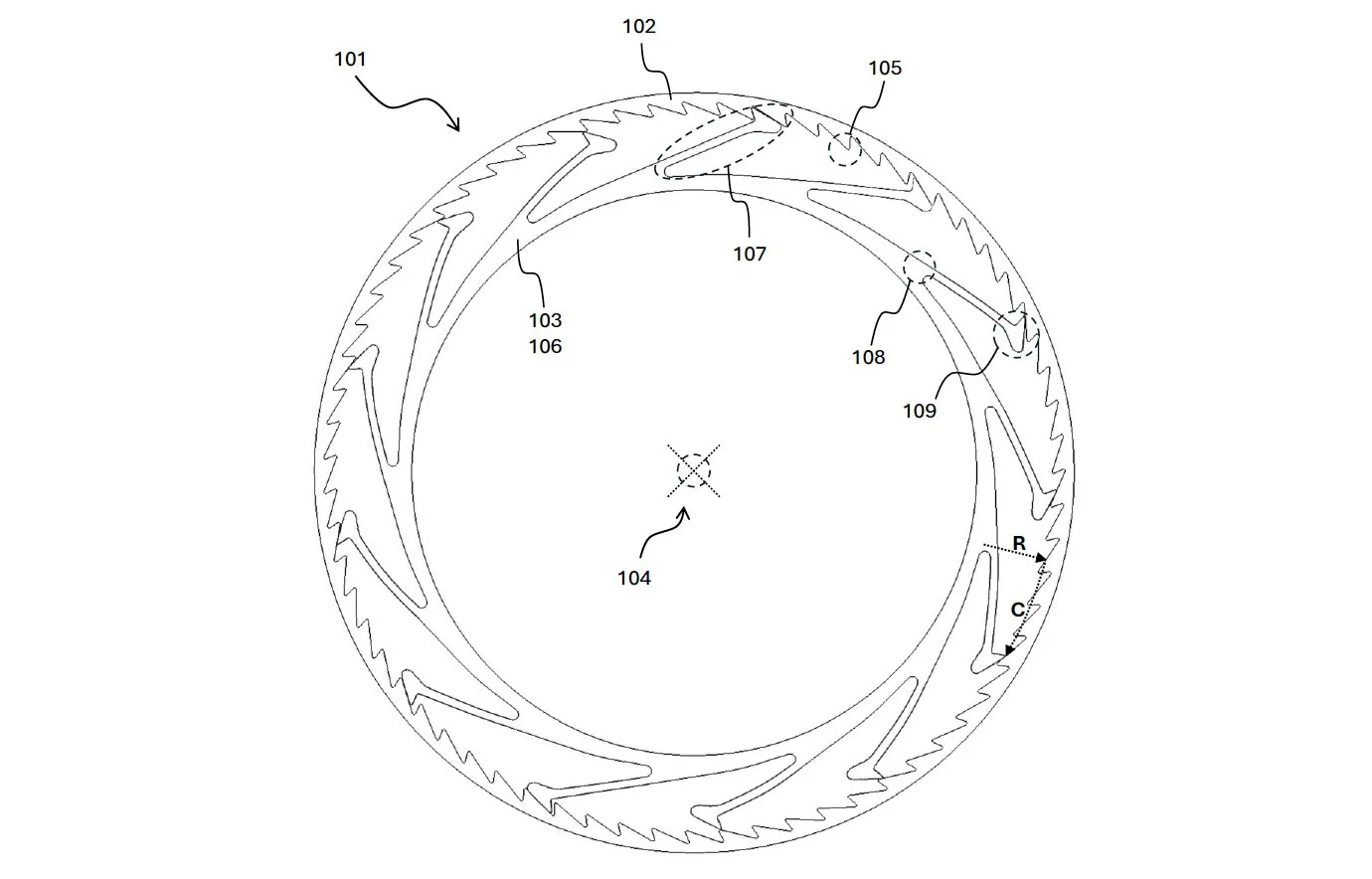

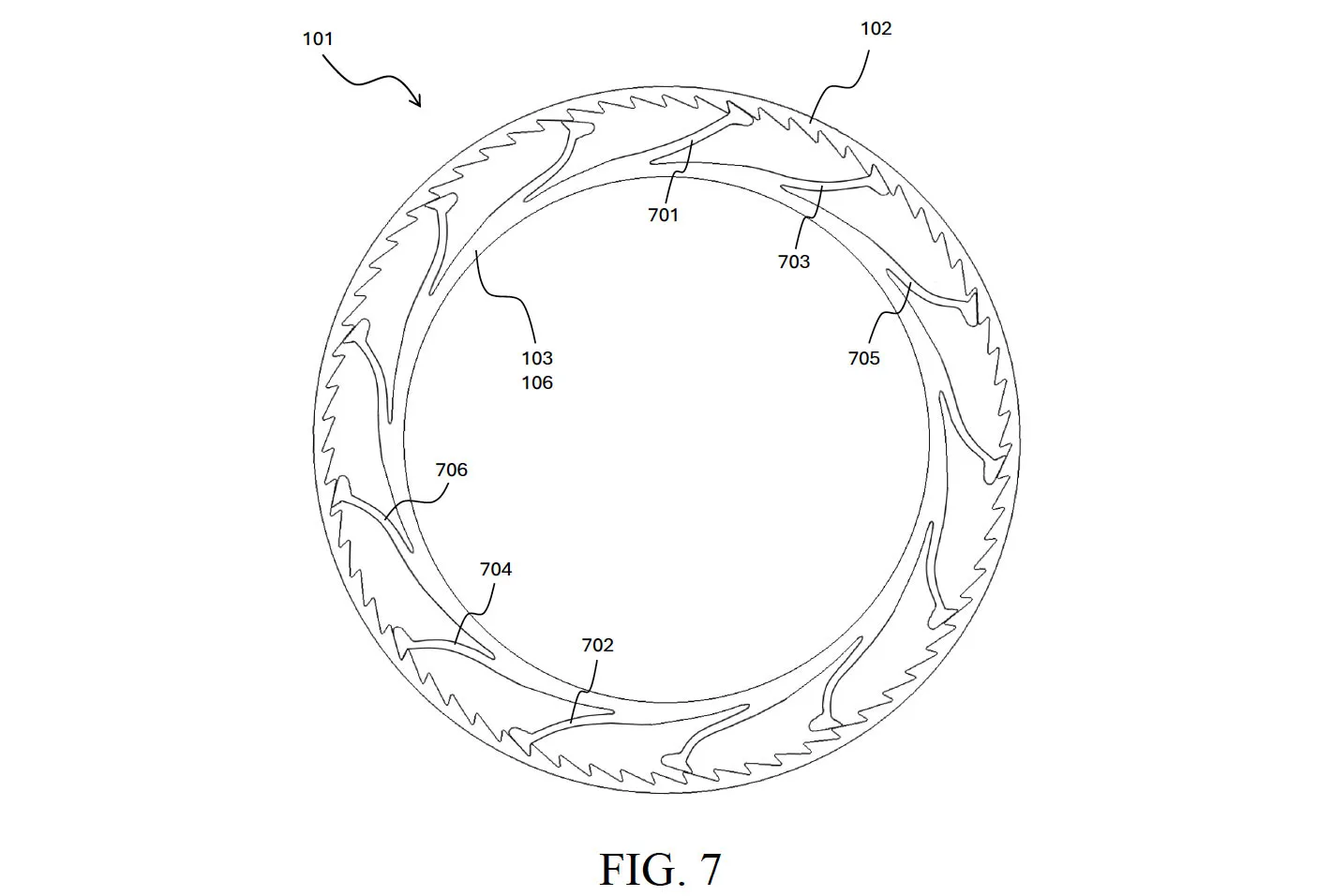

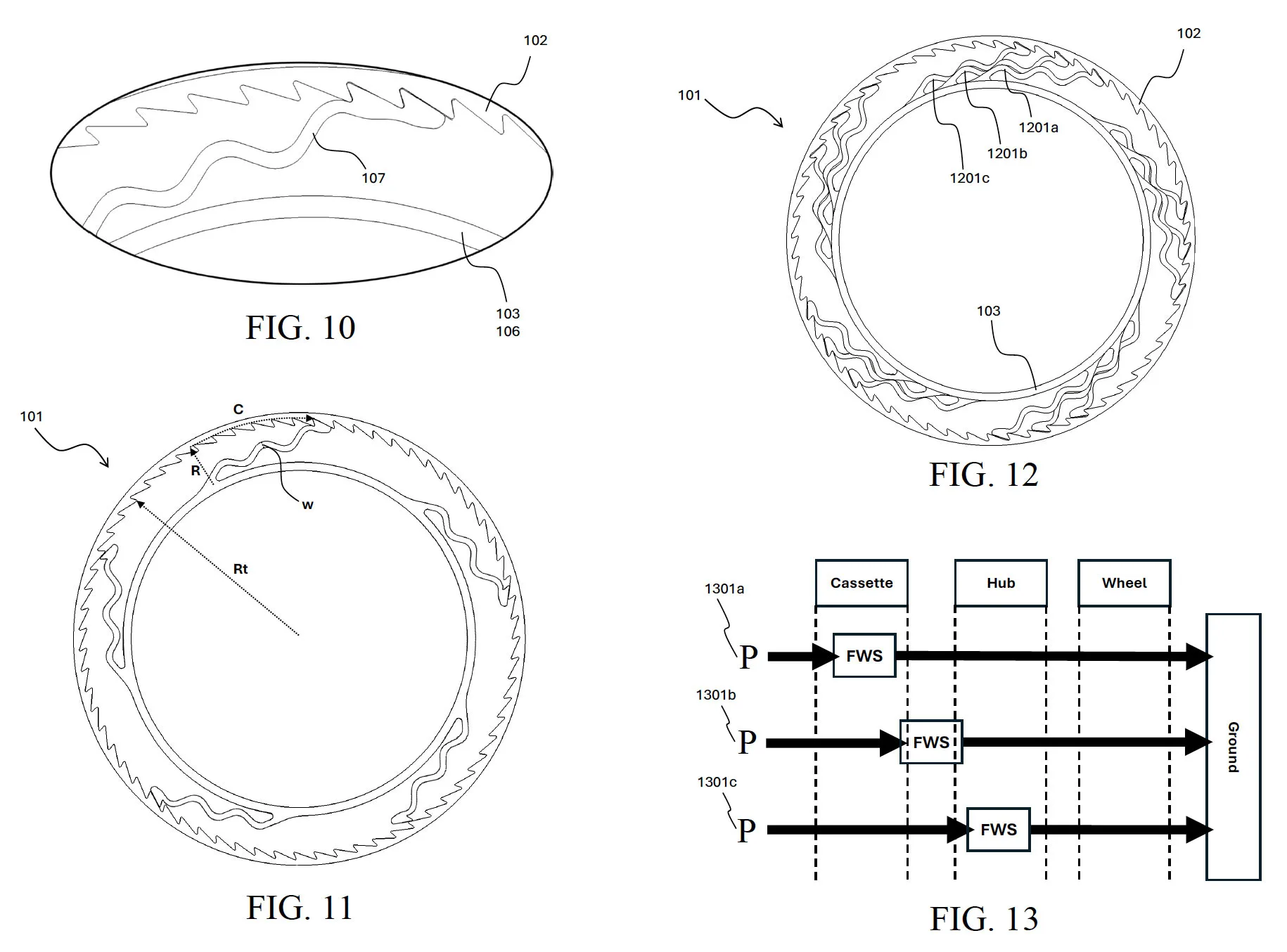

The basic premise uses integrated pawls (701) made on an inner ring, each essentially its own spring with a toothed hook at the end to engage with the teeth (105) on the drive ring (102).

However, it could also place the pawls on the outer ring and put the drive ring on the inner surface:

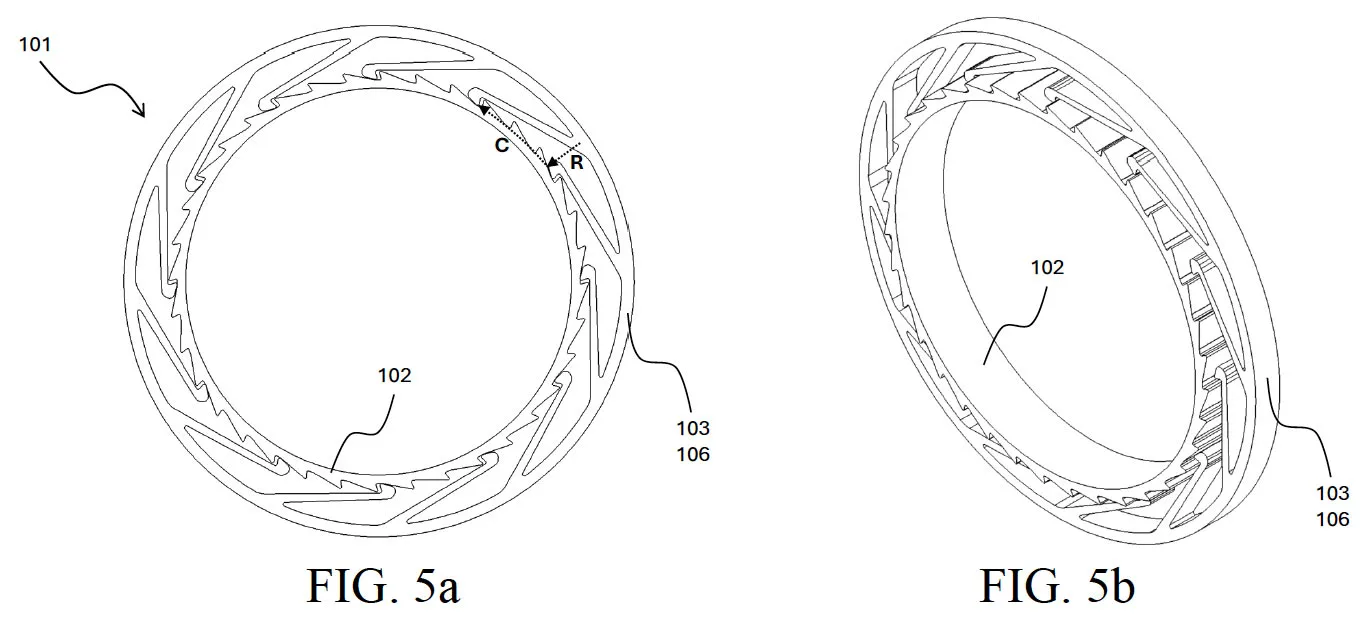

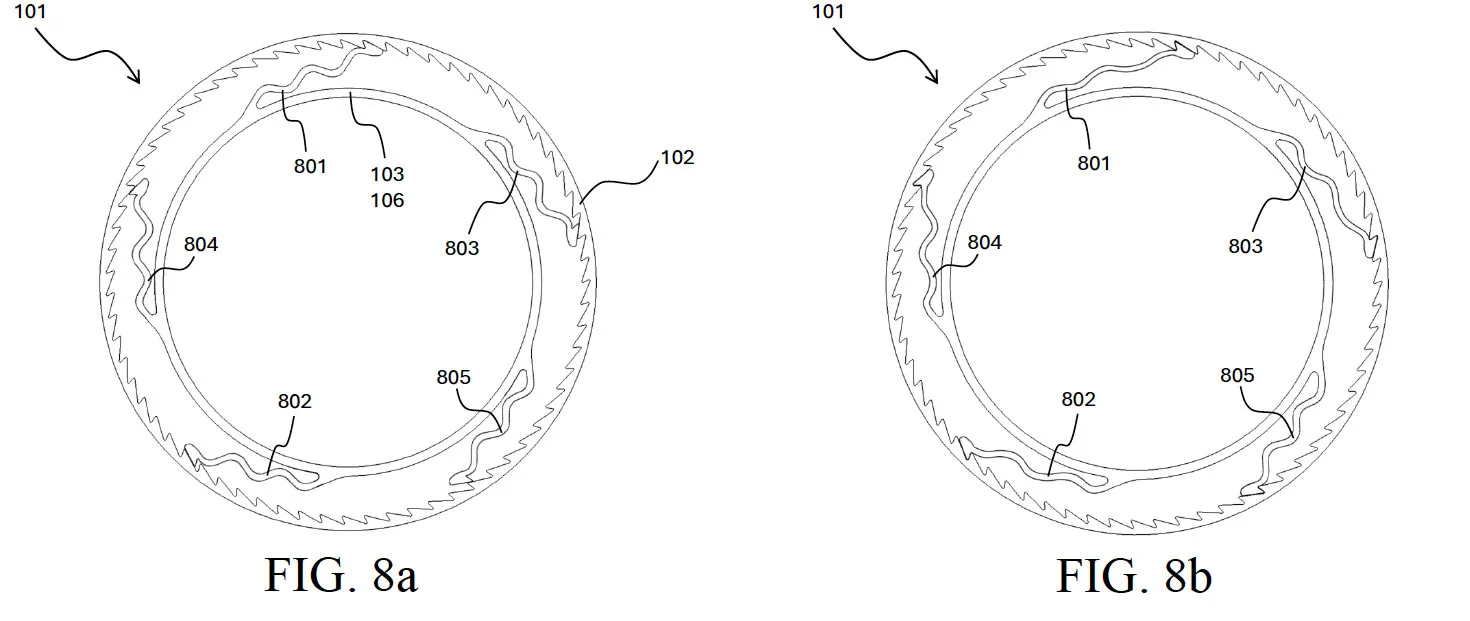

The pawls are staggered to engage at different points in the hubs rotation, effectively creating more points of engagement with fewer-but-larger teeth. This is how many current hubs work, usually having two or three pawls engaged at any point in time. For hubs that don’t need ultra-quick engagement, the pawls could be wider (Fig. 5b).

For quicker engagement, a second set of pawls could be offset from the first set (blue & orange image on right). Or…

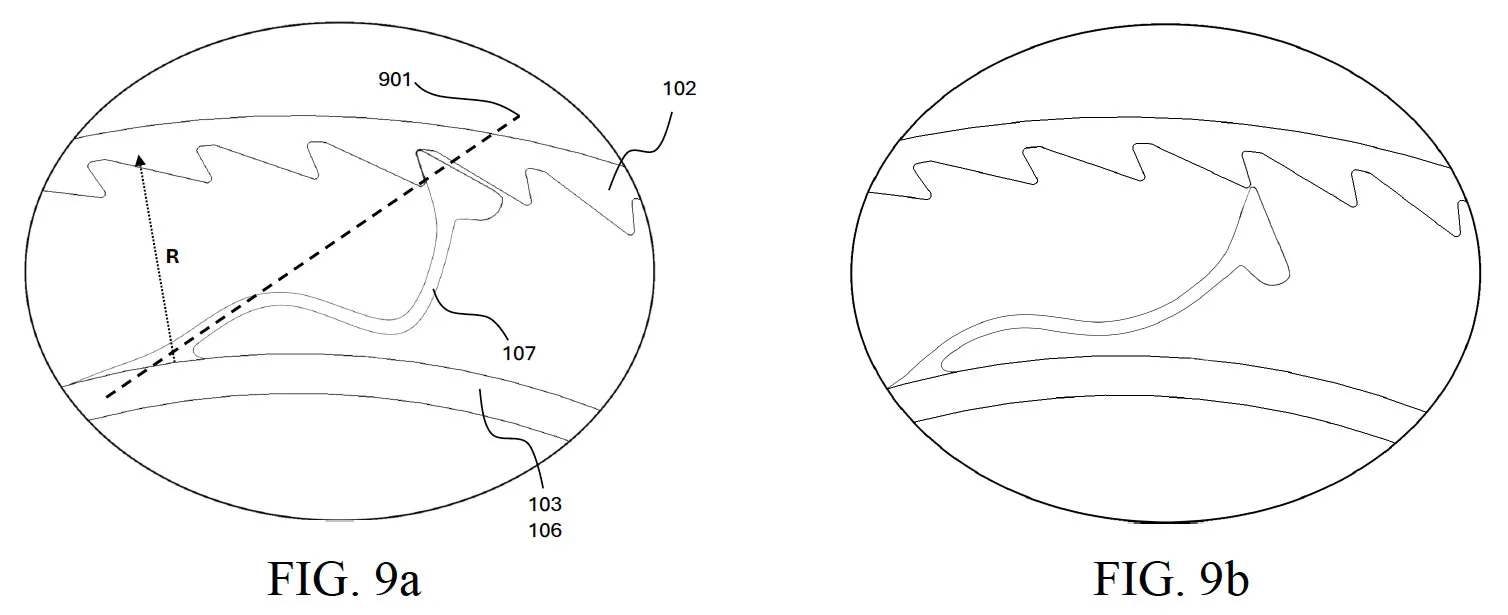

…they could even use three sets for even faster engagement (Fig.12). Alternatively, they could use two or three rings in sync to increase strength because, admittedly, these pawls would have to be pretty thin to fit into a traditional hub design. Assuming that’s what Lauf has in mind, let’s stay on that track for a moment.

Stretchy, Wavy Pawls

Another tactic for improving total engagement and strength is to use a wavy shape, allowing each pawl to “stretch” slightly, just enough such that one set engages first, then they stretch until the second set engages, then those stretch until a third set engages.

The benefit to this is that you have more engagement all the way around the hub, reducing lateral stresses between the cassette and freehub and hub shell.

And, assuming you apply too much torque, that wavy design allows the pawl to breakaway before it snaps. No, that would not be pleasant for you, but it would theoretically preserve your hub. However, take a look at Fig. 13 above for a second, and then scroll down…

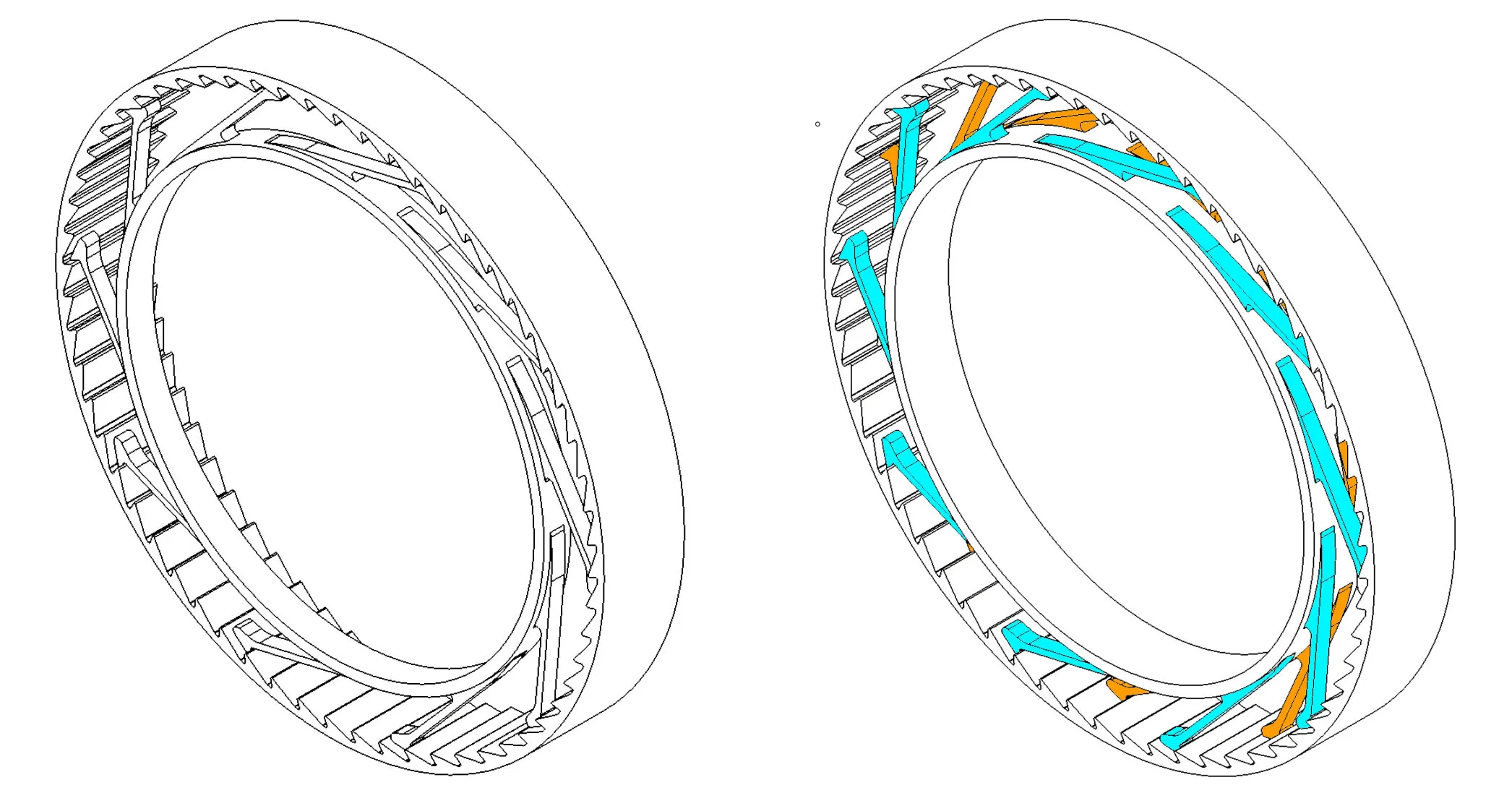

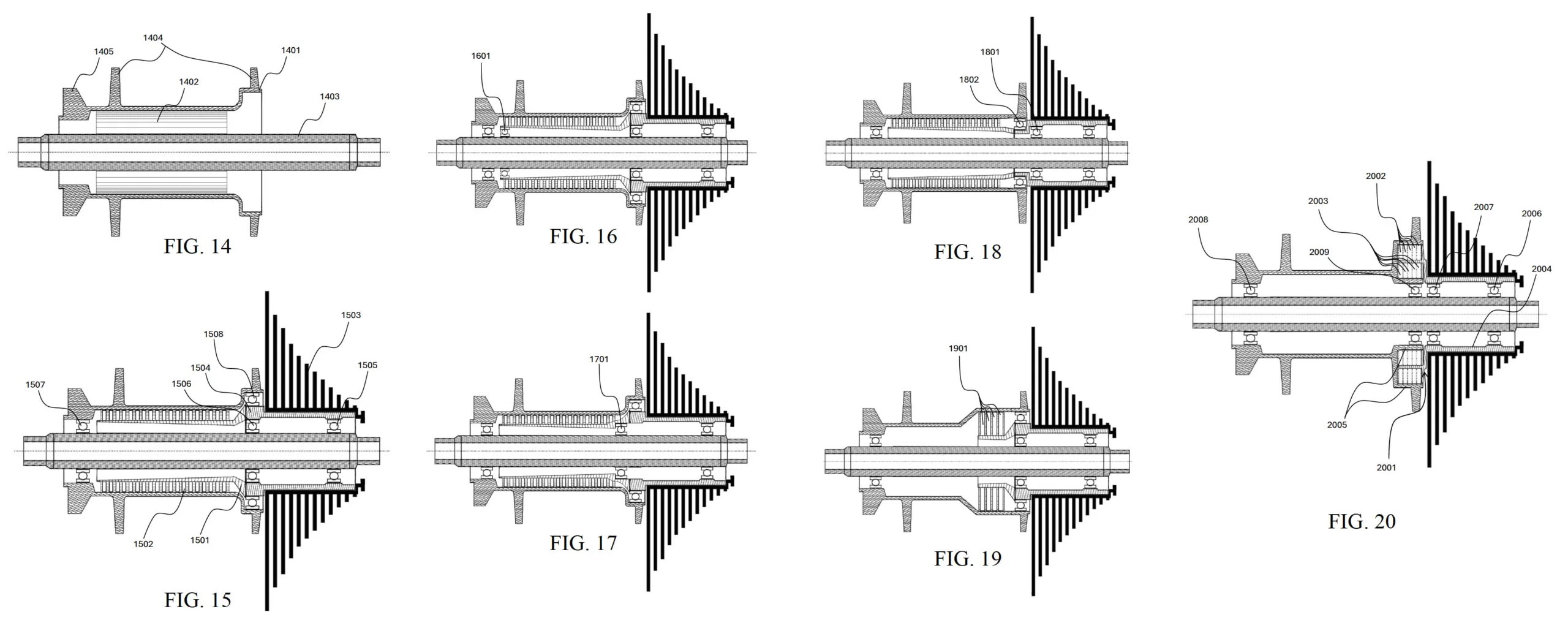

Thousands of Pawls, Full-Width Freehub Bodies

What if you filled the entire hub shell with rows of pawls, providing a massive amount of contact area, each slightly staggered but also able to stretch to allow other rows of pawls to also engage?

Not only would this create insanely fast engagement, but it would provide insanely solid engagement, too. Lauf says this also provides a much greater tolerance for pawls and ratchets being out of sync, which they say often are due to real-world manufacturing limitations.

And, because it allows for a full-width freehub body that’s essentially a second axle, it would make the entire assembly far more robust, too. Figures 15-20 show a variety of design options where multiple rows of pawls fit in various places and allow for a wider variety of freehub-to-hub shell interfaces.

Lauf also says the “stretch” of each pawl allows your power to come on gradually (still very quickly, mind you), which eliminates that loud KLUNK, particularly on hubs with lower engagement speeds. This may actually reduce wear and tear on your drivetrain, too.

While Lauf is known for their bikes and forks, they’re always tinkering. Their likely goal is to license this design rather than become a hub brand, too, but we’ve been surprised by them before, so who knows?