Last summer, Easton completely revamped their wheels with the all-new Echo hubs and RoadTubeless rims. The news led with their carbon versions, but the EA90 SLX was the sleeper of the bunch. It packed all the new tech into a svelte, strong and light wheelset that could go from training ride to crit to ‘cross with ease.

After about four months of use in all manner of weather, I’m happy to say the wheels work as good on the road as they look on paper. With road tubeless compatibility outta the box (no rim strips!) and smooth rolling, durable hubs all on tap, that’s saying a lot. The 1,400g claimed weight ain’t too shabby either, and the entire test was done under my 6’2″ / 188lb person. Check out the details, actual weights and tech notes below…

With valve stems installed, actual weights are 809g rear, 631g front and 141g for the skewers. That puts them at 1,440g with the valve stems, close enough to the claimed weight considering that’s probably without the stems.

What makes that weight even nicer is that no rim strips will add to it. The sealed alloy rims make tubeless set up foolproof. That’s possible thanks to Easton’s dual threaded nipples, which thread into the rim insert while also threading onto the spoke. They’re the only proprietary part of the system, though they true and service like normal. Spokes are standard Sapim straight pull, double butted pieces and bearings are standard, too.

The inside profile doesn’t hurt either, with a nicely rounded center channel and bead socket grooves to hold the tires in place once inflated.

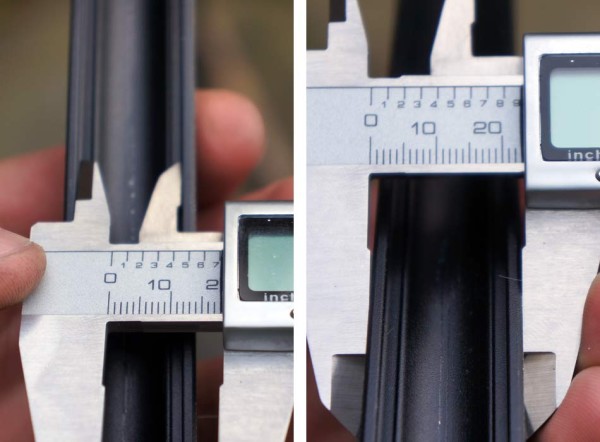

Claimed measurements are 17.5mm internal/22mm external. My test set came in closer to 18mm/23mm, which is a welcome bonus. Height is 25mm with a rounded-to-flat semi-aero design.

Front hub has 16 radially laced spokes. On both front and rear, the spoke head is trapped under the shell with a silver ring, and they’re pushed about as far out as you can take them without affecting frame or drivetrain clearance.

The rear hubs have 20 spokes laced radially 1-cross on the non-drive side and 2-cross on drive side. The freehub body

Check out this post for details on bearing placement and internals. Essentially, the Echo hubs use much, much wider load bearing placement than standard hubs, pushing the drive side one almost 2/3 of the way out the freehub body. The idea is to give them a more stable platform and reduce the leverage drivetrain forces have over the bearings, which can degrade longevity.

The freehub has machined holes and slanted, truncated slides to catch the cassette. Not only does it look good, but it’s also held up to a Shimano cassette better than most:

Note the minimal scarring on the face of the grooves. Also note the slanted face on most of the grooves, helping save a few grams.

The gray rubber seal hides the teeth and pawls, the latter being installed into the hubshell. That’s reverse of most hub’s designs, and it’s what allows them to push the load bearing out into the freehub. One caveat: tug the freehub body too hard and it’ll pop out. It’ll also wiggle in/out a bit with the cassette on there until you get it clamped into a frame.

Features and weight are all good, so how ’bout performance?

In short, it’s very good. They roll smooth, are reasonably quiet and are surprisingly stiff for a lightweight wheel. In fact, I could just say they’re remarkably stiff. Period. No lightweight qualifier necessary. Beyond hitting high speed turns, sharp maneuvers and all-out standing sprints, an easy way to test wheel stiffness is to lean the bike to the side as much as possible. Yes, that’s what’s going on in the picture on the left, and yes that’s what it looks like when you lean the bike as far to the side as you can. It seems way more precarious on the bike, I’m quite disappointed in how it really looks. It’s the equivalent of the camera adding 10 pounds. Except in this case, I feel like it’s losing 10 degrees of lean.

Regardless, it’s a good test, and the EA90 SLXs passed with flying colors. Virtually no brake rub at the biggest lean angles I could muster. That’s mirrored in more practical applications like cornering, or high speed transitions from one pitch to another (think coming down a mountain road and turning onto a flat cross road. After plenty of whipping around, running off the road and slinging through corners with a few bunny hops thrown in, the wheels are remarkably true. Not 100% true, but very, very close. Close enough that I had to dial the brakes in and spin the wheels to notice…it wasn’t perceptible on the bike.

When they arrived, the weather was still warm and sunny. Since then, we’ve had plenty of freezing cold and wet, sometimes simultaneously. The hubs have held up very well through it all and show no signs of needing maintenance.

I’ve tested them with both Hutchinson Intensive and IRC Formula Lite tubeless tires, both using Cafe Latex sealant. Both mounted up easily without a compressor and have held air respectably well…good for several rides before needing a little top off.

My only complaint is the braking surface. It’s a machined surface, but it’s pretty smooth. I’d like to see them have more bite. There’s a subtle but detectable drop in stopping power going from Shimano’s wheels to these with the same brakes and pads.

Normally, I’m not very excited about alloy wheels. It’s carbon for me, baby. But these are exciting. Weight’s comparable to similarly sized carbon clinchers, but price is just $1,200 for the set. Not super cheap, but that’s $500 less than their heavier EC70 carbon/alloy wheels. They’ve made a great all purpose set of wheels that are light enough for racing. And Easton says they’re tough enough for cyclocross, too (we plan on testing that next). In other words, they could be the only wheelset you’ll need.