Boo Bicycles has been making carbon fiber-and-bamboo bicycles for years now, but they keep refining the process. The latest iteration becomes the new premium SL offering, which not only drops weight from the frames, but makes them stiffer and stronger, too.

Above is the new SLG top-level gravel road bike, and this one’s built for Boo’s Nick Frey to race at this year’s Dirty Kanza and Crusher in the Tushars.

The upgrade is a new way of forming the top and downtubes. On their normal tubes, they hollow out the bamboo. On these, they hollow it out even more, making it lighter, then an S2 fiberglass load dispersion material is placed on the inside of the bamboo tubes and is cured while under compression from the inside. The result is a tube that’s much more impact resistant. Frey told us there tends to be a lot of downtube damage on composite frames in events like the Dirty Kanza, coming from really sharp gravel flying off the front wheel. Frey says they took a normal bamboo tube and smashed it on a table corner and it cracked, but repeated blows with the new S2-enhanced tubes didn’t show any damage.

But those aren’t the only changes growing on this bike…

This one’s made with aggressive, racing geometry and 700×42 tire clearance. But all of those metrics can be whatever you want, they’re all made custom. You could even build it for belt drive, or choose between mechanical or electronic (or both) groups.

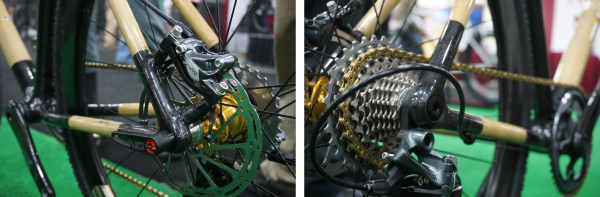

The other big new feature debuting on the SL models is it’s their first thru-axle design, which stiffened up the rear end enough that they could eliminate the seatstay bridge.

It’s built around a Santa Cruz Bicycles’ rear derailleur mount and Syntace X12 thru axle. They use a dummy axle during construction so they can mold the rear dropout structure directly around the hanger, so there’s no extra metal used in the dropouts, it’s all bamboo and carbon fiber. The only other metal on the frame are the water bottle bosses.

It’s also their first post mount brake design, which further cleans up the bike and drops weight.

The SL moniker will refer to all top level bikes, and they’ll only be available as full custom. This one’s the SLG, for Super Light Gravel. There’ll also be an SLX (cross) and SLR (road). Retail is $4,495, a thousand dollar premium over the standard bamboo and carbon frames. This brings with it a stiffer carbon layup, too, making the front end laterally stiffer. All told, the thru axle dropouts save about 80g, and tube saves about 100g, but you add a bit back with the actual thru axle compared to a QR skewer.

The gravel bikes will also get a smaller diameter seatstay to add more compliance. That wasn’t done on Nick’s bike because he’ll be doing a lot of road riding, too.

Another cool thing they figured out with this build was that you can hack XX1 rear derailleurs to work with CX1 drop bar shifters. Nick wanted the wider gear range for the Crusher in the Tushar, where there are bigger climbs, but the CX1 rear derailleur won’t clear the larger cogs on an XX1 cassette. But, the XX1 derailleur’s movement didn’t jibe with the CX1 shifters…until they found you could determine the pull ratio by putting the CX1’s derailleur cable loop and mounting it on an XX1 rear derailleur. By swapping that piece (the black plastic bit that the cable wraps around between the adjustment bezel and the derailleur’s pinch bolt), you get the XX1’s bigger pulley offsets with CX1 shifter compatibility.

The one above is shown in stock formation, but he’ll be switching things over based on the next race’s elevation profile.

They also figured out you can combine XTR Di2 shifting with an XX1 cassette and get the best of both worlds: crisp, motorized shifts with a wider range cassette.

They said it worked perfectly with no modifications to either group’s parts.

Below the SL is the RS, which uses the standard alloy dropouts, regular seatpost, no internal Di2 wiring, and is offered in stock sizing.

The beauty of custom is you can get things like this awesome monster crosser/off road touring bike.