Don Walker has typically shown two things: Cyclocross bikes and track bikes. There’ve been variations of them, but those have been his bread and butter for years. They still are, too, but this year he brought a little more variety to the show with a brazed gravel road bike and several aero bikes, all fashioned from steel, of course.

Above and center, though, is a candy apple red ‘cross bike that keeps the traditional flame alive with cantilever brakes. Beside it is the gravel bike, which also sticks with rim brakes, but at least in a more powerful iteration. Regardless of the stoppers chosen, the bikes look as good as ever, as do some amazing steel road bikes from two other builders we’ve not seen before…

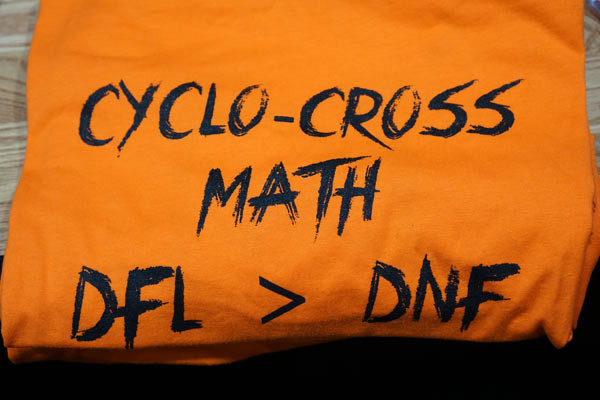

Perhaps the best ‘cross shirt at the show. Maybe the only ‘cross shirt at the show, too.

This steel fillet brazed gravel bike was simple, yet beautiful. It’s for one of the guys that was helping work Don’s booth while he was busy with other important work. You know, like running the NAHBS show, which was stellar this year.

You don’t see many aero steel triathlon bikes, but this one looked sharp in all black with deep/full carbon wheels from HED.

This colorful number was meant for beating the clock in the velodrome. Check out our pre-show interview with Don for the scoop on what he’s building now and more about NAHBS itself.

EQUILIBRIUM

The Equilibrium Pegasus had us fooled at first glance. Does it look like a steel bike to you? The curved tubes and smooth, heavily shaped junctions looked more like carbon. Enough so that they even drew this sign that invited a second look:

It was entered into the Custom Campagnolo contest.

Equilibrium does mostly lugged steel bikes, but they’ll now offer this “molded” steel frame as a custom option, too.

MANDARIC

Despite the exotic sounding name, Mandaric bicycles are actually from California. They build in a variety of steels, plus composite and scandium, and even blends those. The TIG welded Niobium shown here is a new model for them and made of Niobium Steel tubing from Columbus. It’s not just the tubing that made it special, there’s a lot of great detail work here.

Full internal cable routing enters the headtube for the rear brake and both derailleurs. The rear shift cable pops out on the lower third of the seatstay, just in time to form a clean curve into the derailleur. Hit the link to seem their studio shots of this bike for more.

This was the cleanest BB install at the show. Pressfit is nice, but when you can form the BB shell to fit stock Campagnolo bearings? That’s special. The cutaways to show the internal carbon sleeve is just icing on the cake.

That design makes for a very wide BB shell, which let them push the squared chainstays out to the limit for a massively stiff frame that still benefits from steel’s ride qualities. Note that you don’t see the front derailleur housing or cable anywhere under the downtube or BB shell, it only pops out on the backside just in time to run a clean line to the mech.