Co-Motion’s been building tandems for quite some time, so it should come as no surprise they took home an award this year.

What was more of a surprise was not one, but two different gravel-style road bikes with alternative gearing designs. Usually we’ll see those with larger collections show off one bike with something like an internally geared hub or gear box, just to show what they can do. Co-Motion had both, and both were fine examples…

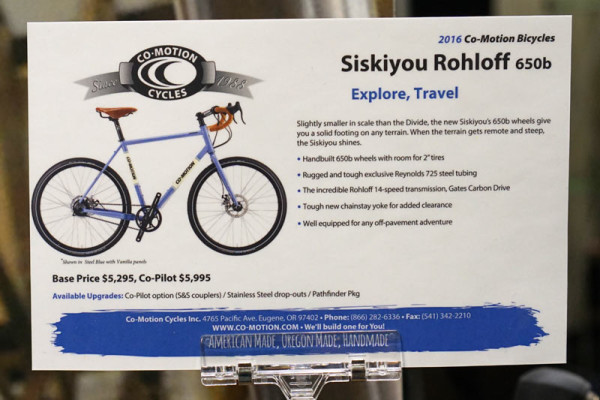

The Siskiyou Rohloff 650B puts a Rohloff 14-speed internally geared hub on their Reynolds steel adventure bike, setting the twist shifter inboard of the handlebar tape. It’s driven with a Gates Belt Drive, and between the cogs is an all-new chainstay yoke that improves tire clearance.

It uses a similarly clever cable routing design as the new Divide Pinion:

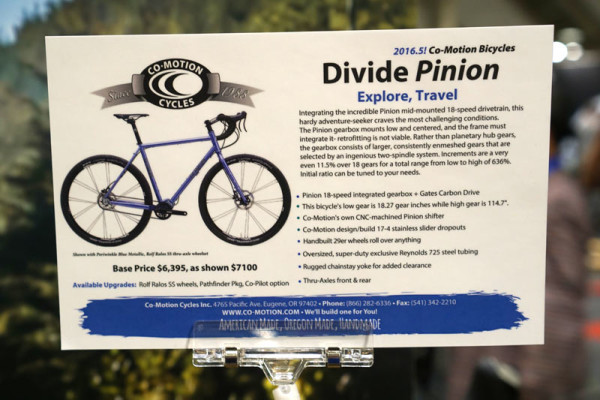

The Divide is their 29er drop bar travel and adventure bike, also made of Reynolds steel tubing.

This new Divide Pinion replaces standard gears with an internal gear box providing a whopping 18 speeds.

A modified twist shifter controls the gearing…

…with two sets of coupled cables running along the down tube. They had to switch each cable’s position in relation from the shifter to the gear box, and the cable couplers make that possible.

It’s all making things turn through an oversized Gates rear cog and Co-Motion exclusive stainless steel sliding dropouts.

This racy number took home the Best Tandem award for NAHBS 2016 thanks to a super clean, high end build, excellent paint and solid construction.

The Java 29er tandem may have big tires but gets FSA road cranks and Ultegra derailleurs. Rack and fender mounts adorn the zonally butted tubes. Retail is $5,395.