Kent Eriksen is in rare air having taken home two awards in a single NAHBS show, but 2016 was his year. He won best in show for Cyclocross and TIG welding, and you’ll soon see why.

The titanium cyclocross bike shown above is a pristine example, but at first glance it’s another titanium ‘cross race bike that uses modern standards like a 44mm head tube, disc brakes and thru axles. But, as usual, the devil’s in the details…

To be sure I didn’t miss anything that made this an award winner, I simply asked Kent “What makes this bike so special?”

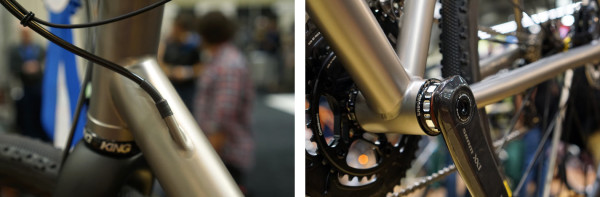

The answer isn’t anything crazy, it’s really just a matter of clean, perfect execution of the small things that make it one of those bikes you keep for a lifetime. The welds are flawless, the finish perfect, etc., etc. On to the details… Starting up front you notice a hydraulic brake hose feeder tube with rubber seal. Others use tubes to route the cables or hoses through the frame, few take the time to seal the hole. Then, the hose remains inside the frame all the way through the BB shell…

…and out just in front of the caliper, on the inside for an immaculate appearance.

Same for the Di2 wire, which runs through the top tube to the seatpost battery, then down past the BB and into the chainstay. And those are big, 1″ chainstays to create a stiff platform on which to power through the mud. It’s hard to tell, but there’s subtle shaping to them, too.

The flat mount brake mounts are cut into the chainstay, and a chain keeper tab on the driveside takes (a little bit of) the misery out of a wheel change.

This bike, built up as shown and with their very clever MTB-to-Road crank spider adapter, would run about $10k.

This bike and others in their range now use Eriksen’s new machined thru axle dropouts.

This monster crosser shows a bigger, more aggressive take on the cyclocross bike. It, too, gets the offset spider to run a double road chainring set on a SRAM direct mount MTB crankset.

Erikson, like Mosaic and others, is now offering a hole-free eTAP specific build for his road bikes.

His second award was for best TIG welded frame, which was welded by in-house builder Brad Bingham. It went to this full suspension mountain bike, which is pure eye candy:

Congrats, Kent!