English Cycles never disappoints, always showing off some of the most creative bicycles and designs at NAHBS. This year, though, he really stepped it up, bringing an updated version of his Project Right one-sided road bike with modular hubs that lets the same wheels be used on front or rear of the bike. And his travel bikepacking plus-tire mountain bike, with clever bag management features and packing-friendly designs. And so much more…and we have video!

English Cycles Project Right

The bike gets a second look once you notice the missing fork leg. Then the missing non-drive chain- and seatstays. And then you notice that the brakes and the drivetrain are all on the same side. But that’s just the superficial stuff. Check this video for the full run through of it and two other amazing bikes, then we’ll move on to more pictures:

Now for the photos and a couple other bikes…

The main update to his Project Right concept for 2019 is the use of a custom hub design that allows for the same wheels to be used front and rear. The hub’s center has a tri-lobe shape, which is commonly used in industrial applications and has been proffered for a replacement to the splined freehub body over the years.

This means the outer hub shell with the spoke flanges need only slide over and bolt onto it. The other trick in such a design is eliminating the torsional stresses a one-sided frame could allow the drivetrain to put on it. To solve that, he put the belt drive cog on the outside of the tubes, running the axle through where the dropout would normally be. The brake rotor is out there, too.

This isn’t the first time Rob’s made his own hubs – check out these aero road hubs from an earlier show.

English Cycles Travel Mountain Bike

Rob’s a fan of long distance, multi-day rides and events. For mountain, he built this travel plus bike, able to keep short chainstays despite big 3.0 tires. A few things make the bike more packable, letting it fit into a standard case to avoid oversize fees. First, the rear end unbolts from the front triangle, using two bolted attachment points at the bottom for more stiffness, and a single bolt up top.

The other bit is a hinged stem face plate, which makes it much quicker to get the handlebar off. But there’s a lot more going on with that stem.

The truss fork was designed so that the front bits wrap around the roll bag, keeping it from bouncing around.

More road bikes…

This steel road bike was over at Alto Wheels’ booth and showcases English’s trademark thin tubes and elegant form factor. It also shows off Alto’s XDR hubs, which is available soon.

This endurance race bike is his rig for long-distance road.

Note the hourglass shape of the head tube and brazed tube joints.

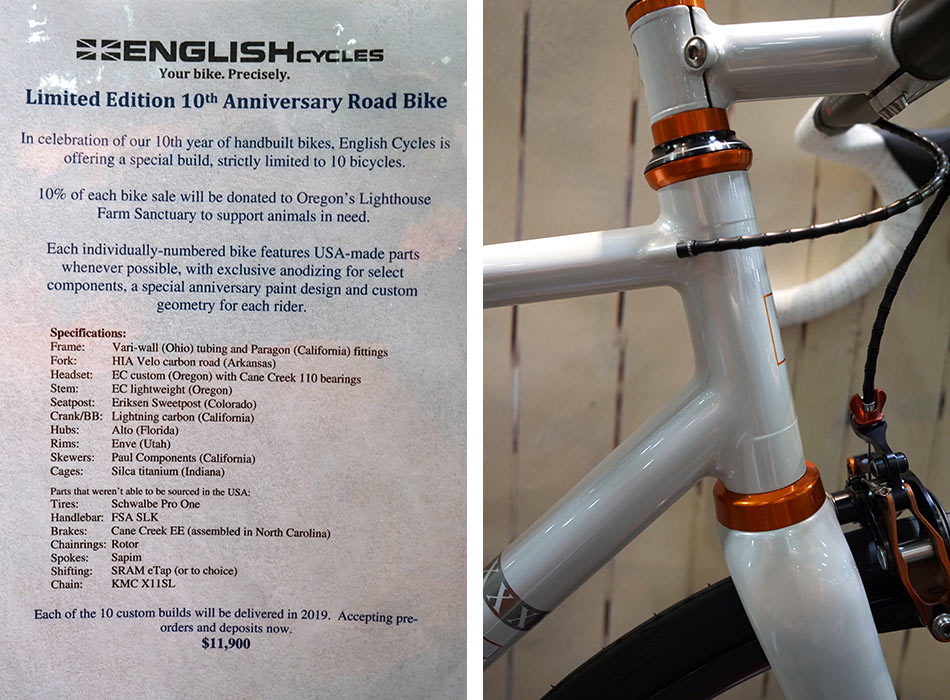

10th Anniversary English Cycles Road Bike

Rob English is celebrating 10 years with a limited run of these classic road bikes. He explains the concept in the video, but left out a couple of cool details.

Since most modern carbon road bike forks use a tapered headtube, many builders have gone to the oversized 44mm head tube. Which on a classically thin-tubed steel road bike looks terribly out of place. But that wider fork crown has to fit somewhere, so Rob machined his own lower headset cup to add the necessary diameter for HIA Velo’s tapered carbon fork, which has a molded carbon crown race designed to fit the Cane Creek lower bearing.

SRAM’s drivetrain may not be made in the USA like so many of the other components on the bike (including the tubeset!), but at least they’re a U.S. company.

The bike’s build and paint are predetermined, but geometry will be custom to the buyer. Order now, three of the 10 are already sold! Great work, Rob!

The bike’s build and paint are predetermined, but geometry will be custom to the buyer. Order now, three of the 10 are already sold! Great work, Rob!