Proti makes 6/4 Titanium bolts for motorcycles, using a technology where they are fully forged, including the threads. This relatively recent technology builds a bolt that has a much higher strength than a CNC cut bolt that is more typical of titanium bolts used in bicycles.

Proti makes 6/4 Titanium bolts for motorcycles, using a technology where they are fully forged, including the threads. This relatively recent technology builds a bolt that has a much higher strength than a CNC cut bolt that is more typical of titanium bolts used in bicycles.

Andre Szucs saw what this was doing in the motorcycle world, and worked with Proti to become the representative of the bolts for the bicycle industry, and started www.proti-bicycles.com. There is a lot of science that explains why forging is better than cutting, check inside for the story…

Simply put, titanium has about 60% of the density of steel. This means for a direct replacement bolt, using titanium can save a few grams off each bolt on your bike. The downside is that typical CNC cut titanium bolts are not quite as strong, and are more sensitive to being broken if not torqued the correct amount.

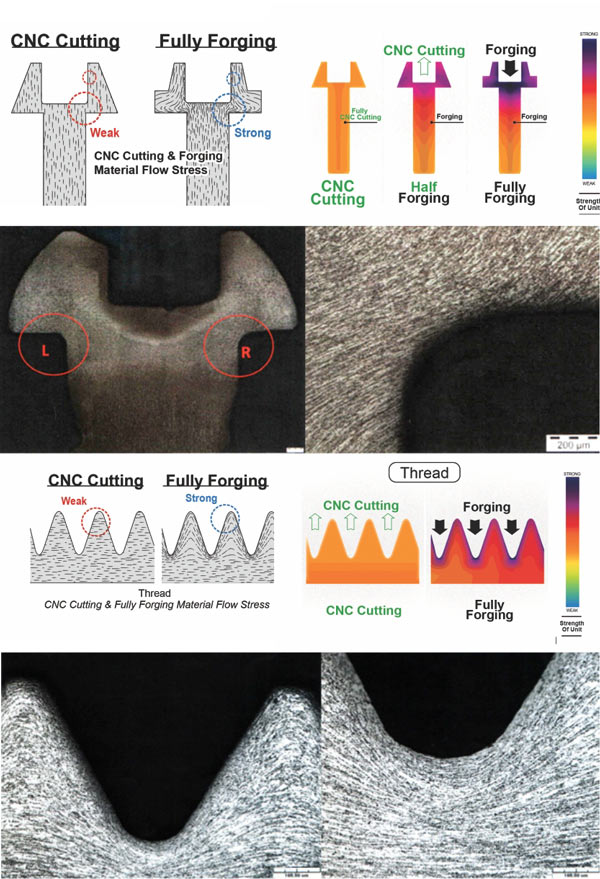

Proti uses a forging process to create the entire bolt. Forging pushes metal into shape under great force, which causes the grain structure of the metal to align with the part itself. Think of metal like wood, except at a very microscopic level. If you apply pressure across the grain of wood, it will be strong, if you apply pressure along the grain, it will split pretty fast. And in CNC cutting, there is no way to predict where the grain structure of the metal will be. Forging, and hence aligning the grain of the metal with the bolt, makes a stronger part.

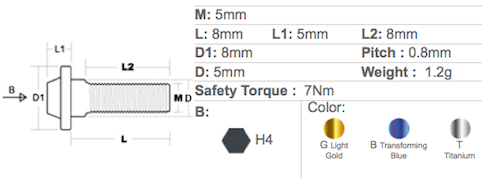

Proti, being from the motorcycle side, puts a lot of emphasis on material quality, strength and spec. The website information for each bolt is very comprehensive, something not typically seen in the bike industry. Every bolt is specified with all dimensions, weight and safety torque.

Keep in mind, safety torque is what the bolt is rated for, and if your component specifies a lower torque, you should use that. If your component specifies a higher torque, you probably should not use titanium bolts on that part. This is in stark contrast to the typical bicycle industry lack of information.

Keep in mind, safety torque is what the bolt is rated for, and if your component specifies a lower torque, you should use that. If your component specifies a higher torque, you probably should not use titanium bolts on that part. This is in stark contrast to the typical bicycle industry lack of information.

This quality comes at a price. A commonly used M6x16 bolt costs $9.13, but weighs 2.9g. Far exceeding the theoretical threshold of $1 per 1g savings talked about in bike forums, there are many lesser expensive ways to save weight on your bike. High quality and good manufacturing processes come at a price, so they may be worth it to you. Or, gold bolts are just too awesome not to have.