Years back, ENVE introduced the M-Series of wheels with various numbers to imply the intended use. The M50fifty was for XC, where you typically spent 50% of your time descending and 50% climbing. The M60forty and M7030 hit the middle ground and the M90ten handled downhill racing. Then last fall they upgraded those rim designs to reduce pinch flats and provide more refined ride quality with a wider bead and unique boundary layer on the widest models. Now, that same ride tuning and number scheme comes to the cockpit.

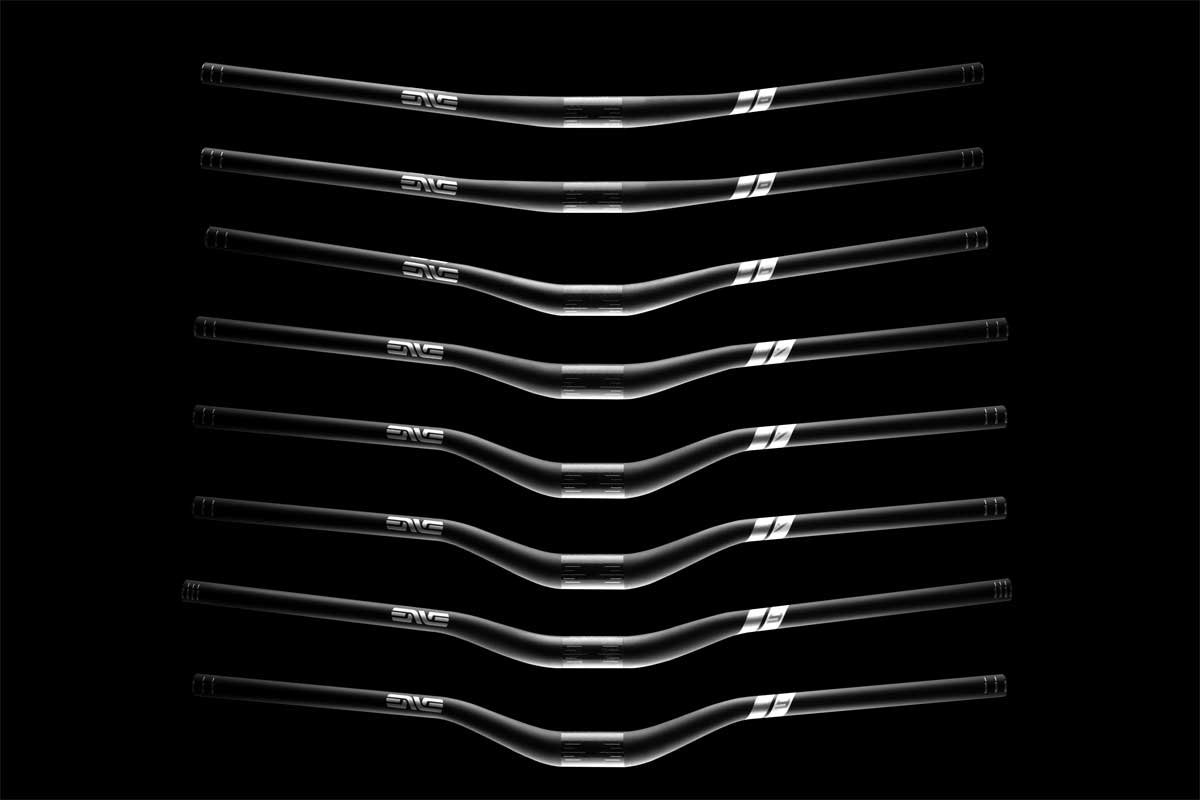

Ranging from M5 for XC to M6 for trail to M7 for enduro and M9 for DH, the new handlebar range gets use-specific layups, sizes and sweeps to balance strength, flex and width for a better ride. Several have both low- and high-rise options, and all have cut lines, though ENVE says they’re minimal because cutting them too short can reduce the intended benefits of their carbon tuning.

Check the full specs graph below for measurements, but note the different angles across models. ENVE’s rep said the Sweep was designed for the rider type, too. More aggressive riders will find less sweep to keep the front of the bike better weights for more traction and aggressive handling.

They said the 35mm bar was a challenge because they had to still make them feel good. The larger diameter makes it easy to make them overly stiff. So, it’s stiffer than the 31.8 bar, but it shouldn’t beat you up. If you want something with more give, stick with the 31.8 bars.

The faceplate uses a zero gap design on the top of the face plate, meaning you tighten the top two bolts until there’s contact, then torque the bottom bolts to spec. The M6 has an even gap top and bottom, but the new M7 stem is easier to install and make it foolproof for less technically inclined riders.

The new M7 stem uses a co-molded, bridged insert on the back, which provides a larger metal piece for the bolts to thread into…and now both bolts thread in from the same side. Compare that to the M6 stem, which carries on with individual, smaller threaded inserts that are offset left to right for top and bottom bolts. The M7 stems are made in Ogden UT, and they’re the future of ENVE’s stems.

Matching the new bars are updated stems, with their first 35mm bars and stem. They have a full carbon body with cold forged alloy face plate and titanium bolts.

(Bar widths didn’t make it in the chart from ENVE for some reason. They are M5-760mm, M6-780mm, M7-800mm, M9-810mm.)

“A carbon-bodied mountain stem capable of handling the abuses of enduro racing represents engineering challenges on multiple levels,” says ENVE Design Engineer Blake Jensen. “One, the stem must be exceptionally strong. Second, it needs to be lightweight and improve the ride. While the benefits of the carbon stem are more subtle compared to the noticeable ride improvement of our carbon bars, the combination of an M Series handlebar and stem produces a lightweight cockpit with an unmatched ride feel.”

In other words, they say alloy stems at this weight won’t hold up to this stem’s testing standard. Only the M7 bars will get the larger diameter clamp area, which will need to be paired with the M7 stem. The M9 is left at 31.8 and is most likely to be fitted to a direct mount stem on a dual crown DH fork. They admit that most of the ride quality improvement comes from the bar, but if you want that last 5% of ride quality improvement (or just a matching cockpit) then grab the stem, too.

All new M Series components are covered by ENVE’s Lifetime Ride Guarantee, which covers impact damage to wheels and components.