If it’s what’s on the inside that counts, the new 3D printed titanium dropouts now shipping on No22’s road bikes count for a lot.

Not only do they look as sleek and streamlined as those on carbon frames, they save them hours of machining and welding time during frame building. And they’ll save you loads of time and sanity when you’re building your bike or installing your brakes, too!

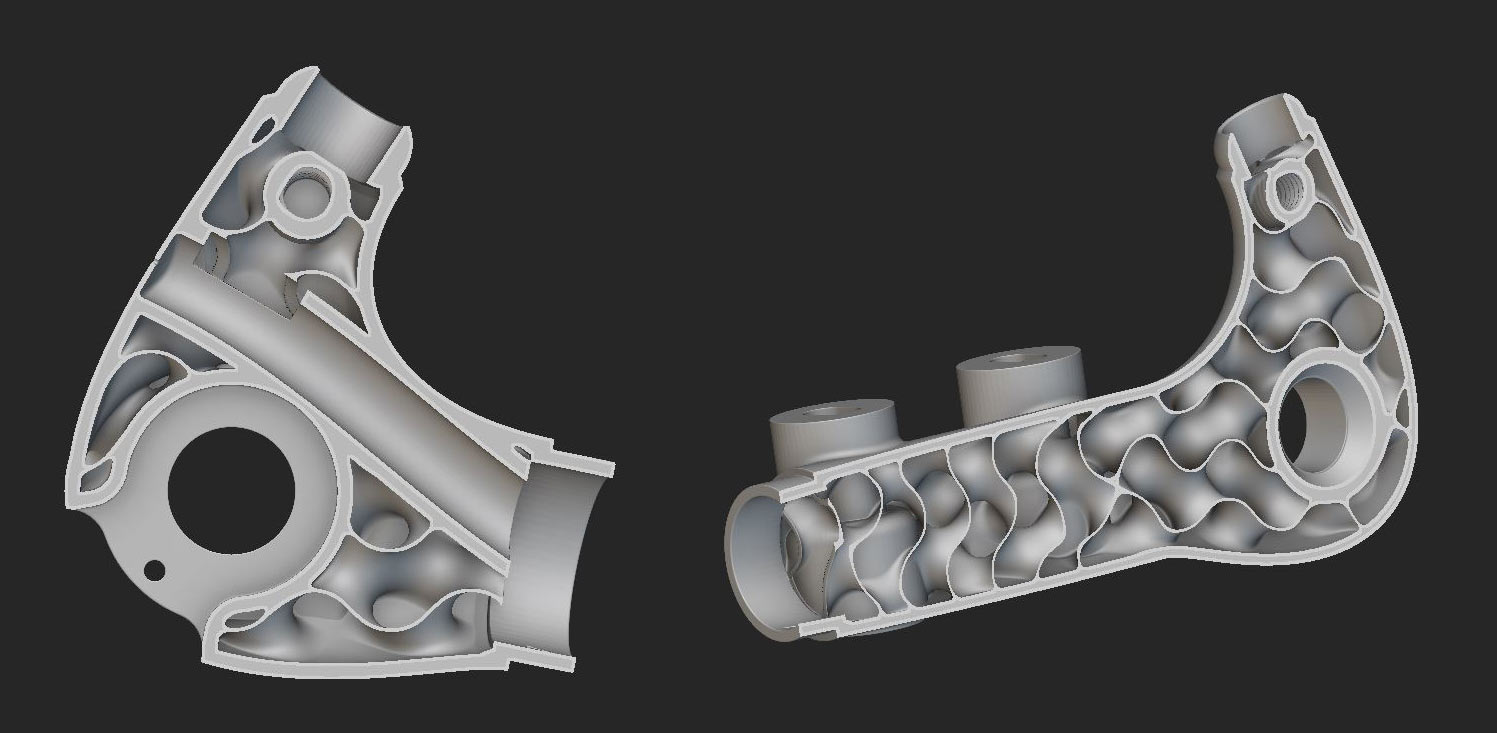

The 3D-printed, sintered titanium dropouts start with 6/4 titanium powder that’s essentially welded layer by layer into a part. Printed by Silca in Indiana, the dropouts get internal gyroid ribbing to reinforce the structure, yet also allow air to flow through them.

Or, more specifically, allowing argon gas to flow through them. They needed this capability to purge the oxygen out of the tubes to achieve clean, strong welds when attaching them to the seatstays and chainstays. Those welds are then smoothed to achieve a svelte appearance.

Fun fact: The raw ti powder can cost up to or more than $400/kg, so they say they’re incentivized to save as much weight as possible in the finished part!

They also printed a wire tube, allowing both Shimano Di2 and Campagnolo EPS wires to pass through easily. On the backside, it’s printed shut for ultra-clean wireless SRAM AXS installs, and they simply tap a hole to access the port for wired groups.

After printing, the part is sent to No22 for finishing, where they polish and smooth it slightly and face the brake mounts to ensure proper alignment. Not much is needed, though, as one of the key benefits of printing this part versus machining and welding multiple small parts is the accuracy it allows for.

Then they’re heat treated to increase fatigue strength, yielding a part that’s ≥99.5% as dense as a CNC’d billet 6/4 part, and just as strong and durable.

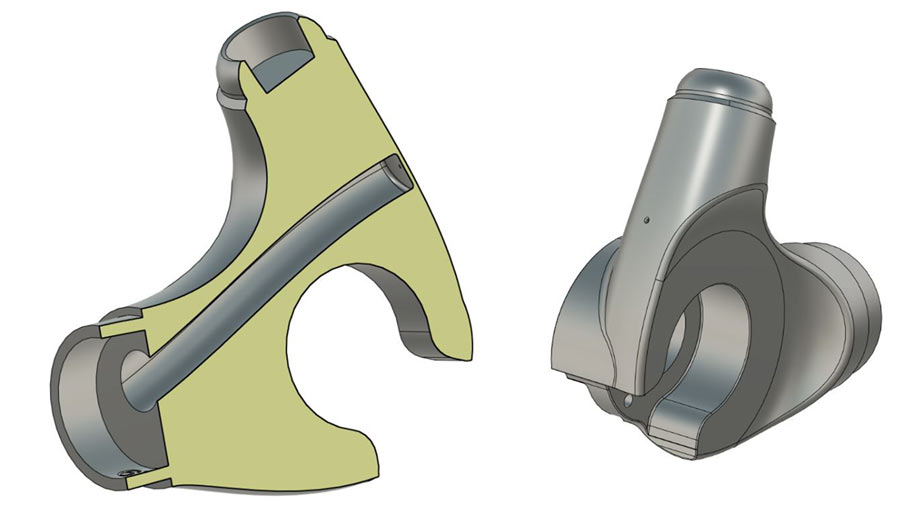

Shown above is the prior generation (on left), which used a shielded dropout, two flat mount brake mounting tubes, and a threaded insert. All told, it’s at least five welds of tiny parts that also require mitering to fit together.

While No22 prides itself on being able to produce those parts such that they are nearly perfectly aligned even after the multiple heating and cooling cycles of welding all those pieces together, it’s a pain in the butt. And it takes a really long time.

Cumulatively, these new 3D-printed dropouts save ~20 hours of highly skilled manpower per week and achieve a better, more perfectly aligned result. They’re also about 5x more expensive, but the saved labor just about washes it even, and they end up with a better performing (and arguably better looking) bike.

Look for these new dropouts now on their road and gravel bikes.