Specialized’s latest published patent documents a “Bicycle Frame with Angled Strut”, wherein a completely new frame tube – an ovalized strut connecting seat & down tubes – appears designed to deliver increased vertical flex compared to a conventional bicycle frame design with a continuous seat tube. This unusual design implies impacts for frame weight, ride comfort, and tire clearance, too, possibly giving us some insights into what a next generation of Specialized’s Spring Classics road racing bike, all-road, or even gravel bike might look like…

Specialized Patent for Bicycle Frame with Angled Strut

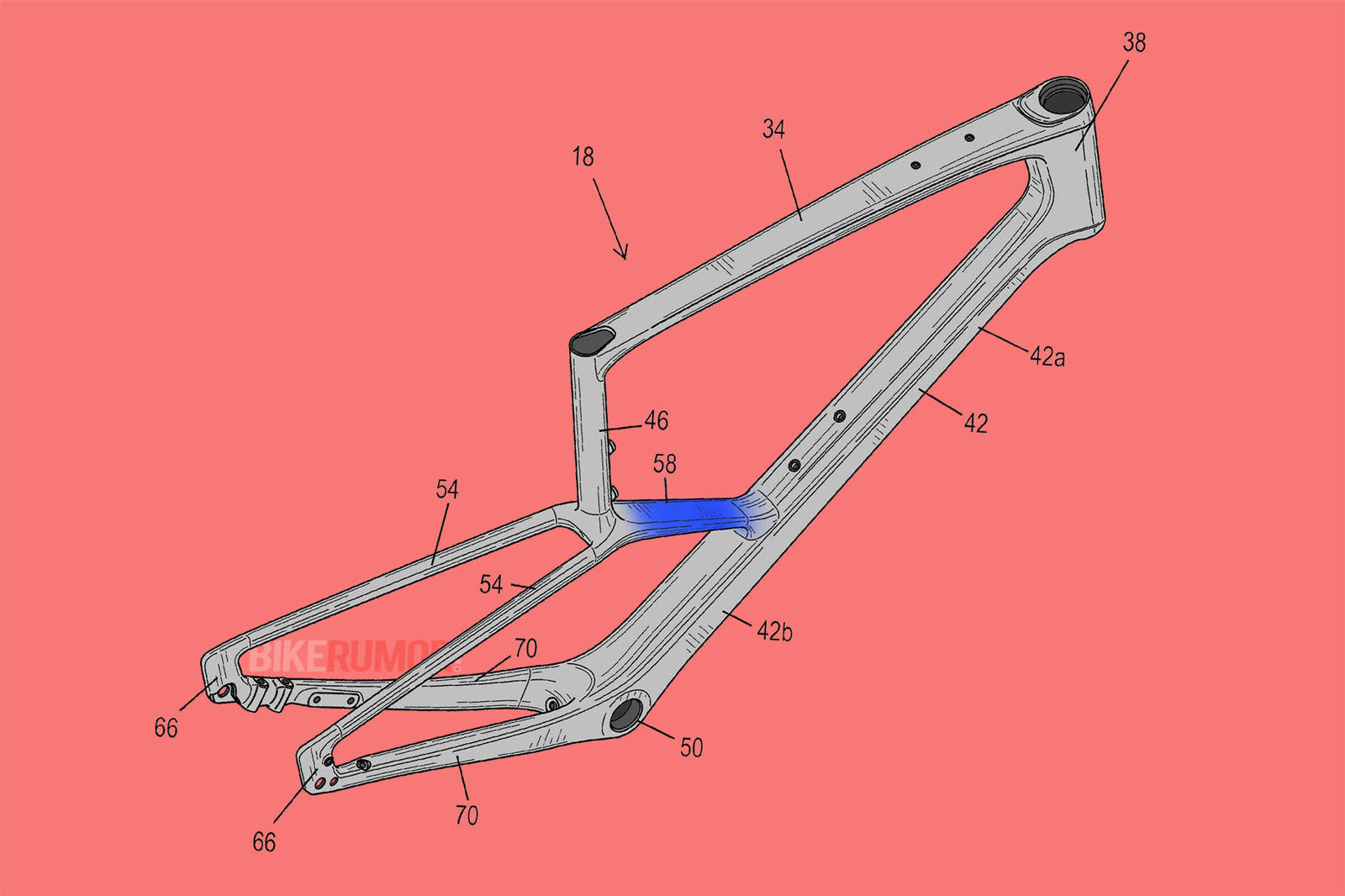

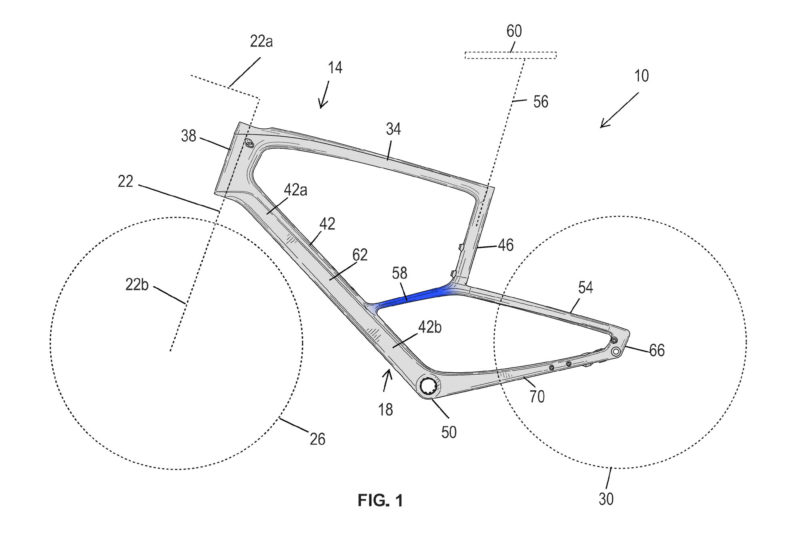

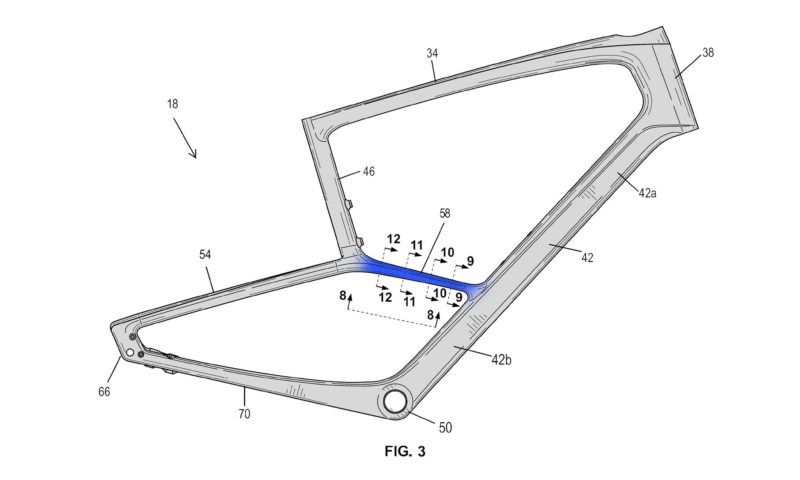

The bicycle frame outlined in this European patent from Specialized (EP4122807A1) does away with a continuous seat tube, replacing it with a sort of floating one, if you will, suspended by a portion of ovalized frame tubing that connects it to the downtube around a third of the way up the latter’s length (58). No more traditional frame triangles in this bike… might we refer to the front polygon & rear trapezoid in the future?

The patent claims that these modifications advantageously reduce the vertical stiffness of the bicycle while substantially maintaining or reducing to a lesser extent the horizontal (e.g., lateral or torsional) stiffness of the bicycle, thereby increasing the comfort for the rider while substantially maintaining or only slightly reducing the handling of the bicycle and/or force transfer of the rider to the bicycle.

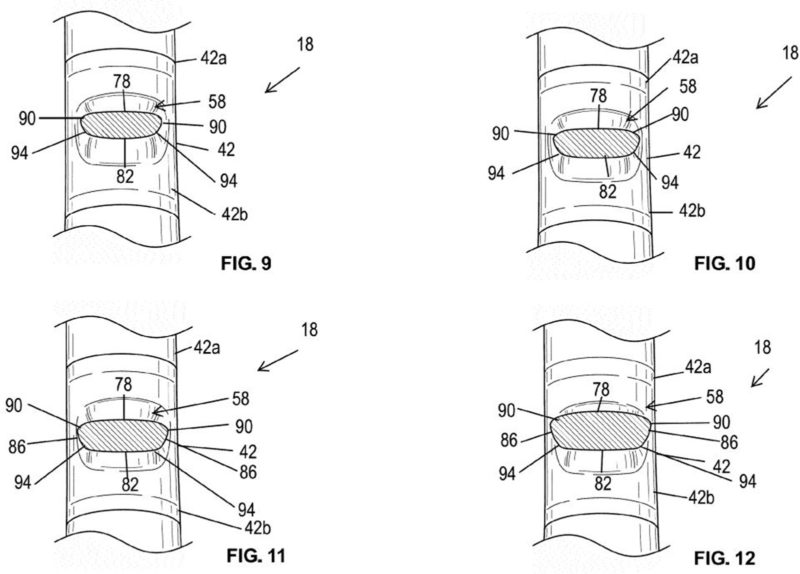

Use of ovalized tubing such as this is nothing new, of course. Plenty of modern bikes feature flattened tube profiles throughout for engineered vertical flex. Cotic for example has been using an ovalized steel top tube on its mountain bikes and gravel bikes for years, while OneUp’s Carbon Handlebar makes use of an ovalized section between the stem clamp and bar-end regions. In both cases, despite the use of very different materials, the idea is to increase vertical compliance to better isolate the rider from the smaller lumps and bumps on the trail.

Specialized interestingly mention the potential use of steel, aluminum, OR carbon fiber for this bicycle frame. Though, judging by the seamless of curves in the drawings, this is almost definitely intended to materialize in carbon. But that likely suggests that lower-cost versions could employ similar concepts in metal construction, too.

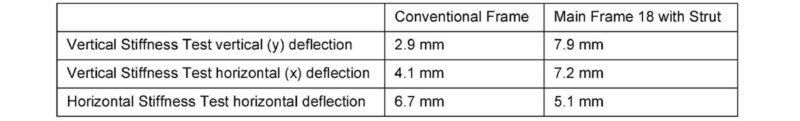

A table within the patent document suggests the angled strut gives the bike frame 172% more deflection in the vertical plane, and 75% more deflection in the horizontal plane – compared to a conventional frame with a regular seat tube that meets the downtube at the bottom bracket. They determined those numbers with a test simulation wherein the conditions were similar to those specified for ISO 4210-6:2015-4.5, or “Fatigue test with vertical force”.

In the Horizontal Stiffness Test simulating ISO 4210-6:2015-4.4 or “Fatigue test with horizontal force”, the Specialized frame with the angled strut is even slightly stiffer in the horizontal plane than the conventional frame.

The patent document reads, “By increasing vertical deflection at a greater rate than the horizontal deflection, ride comfort is increased without substantially increasing the rearward saddle tilt“.

How will this fit into Specialized’s Road & Gravel Bike line-up?

We approached Specialized for comment on this one, successfully securing the expected “No Comment” reply. Alas, we are left to hypothesize.

Let’s not forget that it was only in October of last year that Specialized released the wild-looking Diverge STR. In that design, the actual seat tube is the spring, while a Future Shock housed within the top tube damps a claimed 30mm of travel.

It’s unlikely the ‘Bicycle with Angled Strut’ described within Specialized’s latest patent document will go head-to-head against this latest Diverge STR. After all, we’re looking at smaller travel numbers of no more than 8mm here.

More likely, it is a contender for an update on the Spring Classics road racing Specialized Roubaix. The cobblestone-eating Roubaix does have the official tagline “Smoother Is Faster” on Specialized’s website.

Plus, it’s been four years since we rode, covered in mud into the velodrome where Paris-Roubaix finishes on a new Roubaix. It seems about time for a new version to debut in the pro peloton. We’ll certainly be keeping our eyes open for this bike. It’ll be hard to hide such a unique frame shape, even in training.

The comfort-oriented but still road-racing Roubaix has long been a platform for Specialized to experiment with unique vertical compliance tech – everyone remembers Zertz, right? Its latest iteration has a gen 2 Future Shock up front, and a floating/flexing aero seatpost out back. But this cropped seat tube could take comfort under your butt to a new level.

Aside from the improved comfort that may come with the increased vertical compliance, the new design could have implications for tire clearance, too. Specialized made much of their so-called ‘Clearance to Weight Ratio’ (CTR) when they released the latest Specialized Crux in 2021, claiming it was industry-leading in that regard. That evolved cyclocross & gravel frame weighs just 725g and allows for 700c x 47mm tires.

Perhaps without a seat tube to interfere above the bottom bracket, the layout could foreseeably allow for a subtle decrease in chainstay length without having a negative impact on tire clearance. And this new Bicycle Frame with Angled Strut could even end up boosting tire clearance for whatever category it ends up in – be that road, all-road, or gravel.

We shan’t hypothesize as to how exactly the angled strut frame design would impact weight. But, given that half of the seat tube is effectively missing, which previously would have directly supported the rider’s weight down to the bottom bracket – we’d presume there will need to be some additional material both to manage the flex and to physically support the rider.

If any of this unique flexing design has tickled your fancy, be sure to check out Lauf’s leaf spring rear suspension gravel bike concept for a very different solution to the same simplified vertical flex issue.