One of the best aspects of a show like MADE is the incredible variety of bikes that you will see. On one end of the spectrum, you’ll find classic frames painstakingly made with traditional techniques. On the other hand, you may find something like the Paladin AM1: a completely CNC-machined mountain bike frame made in Portland.

The Paladin team’s origin story follows an arc that is somewhat familiar at this point. After establishing themselves as top-notch machinists for a robotics start-up firm, Paladin’s founders utilized mountain biking as their escape from work-related stress. That led them to consider using their CNC talents to create bike components, but they realized that they could take it a step further with a complete frame, which eventually resulted in the AM1.

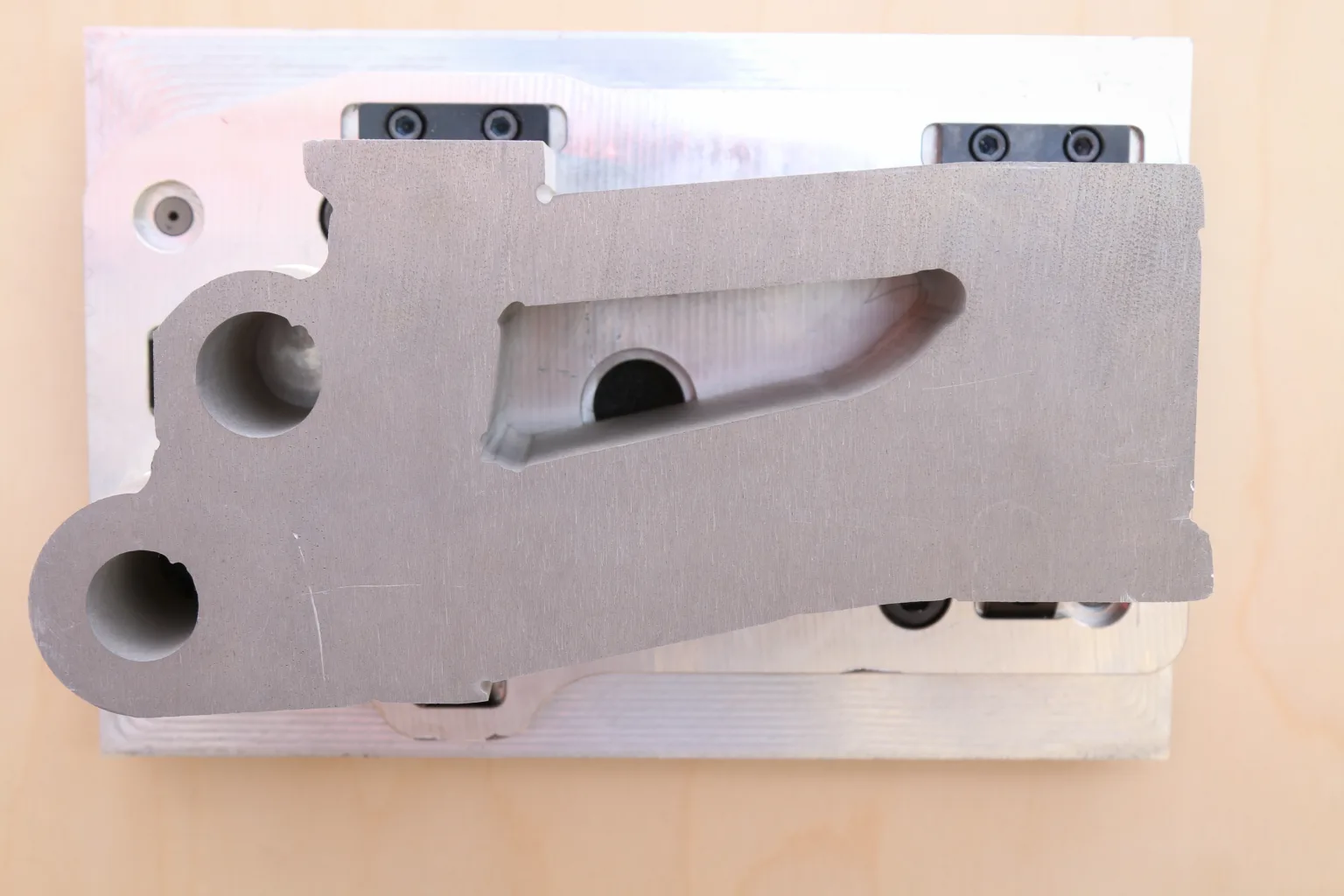

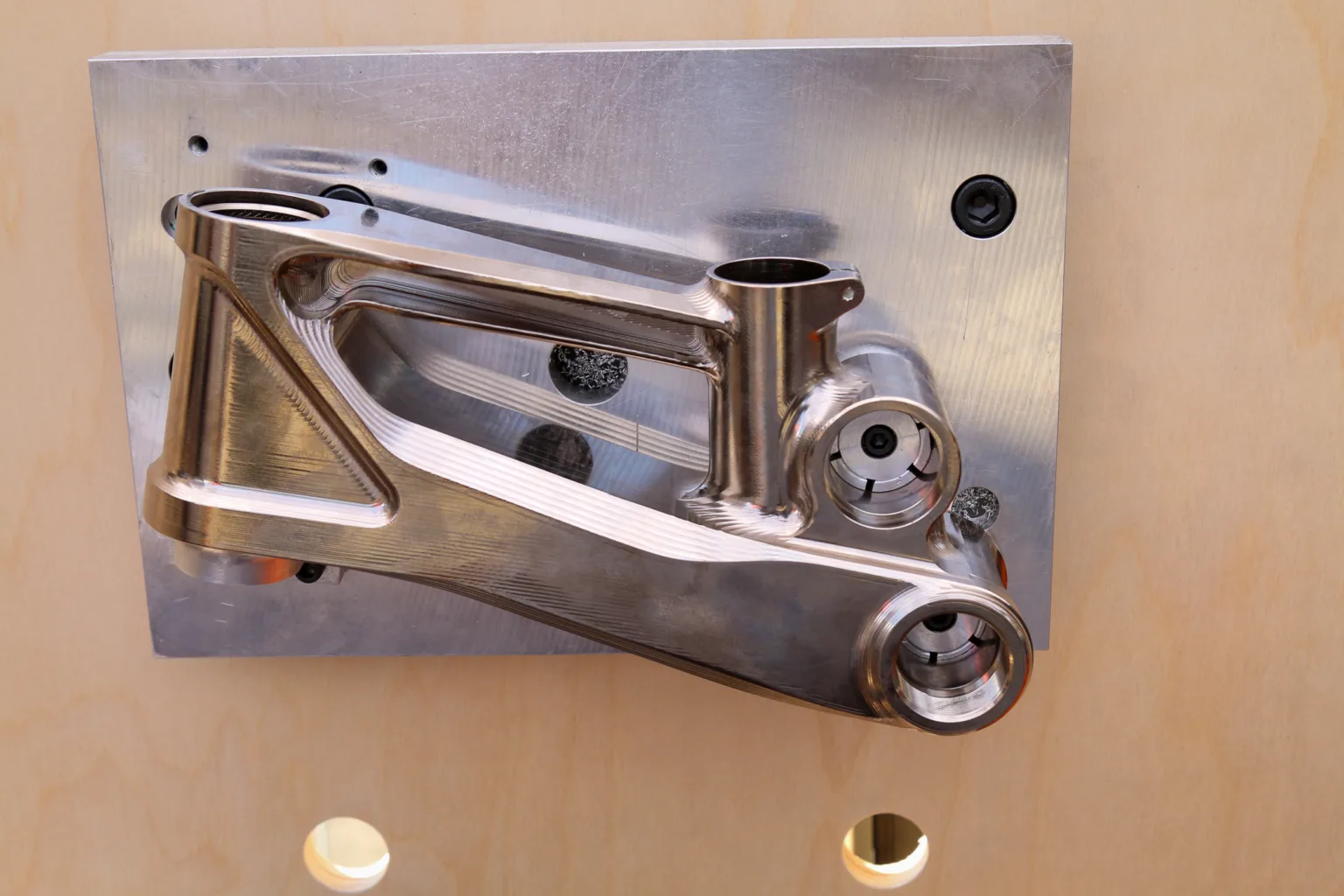

According to Paladin, they utilize a new, patent-pending process to machine the frame using multi-axis CNC machines. Their process allows the front triangle to be machined in one go, with the machine touching all sides of the frame without having to move it in the fixture. The top tube is hollowed out from the sides like an I-beam, the seat tube is drilled out, and the downtube is “hollowed out and closed up with a durable double-lap shear joint.”

Paladin also points out that the frame is machined from 7075 aluminum, which is stronger and more durable than 6061 aluminum, which is more commonly used for frames that are welded. Starting with a Horst link design originally, the team found that the chain stay design had to be weaker than desired to make that suspension layout work. So they moved to the new design with an elevated chainstay and the pivot farther up the ‘chainstay’. This gave the frame the strength they were looking for, and has the added benefit of being quieter due to reduced chainslap.

The AM1 has the option of running different stroke and length shocks for different travel numbers, with builds expected to be offered in 140mm rear/150mm front, or 150mm rear/160mm front travel. Riders will also have a choice in rear wheel size with 27.5/29″ options for an MX build, or full 29″. Machined to order, without any molds or tooling for hydroforming, Paladin states that they can easily make changes to geometry, including 6 different rear-center length options.

Completely machined next door to their office in Portland, Oregon, the raw aluminum frames have a protective enamel finish for now. But Paladin states that they are researching additional finishes, but not to expect any full color anodizing or anything like that for now.

Currently in the final testing phase, the AM1 has one last round of engineering testing, but the frame has already been put through its paces with aggressive riding. Paladin expects bikes to be ready to sell starting early next year for the 2026 riding season, with prices TBD.